Preparation method of free-agglomeration MgAl2O4 nanometer particle powder

A nanoparticle and powder technology is applied in the field of preparation of non-agglomerated MgAl2O4 (magnesium aluminum spinel) nanoparticle powder, which can solve problems such as unfavorable densification and sintering of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

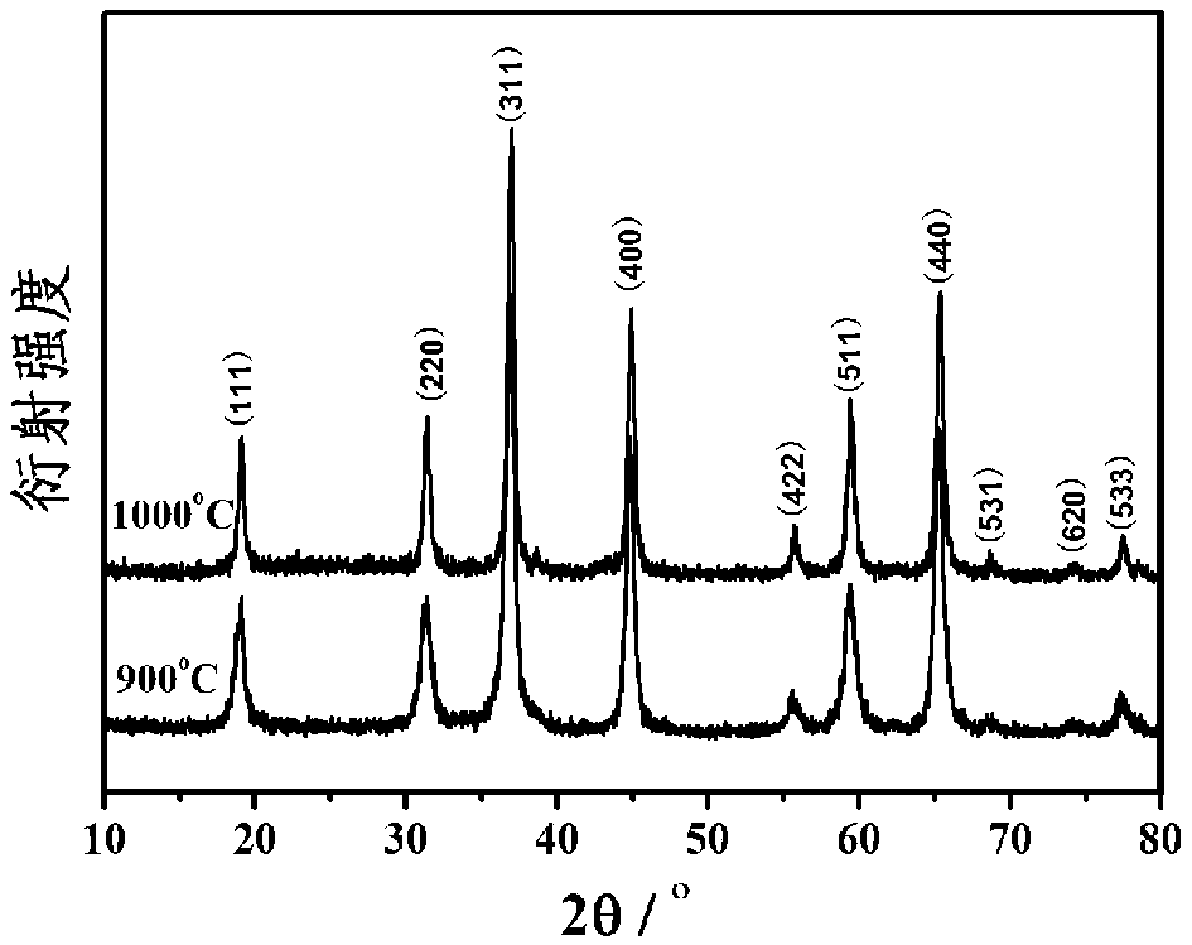

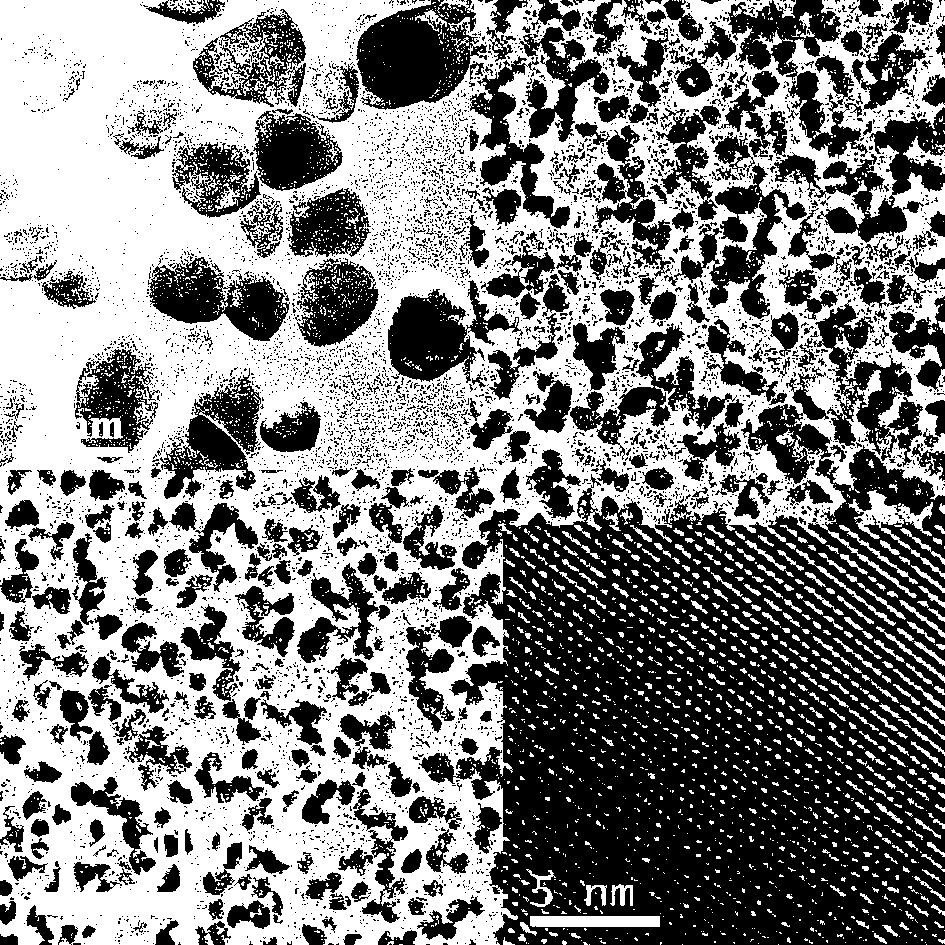

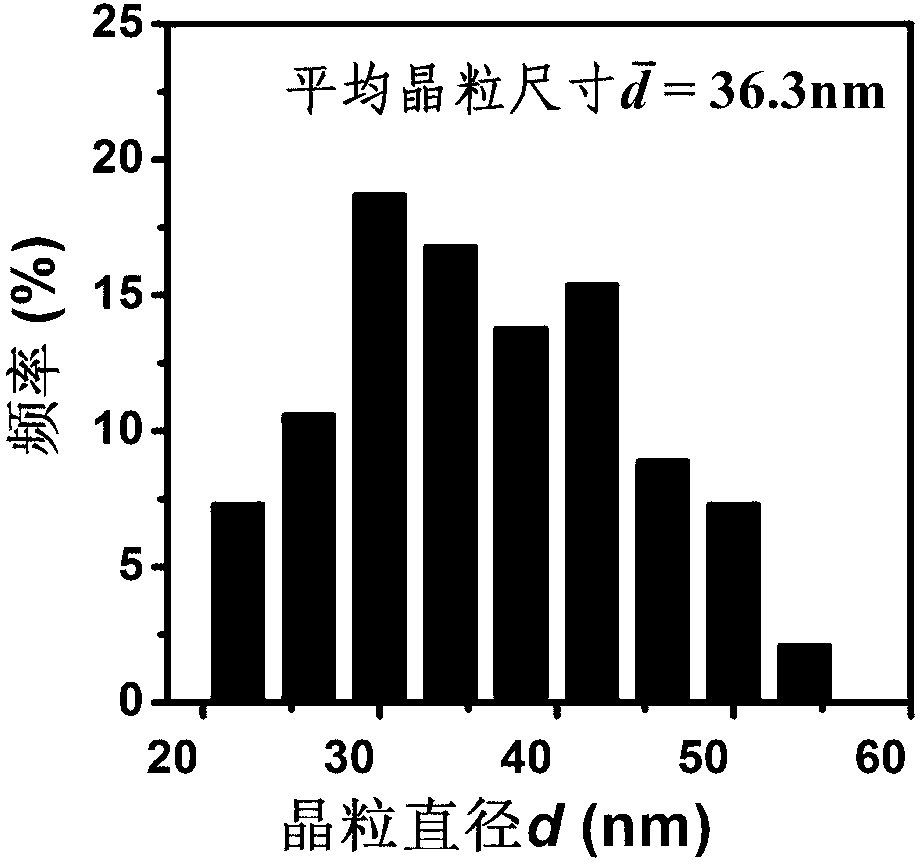

[0018] The present invention prepares MgAl 2 o 4 The method of nanoparticle powder is to dissolve soluble magnesium salt and aluminum salt in distilled water to prepare Al 3+ The concentration is 0.005~0.5mol / L, Mg 2+ / Al 3+ The ratio of the amount of substances is a mixed brine solution of 5 to 40, and the magnesium salt used can be Mg(NO 3 ) 2 , MgSO 4 , the aluminum salt used is Al(NO 3 ) 3 、Al 2 (SO 4 ) 3 . Then add network agent (C 3 h 5 NO, C 7 h 10 N 2 o 2 ), after being uniformly mixed by mechanical stirring, the initiator [(NH 4 ) 2 S 2 o 8 ] Initiate the polymerization reaction of the polymer network agent, and the polymer three-dimensional network formed in the mixed saline solution makes the mixed system into a wet gel. The wet gel was dried at 80oC in a drying oven to obtain a xerogel (MgAl 2 o 4 Precursor). Then the dry gel was calcined at 850~1000oC for 1~10 h, and the calcined product was washed with acid and water to obtain non-agglomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com