A design system and method for thermal power generation projects

A design system and design method technology, applied in software design, design optimization/simulation, calculation, etc., can solve problems such as the inability to realize real-time data sharing, and achieve the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

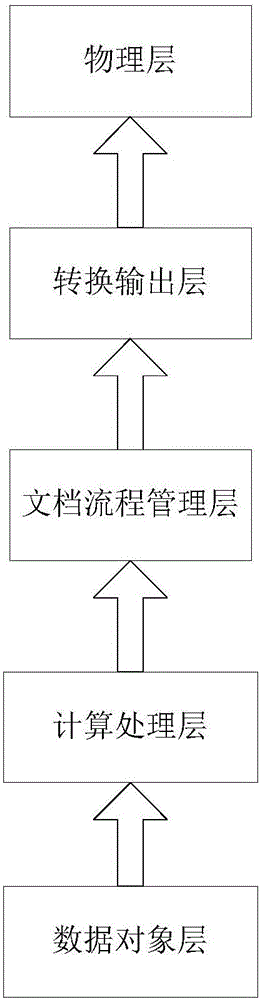

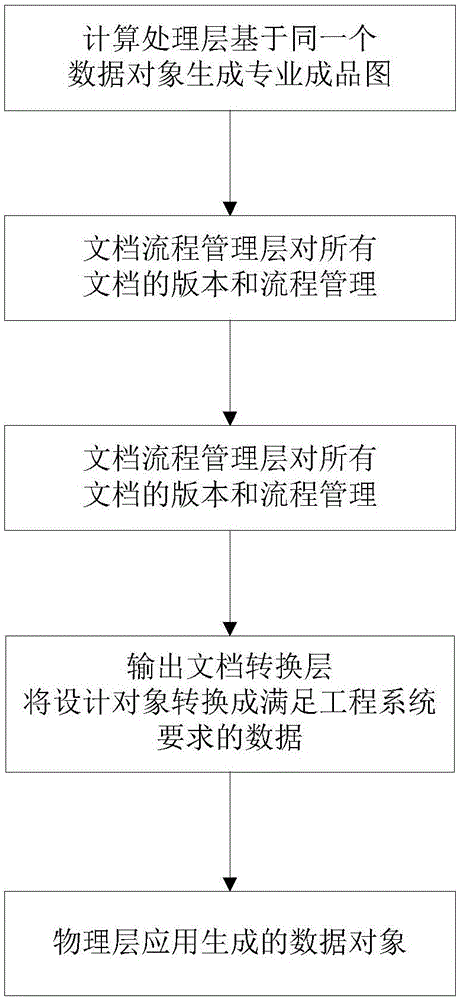

[0030] Such asfigure 1 The design system of the thermal power generation project of the present invention is shown, and the system hierarchy includes a data object layer, a calculation processing layer, a document flow management layer, a conversion output layer and a physical layer from bottom to top, wherein

[0031] (1) The data object layer includes: KKS (power plant identification system) code, static attributes, association relations and document structure;

[0032] The KKS code is the unique identification of the design object in the system. All design objects (such as valve actuators, pipe fittings, cables, etc.) have their own KKS code, and the code depth should reach the component level.

[0033] The static attributes include the specifications and calculation results of the design objects involved in the process, thermal control, thermal engine, and electrical disciplines. Taking the condensate pump object as an example, the design object includes not only the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com