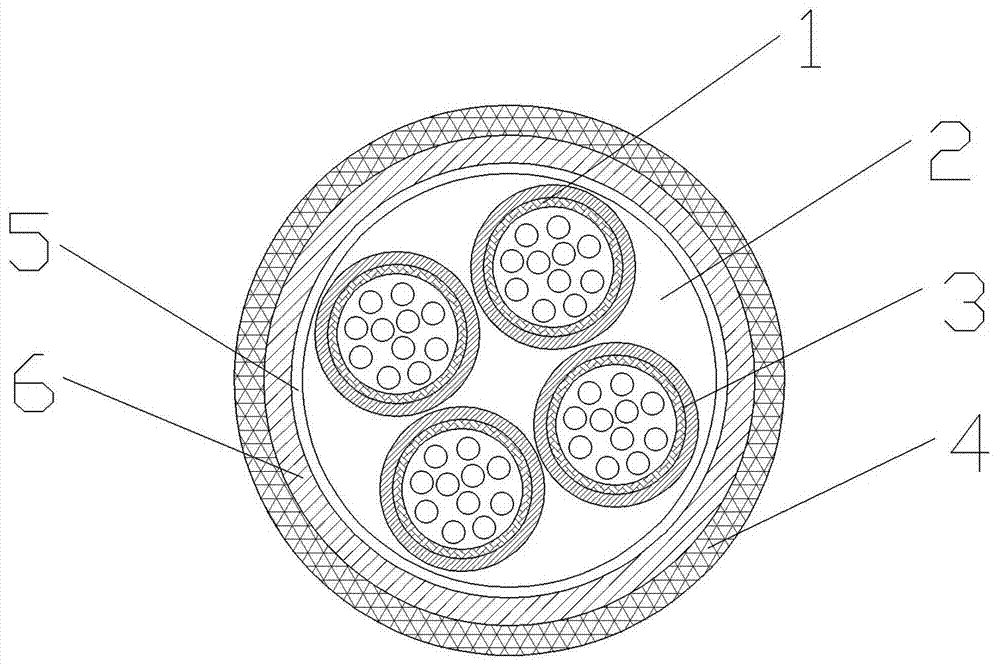

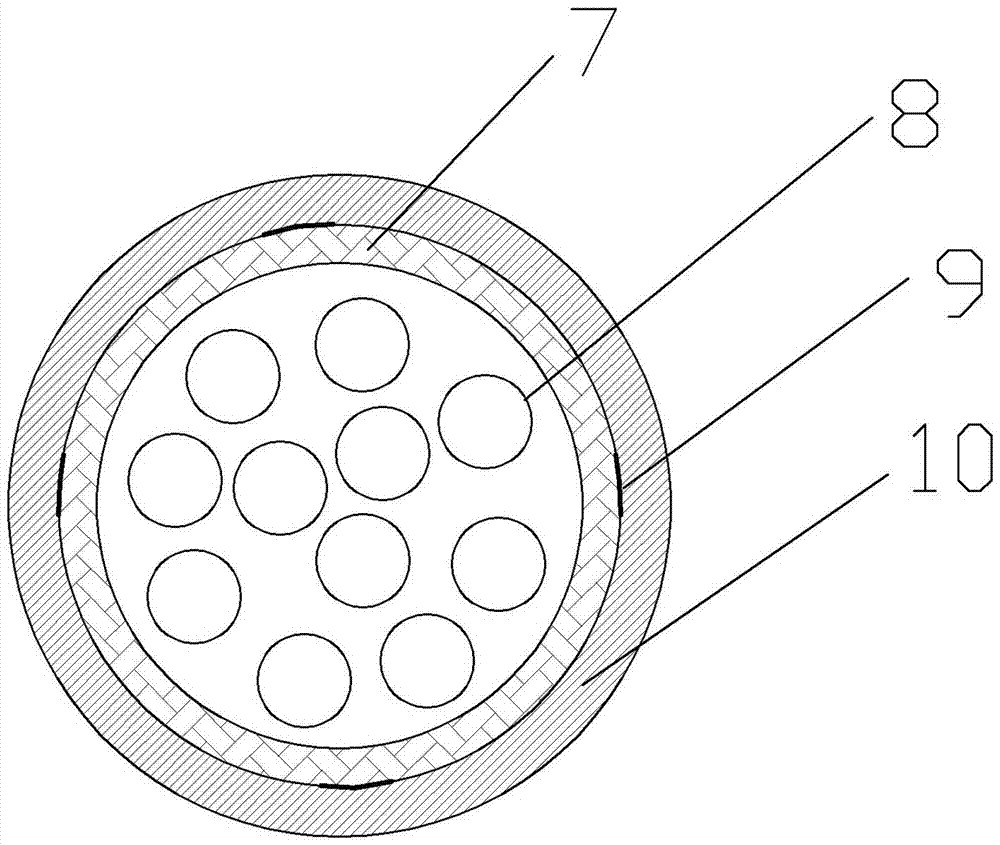

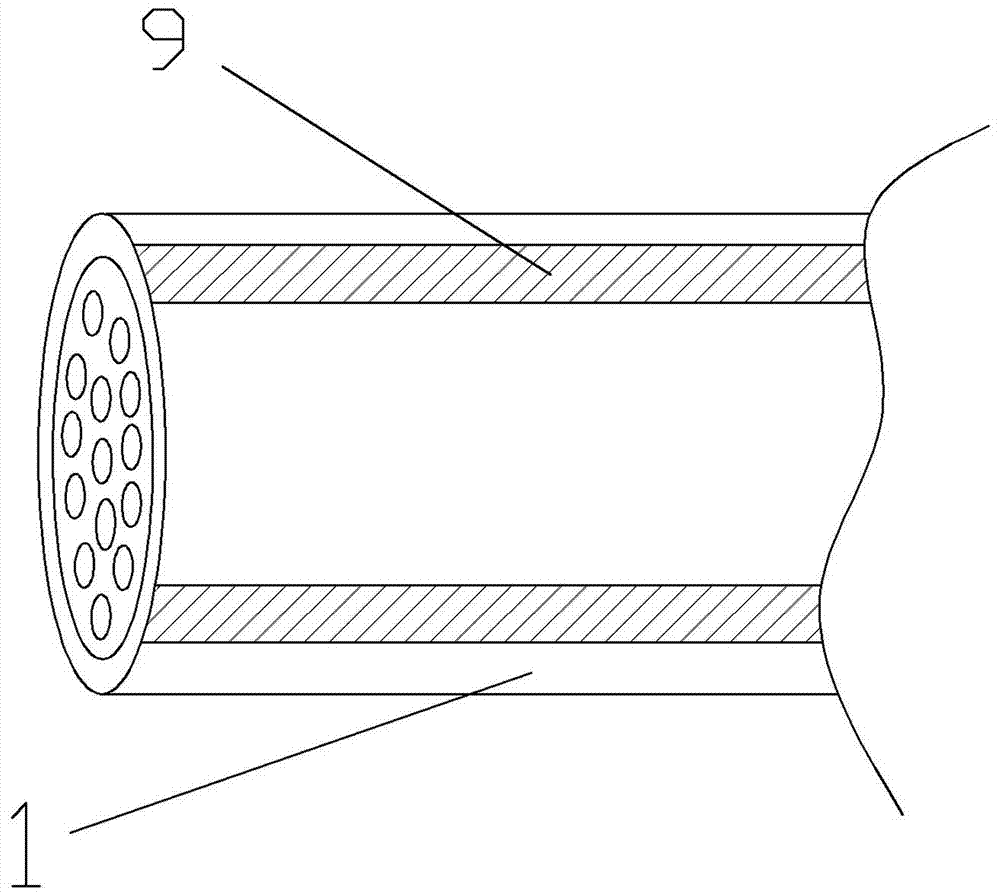

A kind of flexible fireproof cable and preparation method thereof

A fire-resistant cable and flexible technology, applied in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of inability to produce large lengths, affect fire performance, and small bending performance, and achieve continuous large-length production and production. The effect of low cost and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation method of the flexible fireproof cable of embodiment 1 of the present invention, comprises the steps:

[0049] (1) Preparation of ceramic polyolefin outer sheath material,

[0050] 50 parts of EVA260, 50 parts of ethylene-octene copolymer, 3 parts of EVA blend grafted with maleic anhydride, 20 parts of aluminum hydroxide, 30 parts of magnesium hydroxide, 0.2 parts of tetraerythritol ester, 3 parts of polyethylene wax and 2 parts of ultra-high molecular weight polysiloxane were added to an internal mixer and mixed for 15 minutes to 110°C to obtain a mixture A;

[0051] Add 300 parts of clay and 2 parts of simethicone 201 to the above mixture A, and banbury for 8 minutes to 145°C to obtain mixture B;

[0052]Add 60 parts of ceramic powder and 8.5 parts of EVA-based color masterbatch to the above mixture B, banbury for 30 minutes to 165°C, stop banbury, ceramicize the polyolefin outer sheath material, cool to room temperature, and set aside;

[0053] (2) ...

Embodiment 2

[0059] The preparation method of the flexible fireproof cable of embodiment 2 of the present invention comprises the following steps:

[0060] (1) Preparation of ceramic polyolefin outer sheath material,

[0061] 30 parts of EVA260, 20 parts of ethylene-octene copolymer, 1 part of EVA blend grafted with maleic anhydride, 10 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, 0.1 part of tetraerythritol ester, polyethylene wax 1 1 part and 1 part of ultra-high molecular weight polysiloxane were added to an internal mixer and mixed for 10 minutes to 100 ° C to obtain a mixture A;

[0062] Add 200 parts of pottery clay and 1 part of simethicone 201 to the above mixture A, and banbury for 6 minutes to 135°C to obtain mixture B;

[0063] Add 20 parts of ceramic powder and 5 parts of EVA-based color masterbatch to the above mixture B, banbury for 15 minutes to 145°C, stop banbury, ceramize the polyolefin outer sheath material, cool to room temperature, and set aside;

[...

Embodiment 3

[0070] The preparation method of the flexible fireproof cable of embodiment 3 of the present invention comprises the following steps:

[0071] (1) Preparation of ceramic polyolefin outer sheath material,

[0072] 70 parts of EVA260, 80 parts of ethylene-octene copolymer, 8 parts of EVA blend grafted with maleic anhydride, 50 parts of aluminum hydroxide, 50 parts of magnesium hydroxide, 0.1 part of tetraerythritol ester, polyethylene wax 5 1 and 2 parts of ultra-high molecular weight polysiloxane were added to an internal mixer and mixed for 15 minutes to 120°C to obtain a mixture A;

[0073] Add 400 parts of pottery clay and 2 parts of simethicone 201 to the above mixture A, and banbury for 20 minutes to 155°C to obtain mixture B;

[0074] Add 120 parts of ceramic powder and 15 parts of EVA-based color masterbatch to the above mixture B, banbury for 40 minutes to 165°C, stop banburying, ceramize the polyolefin outer sheath material, cool to room temperature, and set aside;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com