A surface-treated modified lithium-rich manganese-based layered positive electrode material and its preparation method

A positive electrode material and surface treatment technology, applied to battery electrodes, structural parts, electrical components, etc., can solve problems such as poor rate performance, cycle capacity attenuation, and large irreversible capacity loss for the first time, and achieve high capacity, stable internal structure, and elimination of The effect of oxygen deficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Another object of the present invention is to provide a method for preparing the above-mentioned surface-treated modified lithium-rich manganese-based layered positive electrode material, the method comprising the following steps:

[0027] Step 1. Prepare the mixture: according to the molecular formula Li[Li x Mn 1-x-y M y ]O 2 The ratio of , the theoretical calculation ratio is (Mn 1-x-y M y ) hydroxide precursor and lithium hydroxide are added into the mixing tank for full mixing and stirring until uniform, and the element composition is Li[Li x Mn 1-x-y M y ]O 2 mixture;

[0028] Step 2. Sintering treatment: the elemental composition obtained in step (1) is Li[Li x Mn 1-x-y M y ]O 2 The mixture was heated to 400-450°C for 1-4h at a heating rate of 5-10°C / min, and then sintered at a constant temperature of 600-1000°C for 10-30h at a heating rate of 5-10°C / min. After the reaction was completed , the sintered product is ball-milled to obtain a lithium-rich ...

Embodiment 1

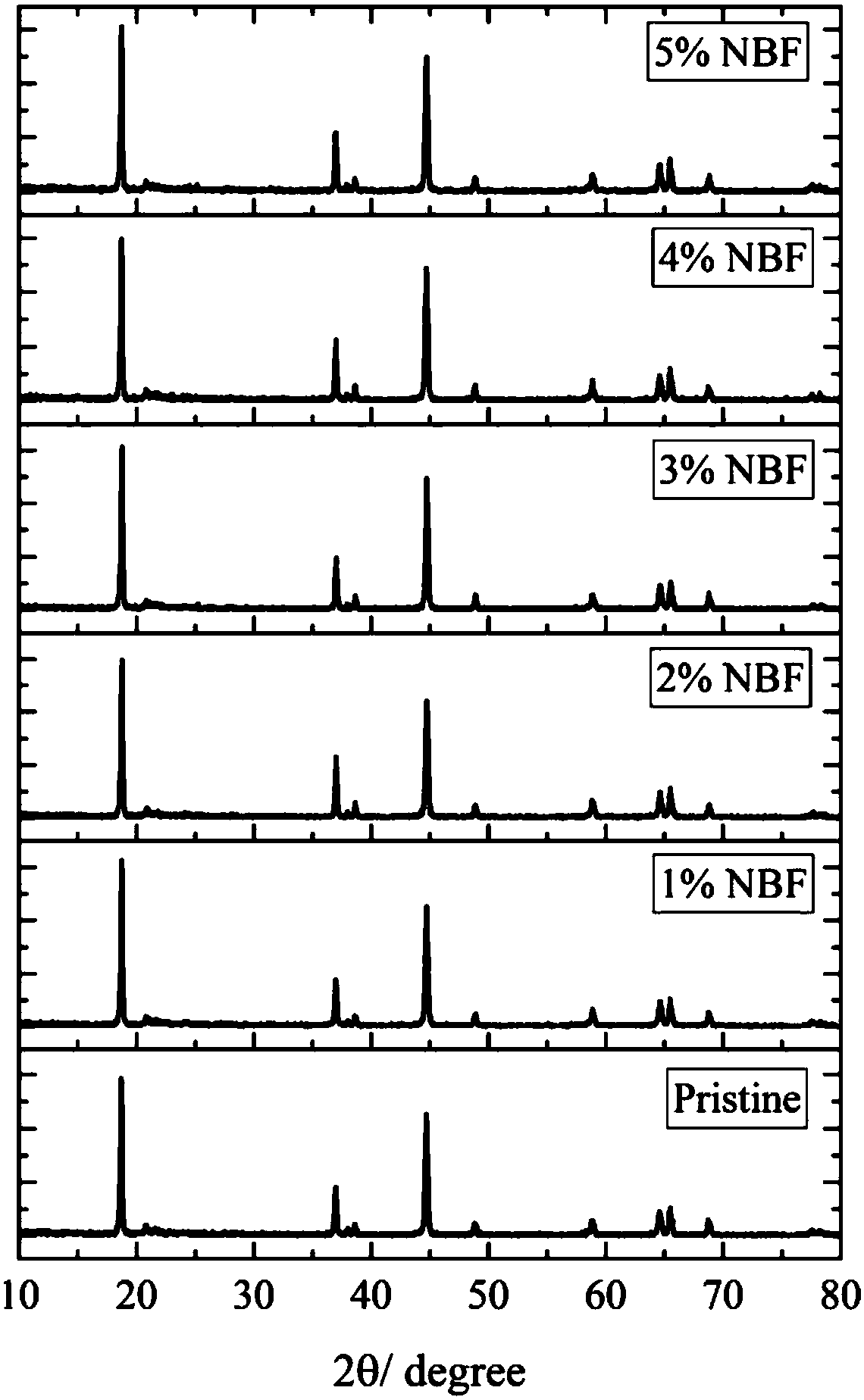

[0033] NH of this embodiment 4 BF 4 Coated lithium-rich manganese-based layered lithium-ion battery cathode material, is in the chemical formula Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 The outer surface of the layered Li-rich manganese-based cathode material conducts NH 4 BF 4 Treatment; in the example the treatment amount is NH 4 BF 4 / Li[Li 0.2 Mn 0.54 Ni0 .13 Co 0.13 ]O 2 The mass ratio of 3%.

[0034] Its preparation method is:

[0035] Step 1. Prepare the mixture: Li according to the molecular formula 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 The ratio of 10g of hydroxide precursor with molar ratio of Ni:Co:Mn=13:13:54 and 7.3g of LiOH·H with a purity of 96% 2 O, added to the mixing tank, mixed uniformly, and the element composition was Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 mixture;

[0036] Step 2. Sintering and grinding: The elemental composition obtained in step 1 is Li 1.2 Ni 0.13 Co 0.13 Mn 0.54 O 2 The mixture was kept at 450 °C for 1 h at a heating rat...

example 3

[0040] NAF / Li[Li of Example 3 0.2 Mn 0.54 Ni 0.13 Co 0.13 ]O 2 =2%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com