A kind of preparation method of NAF-coated lithium-rich manganese-based layered cathode material

A cathode material, lithium-rich manganese technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of capacity decay, low first efficiency, poor rate performance, etc., and achieve improved discharge capacity, low raw material cost, and stable crystal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

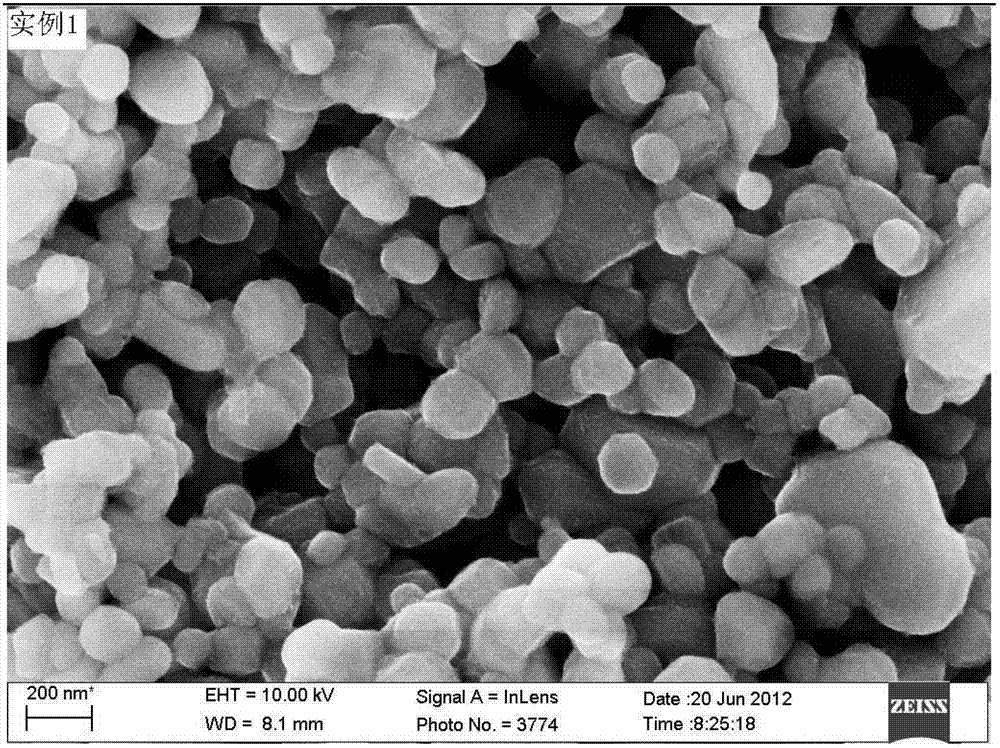

Embodiment 1

[0031] The NAF coating lithium-rich manganese-based layered lithium-ion battery positive electrode material of the present embodiment is that the chemical formula is Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 The outer surface of the lithium-rich manganese-based cathode material with a layered structure is coated with NAF; in the example, NAF is a pure phase (NH 4 ) 3 AlF 6 , the coating amount is NAF / Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 The mass ratio is 1%.

[0032] Its preparation method is:

[0033] (1) Prepare the mixture: according to the molecular formula, it is Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 The ratio of the molar ratio of Mn:Ni:Co=54:13:13 hydroxide precursor 10g and 7.3g of 96% purity of LiOH·H 2 O, added to the mixing tank, mixed evenly, to obtain the elemental composition as Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 mixture;

[0034] (2) Sintering and grinding: the element composition obtained in step (1) is Li[Li 0.2 mn 0.54 Ni 0.13 co...

example 2

[0038] In example 2 and example 3, except NAF / Li[Li in step (2) 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Except that the mass ratio is different, other experimental steps are all the same as example 1, wherein in example 2 NAF / Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 =3%, NAF / Li[Li in Example 3 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 =5%.

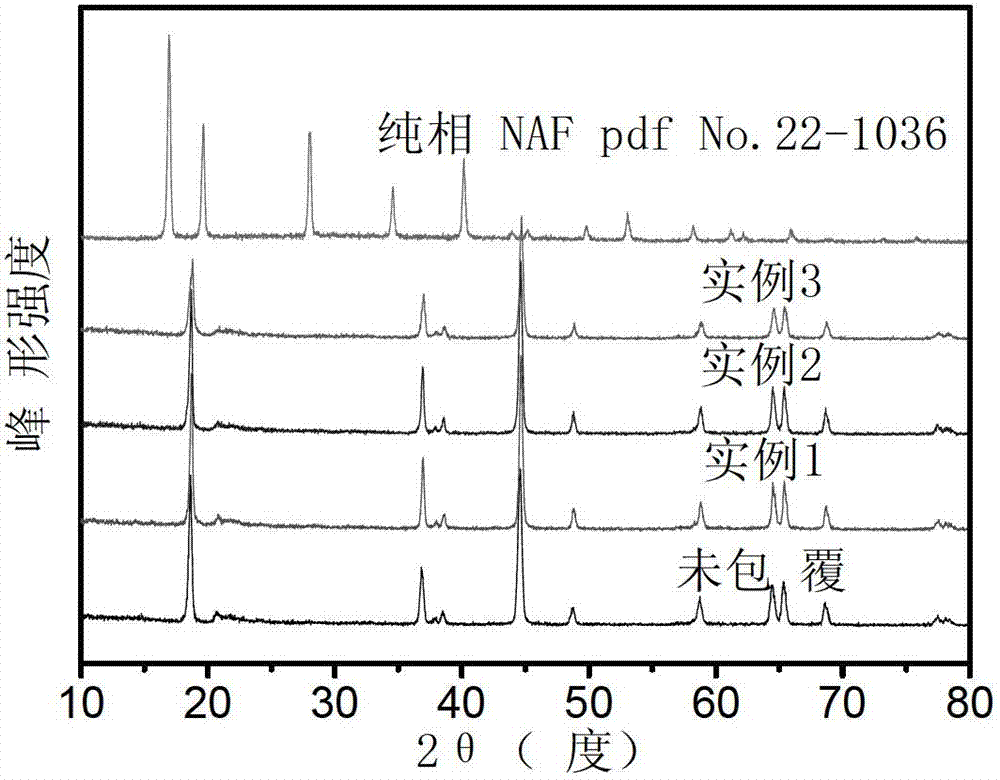

[0039] XRD pattern analysis

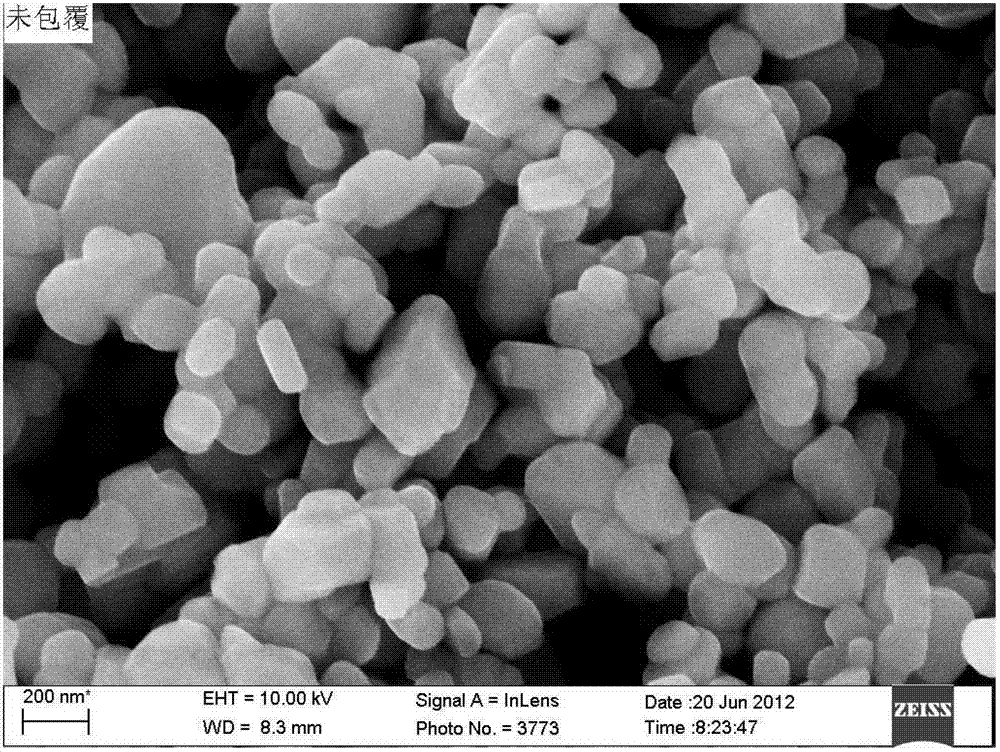

[0040] The NAF-coated lithium-rich manganese-based layered lithium-ion battery positive electrode material obtained in the embodiment, the manganese-based layered layered positive electrode material obtained in step (2) and the pure NAF obtained under the same conditions were subjected to XRD analysis. The results are as follows: figure 1 As shown, it shows that the coating is pure phase NAF. The NAF coated lithium-rich manganese-based layered lithium-ion battery positive electrode material obtained in the example and the lithium-rich manganese-based layered layered positive electrode material obtained in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com