A low-temperature sintered scintillator material and its preparation method

A scintillator material and low-temperature sintering technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of high sintering temperature, achieve good performance, simple preparation method, and increase light yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

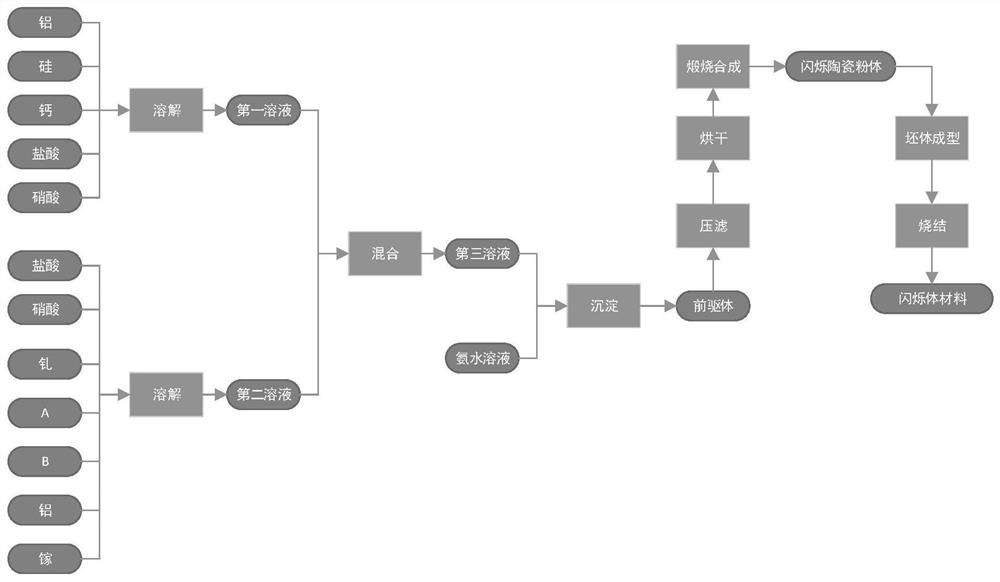

[0030] Please check figure 1 , a method for preparing a low-temperature sintered scintillator material in this embodiment, comprising the following steps:

[0031] (1) Prepare the first solution: dissolve aluminum, silicon, and calcium in a mixed solution of concentrated hydrochloric acid and nitric acid to obtain the first solution; the molar ratio of aluminum, silicon, calcium, and acid is 0.93-1.6:0.2-0.5:0.2 -0.6:4.8-12;

[0032] (2) Preparation of the second solution: dissolving gadolinium, A, B, aluminum, and gallium in a mixed solution of concentrated hydrochloric acid and nitric acid to obtain a second solution, wherein A is at least one of lanthanum, lutetium, and yttrium or a combination thereof Ingredient, B is at least one or a combination of cerium, praseodymium, neodymium, promethium, samarium, europium, terbium, dysprosium, holmium, erbium, thulium, ytterbium;

[0033] The molar ratio of gadolinium, A, B, aluminum, gallium and acid is 0.95-2.999:0.001-2:0.001-...

Embodiment 2

[0041] A method for preparing a low-temperature sintered scintillator material in this embodiment includes the following steps:

[0042] (1) Prepare the first solution: dissolve aluminum, silicon, and calcium in a mixed solution of concentrated hydrochloric acid and nitric acid to obtain the first solution; the molar ratio of aluminum, silicon, calcium, and acid is 0.93-1.6:0.2-0.5:0.2 -0.6:4.8-12;

[0043] (2) Preparation of the second solution: dissolving gadolinium, B, aluminum, and gallium in a mixed solution of concentrated hydrochloric acid and nitric acid to obtain a second solution, wherein B is cerium, praseodymium, neodymium, promethium, samarium, europium, terbium, and dysprosium , holmium, erbium, thulium, ytterbium at least one or a combination thereof;

[0044]The molar ratio of gadolinium, B, aluminum, gallium and acid is: 0.95-2.999:0.001-0.05:2-4:1-3:14.22-54.22;

[0045] The concentrated hydrochloric acid concentration is 37%, the concentrated nitric acid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com