Absolute position signal calibration system of hybrid photoelectric encoder and method thereof

A photoelectric encoder, absolute position technology, applied in control systems, vector control systems, control electromechanical brakes, etc., can solve the problems of large influence on the starting performance of the servo motor, affecting the control performance of the servo system, and low accuracy of the absolute position signal, etc. To achieve the effect of easy promotion and use, saving manpower and material resources, and high calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

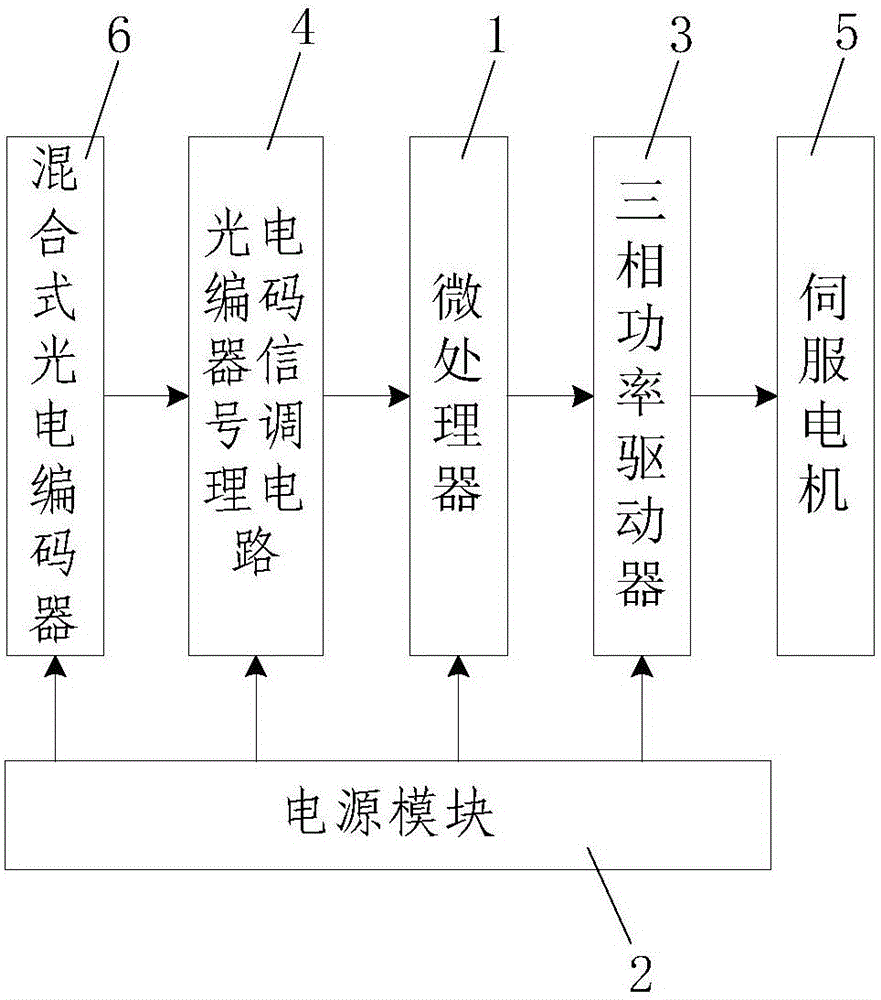

[0034] Such as figure 1 As shown, the absolute position signal calibration system of the hybrid photoelectric encoder of the present invention includes a microprocessor 1 and a power supply module 2 for powering each power unit in the system, and the input terminal of the microprocessor 1 is connected with a The photoelectric encoder signal conditioning circuit 4 for amplifying and filtering the absolute position signal and relative position signal of the servo motor 5 rotation detected by the hybrid photoelectric encoder 6, the input terminal of the photoelectric encoder signal conditioning circuit 4 is connected to the hybrid The output terminal of photoelectric encoder 6 is connected, and the output terminal of described microprocessor 1 is connected with the three-phase power driver 3 that is used to drive the servomotor 5 that hybrid photoelectric encoder is housed, and described servomotor 5 and three-phase power driver 3 output connections.

[0035] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com