Cassia flavor cigarette paper essence and preparation method and application

A technology of cigarette paper and paper flavor, applied in the fields of application, essential oil/fragrance, tobacco, etc., to achieve the effect of improving quality, compensating for the loss of aroma, and improving the overall sensory characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of cinnamon flavor cigarette paper essence, its specific preparation method is:

[0022] Weigh the following raw materials in parts by weight: 20 parts of cinnamyl acetate, 5 parts of cinnamic acid, 90 parts of benzyl alcohol, 800 parts of cinnamaldehyde, 2 parts of cuminaldehyde with a mass concentration of 10%, and salicylaldehyde with a mass concentration of 10%. 2 parts, 4 parts of 3-hydroxy-2-butanone with a mass concentration of 1%, 4 parts of 2,3-pentanedione with a mass concentration of 1%, 10 parts of clove oil, and 63 parts of alcohol with a volume concentration of 95%; Mix and stir the above-mentioned raw materials evenly to prepare cinnamon-flavored cigarette paper essence A.

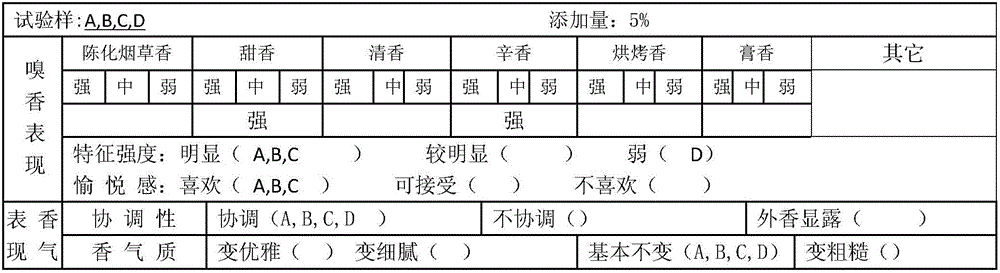

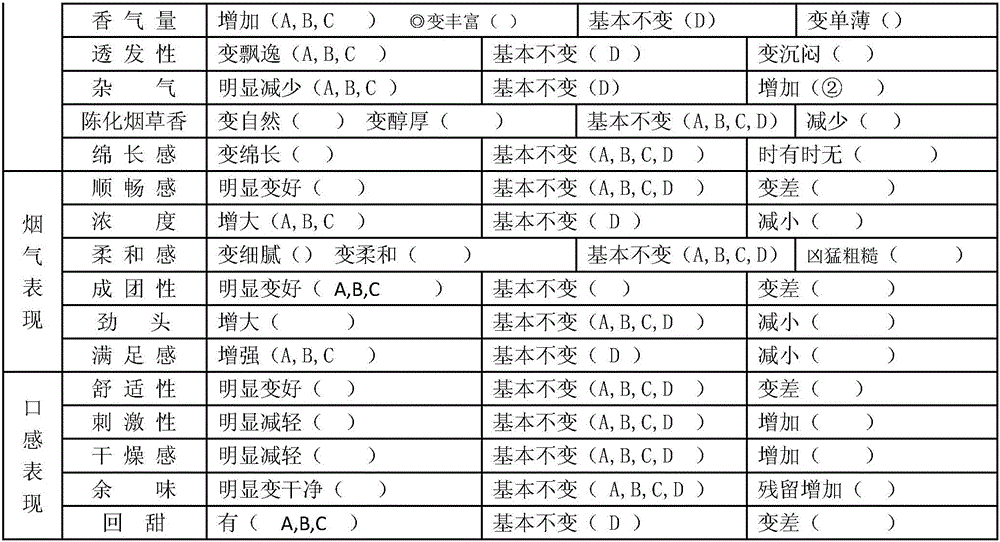

[0023] Add the cinnamon-flavored cigarette paper essence A prepared in Example 1 into the coating solution during the cigarette paper forming process, and stir evenly, and the added amount is 5% of the total weight of the coating solution; then add the cinnamon-fl...

Embodiment 2

[0024] Embodiment 2, a kind of cinnamon flavor cigarette paper essence, its specific preparation method is:

[0025] Weigh the following raw materials in parts by weight: 25 parts of cinnamyl acetate, 10 parts of cinnamic acid, 100 parts of benzyl alcohol, 750 parts of cinnamaldehyde, 3 parts of cuminaldehyde with a mass concentration of 10%, and salicylic acid with a mass concentration of 10%. 1.5 parts of aldehydes, 5 parts of 3-hydroxy-2-butanone with a mass concentration of 1%, 5 parts of 2,3-pentanedione with a mass concentration of 1%, 30 parts of clove oil, and 80.5 parts of alcohol with a volume concentration of 95%; The raw materials are mixed and stirred evenly, and the cinnamon-flavored cigarette paper essence B is prepared.

[0026] Add the cinnamon-flavored cigarette paper essence B prepared in Example 2 into the coating liquid during the cigarette paper forming process, and stir evenly, and the added amount is 5% of the total weight of the coating liquid; then ad...

Embodiment 3

[0027] Embodiment 3, a kind of cinnamon flavor cigarette paper essence, its specific preparation method is:

[0028] Weigh the following raw materials in parts by weight: 30 parts of cinnamyl acetate, 10 parts of cinnamic acid, 95 parts of benzyl alcohol, 700 parts of cinnamaldehyde, 4 parts of cuminaldehyde with a mass concentration of 10%, and salicylic acid with a mass concentration of 10%. 1 part of aldehyde, 6 parts of 3-hydroxyl-2-butanone of 1% in mass concentration, 6 parts of 2,3-pentanedione of 1% in mass concentration, 20 parts of clove oil, 128 parts of 95% (volume ratio) alcohol; The above-mentioned raw materials are mixed and stirred evenly, and the cinnamon-flavored cigarette paper essence C is prepared.

[0029] Add the cinnamon-flavored cigarette paper essence C prepared in Example 3 into the coating liquid during the cigarette paper forming process, and stir evenly, and the added amount is 5% of the total weight of the coating liquid; then add the cinnamon-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com