Latex pillow with plastic shape and preparation method thereof

A latex pillow and natural latex technology, applied in pillows, bedspreads, household appliances and other directions, can solve the problems of adaptable fit of objects that cannot be leaned against, poor efficacy, poor plasticity, etc., to inhibit the breeding of mites, and easy to operate. And convenient, simple processing and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

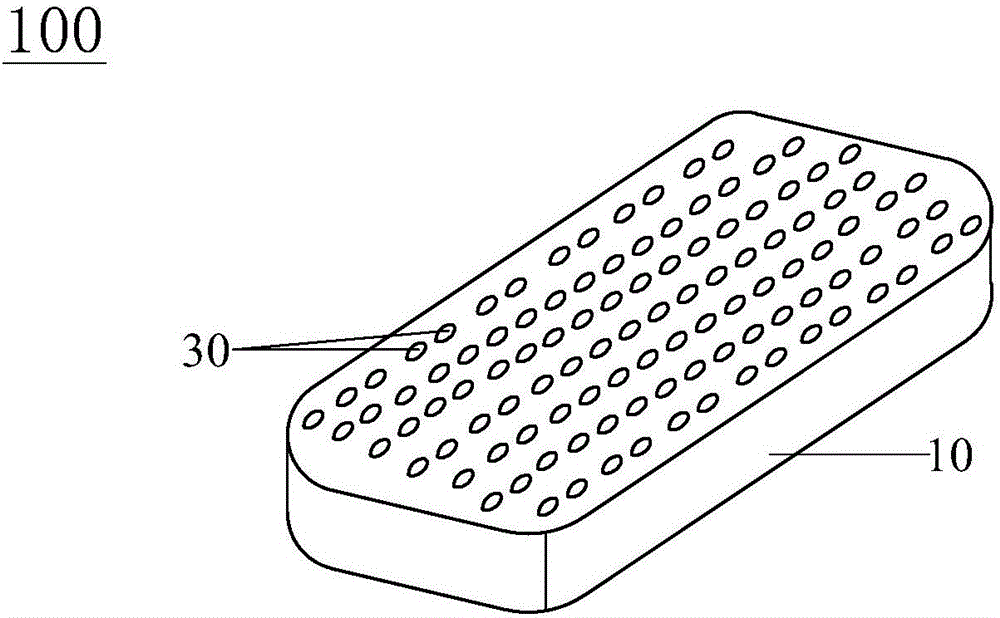

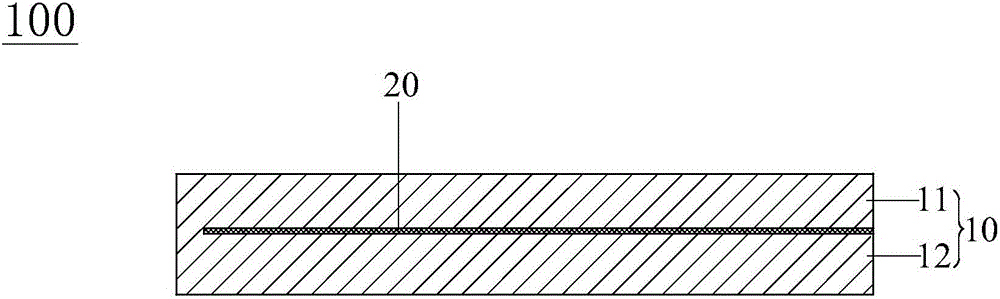

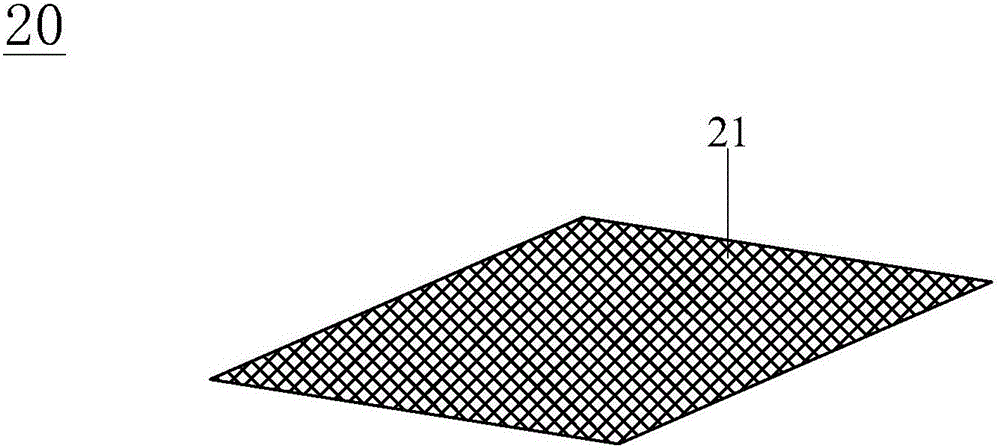

[0039] see Figure 1 to Figure 8 , the present invention discloses a latex pillow 100 with a plastic shape, which includes a latex pillow core 10 made of natural latex foam. The latex pillow core 10 itself can inhibit the breeding of mites, is easy to clean, and is safe and environmentally friendly to use. Preferably, the moldable latex pillow 100 also includes a pillowcase (not shown) that is sleeved on the outside of the latex pillow core 10 and matches the shape of the latex pillow core 10. The pillowcase is made of high-grade jacquard velvet or crystal velvet. As a result, while protecting the latex pillow core 10, it also improves the comfort of use and is convenient for assembly and cleaning. The moldable latex pillow 100 of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com