Demineralized water tank for high-temperature condensate water and manufacturing method thereof

A technology of high temperature condensation and manufacturing method, applied in the direction of manufacturing tools, edge parts of workpieces, welding/welding/cutting items, etc., can solve problems such as increasing costs and increasing equipment costs, and achieve the effect of avoiding scars and peeling, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the accompanying drawings.

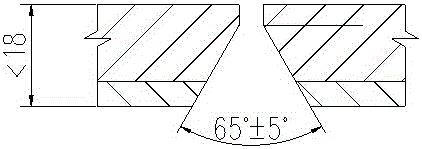

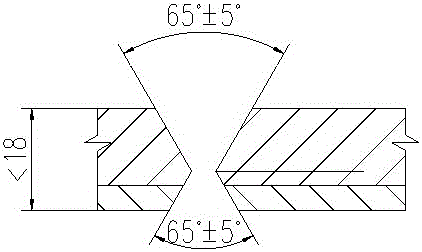

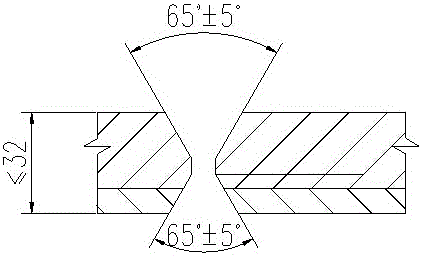

[0046] A specific embodiment of the present invention is a desalinated water tank for high-temperature condensed water, including a water tank main body. The main body of the water tank is a composite steel plate lap joint, and the seam is designed with a special structure. According to the thickness of the composite steel plate, different The method of cutting and groove processing is carried out in the order of welding base layer, cladding root cleaning, welding transition layer, and welding cladding layer. Both the welding transition layer and the welding cladding layer are welded by manual arc welding. The composite steel plate of the water tank Composite steel and stainless steel, the outer layer is a carbon steel base layer, which is used as the main support structure of the water tank, and the inner layer of the composite steel plate of the water tank main body is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com