Laser continuous preparation method for nano graphite particles under effect of limiting layer

A technology of nano-graphite and graphite particles, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of high cost and achieve the effect of low cost, low density and significant economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

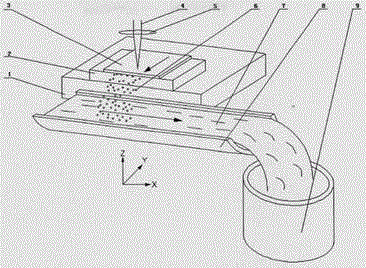

[0033] The schematic diagram of the experimental device of the present invention is as figure 1 As shown, a laser continuous preparation method of nano-graphite particles under the action of a confinement layer, specifically comprises the following steps:

[0034] (1) First place the graphite sheet target 2 on the top of the workbench 1;

[0035] (2) Then change the glass confinement layer 3 above the graphite sheet target material 2, and ensure that the two are closely bonded together;

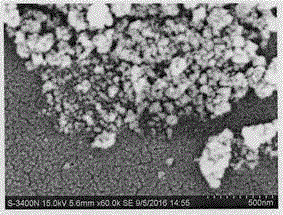

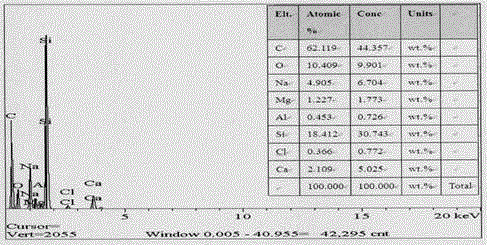

[0036] (3) Set the 4 parameters of the pulsed laser, among which, the power is 18W, the repetition frequency is 25kHz, the pulse width is 100ns, the number of scans is 2000 times, and the scanning method is galvanometer filling scanning. Focusing the pulse laser 4 through the lens 5 on the interface between the graphite sheet target 2 and the glass confinement layer 3, scanning, filling and ablation the graphite sheet target 2, so that the surface material of the graphite sheet target 2 is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com