Denitrification treatment method for livestock and poultry breeding wastewater

A technology for livestock and poultry breeding wastewater and a treatment method, which is applied in the field of sewage treatment, can solve the problems of difficulty in treatment, increased treatment costs, and high organic content, and achieves the effects of reducing oxygen demand and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

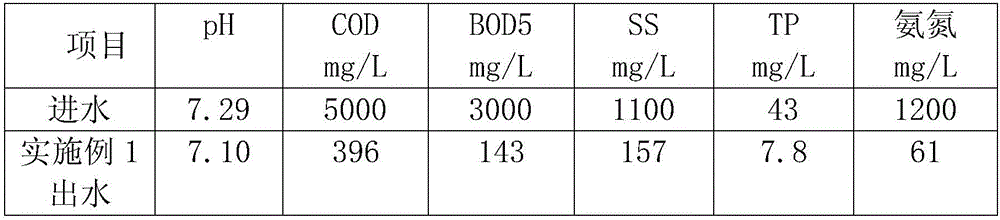

Embodiment 1

[0020] After being pretreated by coarse screen, aerated grit chamber and anaerobic tank, livestock and poultry breeding wastewater is treated in turn through primary sedimentation tank, biological tank and secondary sedimentation tank. The biological tank includes aerobic section and anoxic section; The effluent from the primary sedimentation tank flows into the aerobic section and the anoxic section at the same time through the distribution well, 60% is distributed to the anoxic section, and the remaining 40% is distributed to the aerobic section; the effluent from the aerobic section enters the anoxic section for treatment, and the anoxic section Part of the effluent is returned to the aerobic section with a reflux rate of 40%. The rest of the effluent enters the secondary settling tank for sedimentation and separation, and the effluent is discharged through the discharge port; diatomaceous earth and grape seed tannin are added to the aerobic section. The ratio is 1:0.5; the ...

Embodiment 2

[0024] After being pretreated by coarse screen, aerated grit chamber and anaerobic tank, livestock and poultry breeding wastewater is treated in turn through primary sedimentation tank, biological tank and secondary sedimentation tank. The biological tank includes aerobic section and anoxic section; The effluent from the primary sedimentation tank flows into the aerobic section and the anoxic section at the same time through the distribution well, 80% is distributed to the anoxic section, and the remaining 20% is distributed to the aerobic section; the effluent from the aerobic section enters the anoxic section for treatment, and the anoxic section Part of the effluent is returned to the aerobic section with a reflux rate of 50%. The remaining effluent enters the secondary settling tank for sedimentation and separation, and the effluent is discharged through the discharge port; diatomaceous earth and grape seed tannin are added to the aerobic section. The ratio is 3:1.8; the ...

Embodiment 3

[0026] After being pretreated by coarse screen, aerated grit chamber and anaerobic tank, livestock and poultry breeding wastewater is treated in turn through primary sedimentation tank, biological tank and secondary sedimentation tank. The biological tank includes aerobic section and anoxic section; The effluent from the primary sedimentation tank flows into the aerobic section and the anoxic section at the same time through the distribution well, 70% is distributed to the anoxic section, and the remaining 30% is distributed to the aerobic section; the effluent from the aerobic section enters the anoxic section for treatment, and the anoxic section Part of the effluent flows back to the aerobic section with a reflux rate of 45%. The remaining effluent enters the secondary settling tank for sedimentation and separation, and the effluent is discharged through the discharge port; diatomaceous earth and grape seed tannin are added to the aerobic section. The ratio is 1:1.8; the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com