Anti-hepatitis C Daclatasvir synthesis method

A technology of anti-hepatitis C daclatasvir and synthetic method, which is applied in the field of synthesis of anti-hepatitis C daclatasvir, can solve the problems of complex synthetic route and high cost of production raw materials, and achieve simple reaction, low cost of production raw materials, and step-by-step synthetic route little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

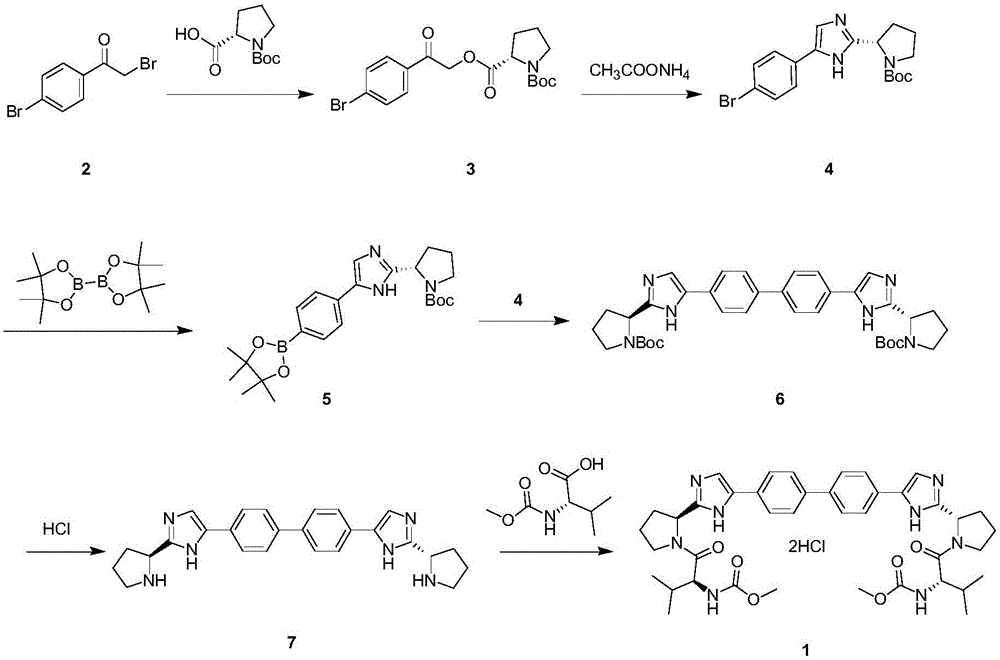

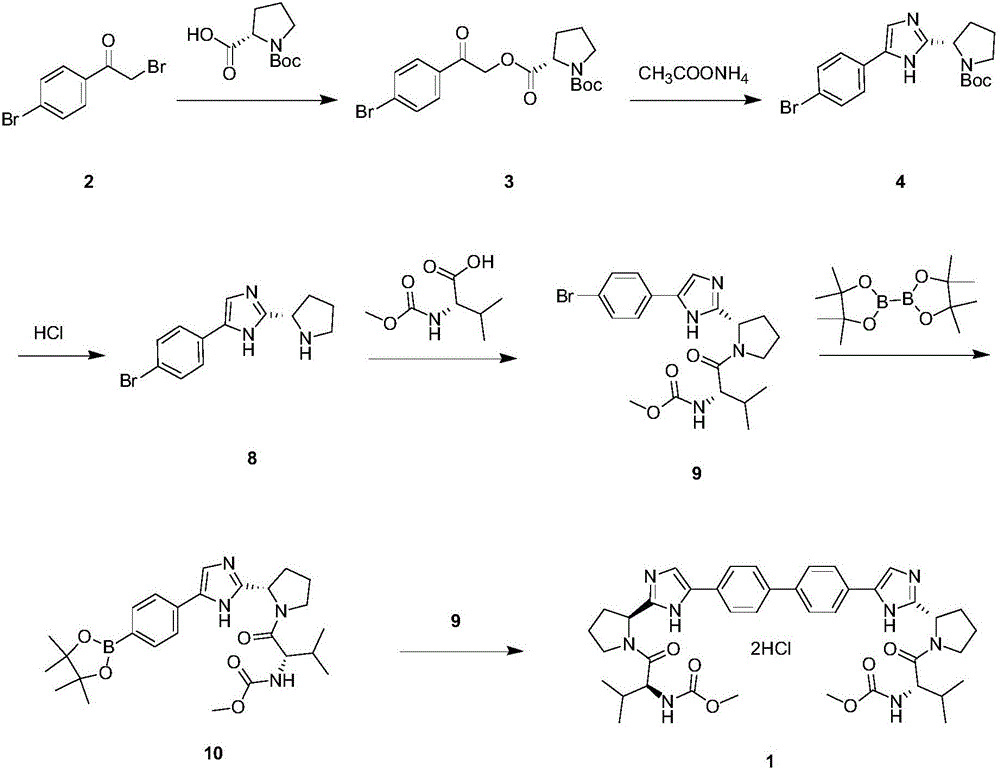

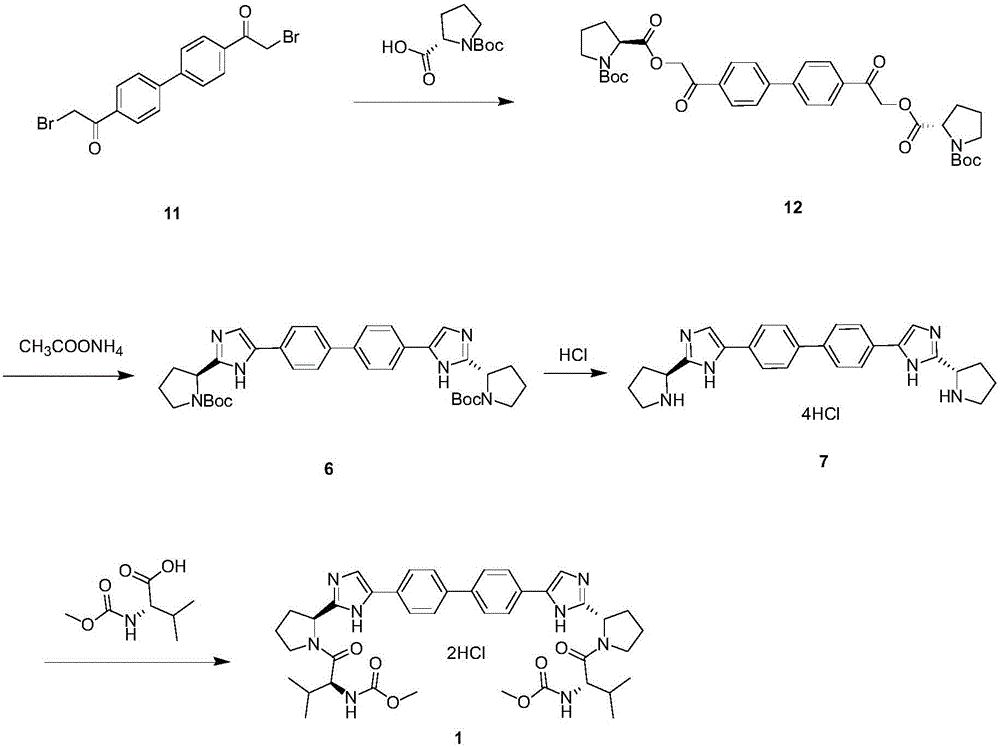

[0025] Such as Figure 4 Shown, a kind of synthetic method of anti-hepatitis C daclatasvir, this synthetic method comprises the following steps:

[0026] (1) Using 4,4'-bis(2-chloroacetyl)biphenyl to condense with Boc-L-proline to generate ester;

[0027] (2) take above-mentioned ester and ammonium acetate ring closure, obtain imidazole;

[0028] (3) De-Boc the imidazole to obtain the hydrochloride;

[0029] (4) Take the hydrochloride and carry out Moc-L-valine condensation to obtain daclatasvir.

specific Embodiment approach 1

[0031] (1) Synthesis of esters

[0032] Stage a. Put 4,4'-bis(2-chloroacetyl)biphenyl (7.5g, 24.4mmol), Boc-L-proline (10.5g, 48.8mmol) and acetonitrile (70mL) into the reaction flask , add diisopropylethylamine DIPEA (6.5g, 50mmol);

[0033] Stage b. Heat up to 25°C (temperature range is 25-82°C), stir for 36 hours, the reaction is completed, the reaction solution is concentrated under reduced pressure, and replaced with toluene solution (140mL);

[0034] Stage c, washing twice with saturated sodium chloride (70 mL), concentrating toluene to obtain an oily foamy solid, namely the desired ester (15.6 g, yield 96.3%).

[0035] (2) Synthesis of imidazole

[0036] Add ester (15.6g, 23.5mmol) and 95mL toluene to the reaction flask, add ammonium acetate (30g, 389mmol), heat up to 95°C (temperature range is 95-100°C), and react for 15 hours;

[0037] Cool down to 60°C, slowly add saturated aqueous sodium bicarbonate solution, adjust the pH to 7 (PH range 7-8);

[0038] Layer at ...

specific Embodiment approach 2

[0049] (1) Synthesis of esters

[0050] Stage a. Put 4,4'-bis(2-chloroacetyl)biphenyl (7.5g, 24.4mmol), Boc-L-proline (10.5g, 48.8mmol) and acetonitrile (70mL) into the reaction flask , add diisopropylethylamine DIPEA (6.5g, 50mmol);

[0051] Stage b: heat up to 65°C (temperature range is 25-82°C), stir for 8 hours, the reaction is completed, the reaction solution is concentrated under reduced pressure, and replaced with toluene solution (140mL);

[0052] Stage c, washing twice with saturated sodium chloride (70 mL), concentrating toluene to obtain an oily foamy solid, namely the desired ester (15.6 g, yield 96.3%).

[0053] (2) Synthesis of imidazole

[0054] Add ester (15.6g, 23.5mmol) and 95mL toluene to the reaction flask, add ammonium acetate (30g, 389mmol), heat up to 97°C (temperature range is 95-100°C), and react for 15 hours;

[0055] Cool down to 60°C, slowly add saturated aqueous sodium bicarbonate solution, and adjust the pH to 7.3 (pH range 7-8);

[0056] Laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com