Erasable water-based white board marker ink and preparation method thereof

A pen-ink and water-based technology, applied in the field of ink, can solve the problems of strong smell of whiteboard pens and inconvenient wiping, etc., and achieve the effect of clear writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

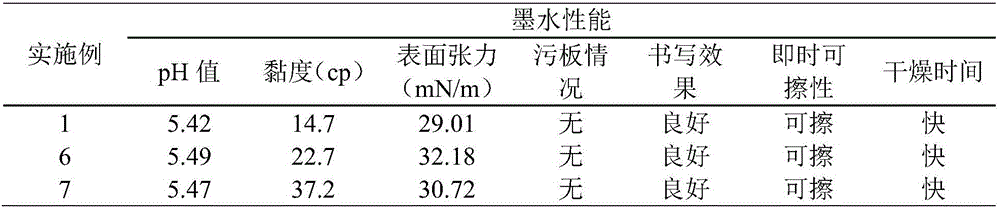

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned erasable water-based whiteboard pen ink is specifically implemented according to the following steps:

[0030] Step 1, weigh 4-6% of the coloring agent, 1.5-4% of the film-forming agent, 75-85% of the solvent, and 9.5-16% of the auxiliary agent according to the mass percentage, and the sum of the mass percentages of the above components is 100%. The agent is one or more of surfactant, humectant and lubricant, ethanol;

[0031] Step 2, adding the film-forming agent into the solvent, and stirring until completely dissolved under the condition that the temperature of the water bath is 80-85° C., to obtain System I;

[0032] Step 3, adding the lubricant into ethanol and stirring evenly to obtain System II;

[0033] Step 4: After mixing system I and system II, add surfactant, colorant and moisturizer respectively, and stir for 6-7 hours to obtain erasable water-based whiteboard pen ink.

[0034] The invention provides a green, ...

Embodiment 1

[0036] Add 1.5g of polyvinyl alcohol 1788 and 85g of deionized water into a round-bottomed flask, heat and stir in a water bath to dissolve completely at 80°C to obtain system I.

[0037] Add 0.2 g of zinc stearate into 5 g of warm ethanol and stir evenly to obtain System II.

[0038] Add system I and system II into a beaker, and then add 3.5g of surfactant OP-10, 4.0g of carbon black, and 0.6g of glycerin. The beaker was placed on a magnetic stirrer and stirred for 6 hours to obtain ink samples.

Embodiment 2

[0040] Add 4.0g of polyvinyl alcohol 1788 and 75g of deionized water into a round-bottomed flask, heat and stir in a water bath to dissolve completely at 80°C to obtain System I.

[0041] The butyl stearate of 1.3g is joined in the ethanol of 8g and stirs evenly. System II was prepared.

[0042] Add system I and system II into a beaker, and then add 5.5 g of surfactant sodium dodecylbenzenesulfonate, 5.0 g of carbon black, and 1.2 g of xylitol. The beaker was placed on a magnetic stirrer and stirred for 6 hours to obtain ink samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com