Preparation method of graphene heat conduction double-sided adhesive tape

A heat-conducting double-sided adhesive and graphene technology, applied in the direction of heat exchange materials, chemical instruments and methods, adhesives, etc., to achieve the effect of minimum addition, improve thermal conductivity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

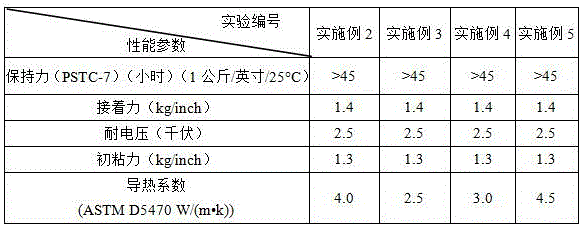

Examples

Embodiment 1

[0037] A preparation method of graphene thermally conductive double-sided adhesive, comprising the steps of:

[0038] (1) Stir and mix the thermally conductive filler and graphene powder, so that the graphene covers the thermally conductive filler, then add the dispersion liquid composed of silane coupling agent and ethanol, stir and mix, and obtain a composite thermally conductive filler after mixing.

[0039] The specific process of this step is that the specific process of the above step (1) is: firstly add the thermally conductive filler and graphene powder into a kneader or a high-speed stirrer, stir and mix at a high speed at room temperature for 10min-1h, so that the graphene Coat the thermally conductive filler, then add the silane coupling agent to ethanol to form a silane coupling agent dispersion, and add the silane coupling agent dispersion to the kneader or high-speed stirring in the form of spray during the high-speed stirring process In the container, after the ...

Embodiment 2

[0049] A preparation method of graphene thermally conductive double-sided adhesive, comprising the steps of:

[0050] (1) First add the thermally conductive filler and graphene powder into the kneader or high-speed mixer in proportion, and stir and mix at high speed for 10 minutes at room temperature to make the graphene cover the thermally conductive filler; then add the silane coupling agent to the water content Prepare the silane coupling agent dispersion with a mass percent concentration of 5% in less than 1% ethanol, and add the silane coupling agent dispersion to the kneader or high-speed agitator in the form of spray during high-speed stirring After the addition is completed, continue to stir at a high speed for 30 minutes, take it out, and obtain the processed composite thermally conductive filler. Among them, the mass fraction of graphene in the composite thermally conductive filler is 1%, and the mass fraction of the silane coupling agent in the composite thermally c...

Embodiment 3

[0055] A preparation method of graphene thermally conductive double-sided adhesive, comprising the steps of:

[0056] (1) First, add the thermally conductive filler and graphene powder into the kneader or high-speed mixer in proportion, and stir and mix at high speed for 1 hour at room temperature to make the graphene cover the thermally conductive filler; then add the silane coupling agent to the water content Prepare a silane coupling agent dispersion with a mass percent concentration of 10% in ethanol less than 1%, and add the silane coupling agent dispersion to the kneader or high-speed agitator in the form of spray during high-speed stirring After the addition is completed, continue to stir at a high speed for 2 hours, take it out, and obtain the processed composite thermally conductive filler. Among them, the mass fraction of graphene in the composite thermally conductive filler is 5%, and the mass fraction of the silane coupling agent in the composite thermally conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com