Vertical type three-dimensional polyester short fiber relaxation heat-setting machine

A technology of heat setting machine and short fiber, which is applied to the processing of textile material carriers, equipment configuration for processing textile materials, and processing of textile materials, etc. It can solve the problems of high energy consumption, easy loosening of chain plate screws, and reduced product quality. Achieve the effects of convenient process adjustment, less exhaust air volume and less heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

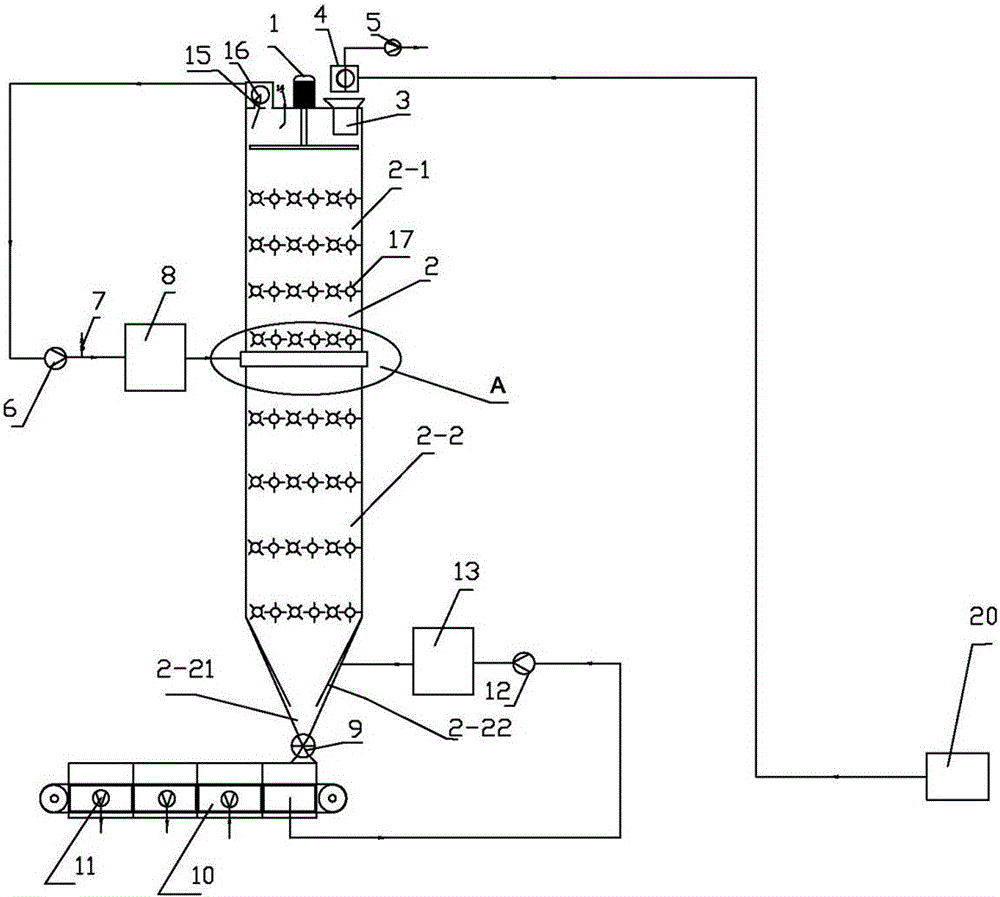

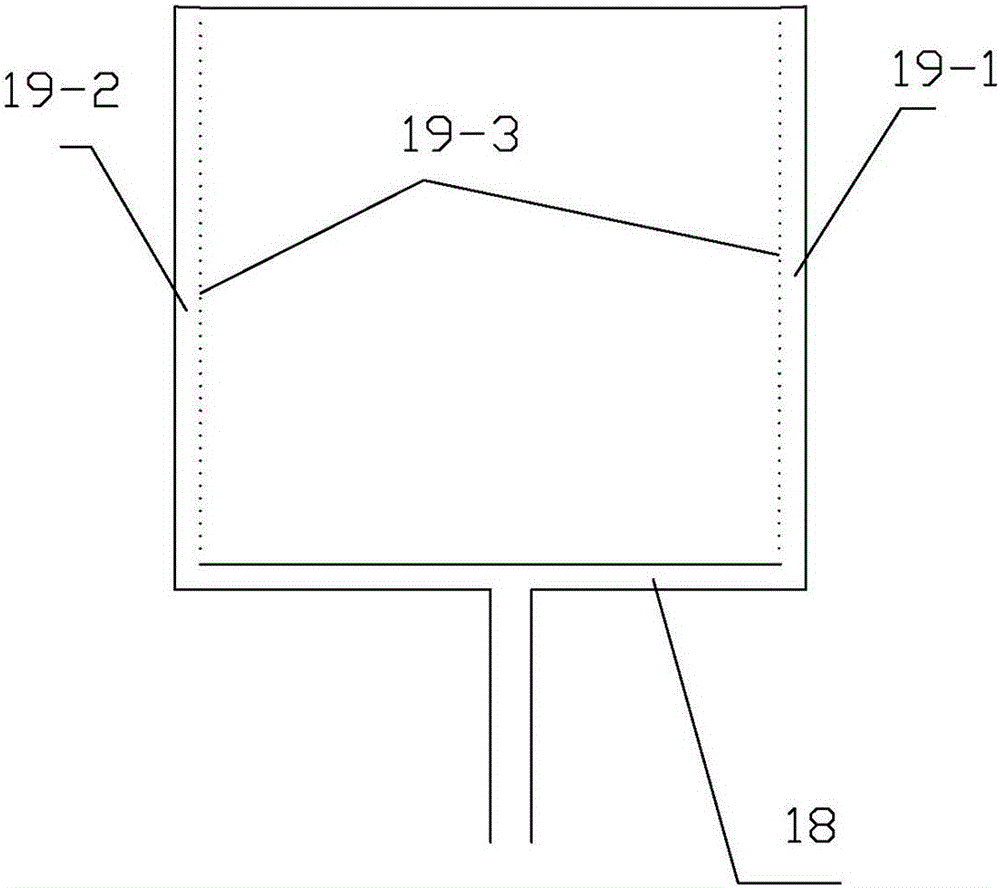

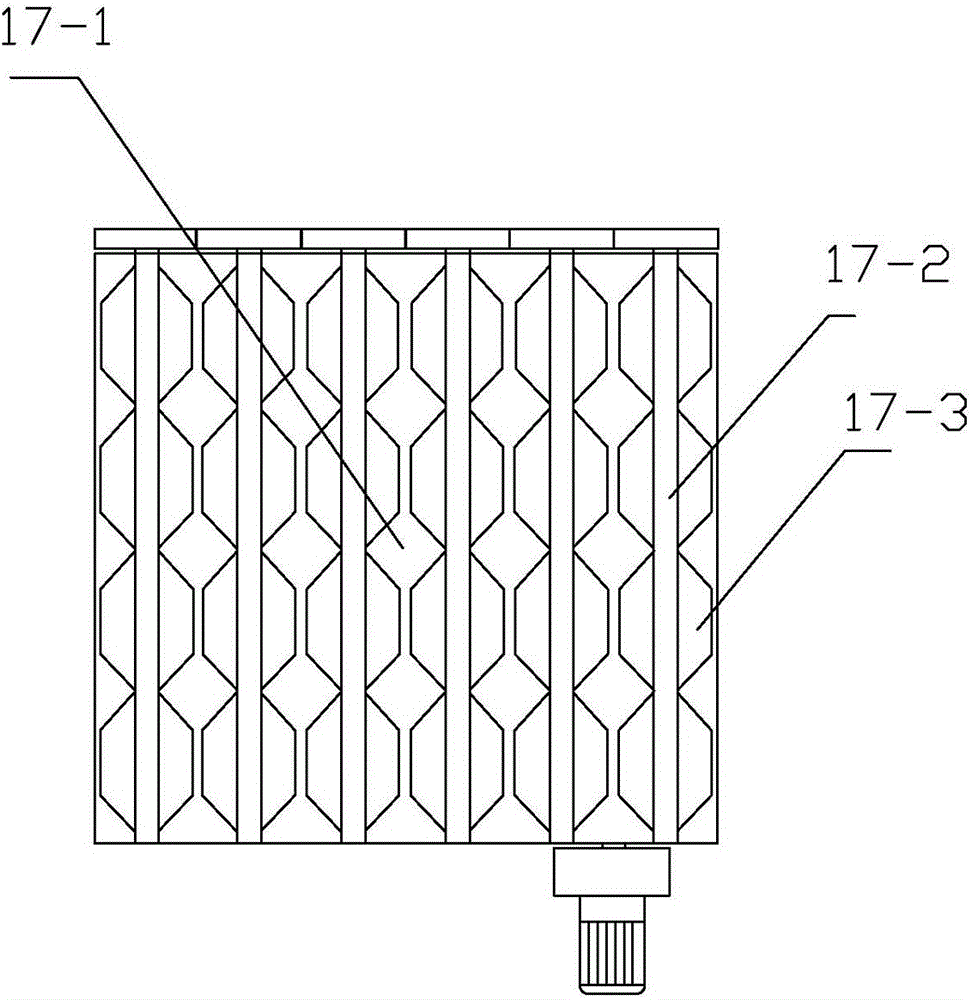

[0019] like figure 1 , figure 2 , image 3 As shown, the shape of the vertical polyester three-dimensional short fiber relaxation heat setting machine is a vertical tower 2, the upper section is the dehumidification section 2-1, and the lower section is the shaping section 2-2; Machine 1, the top is also connected with a silk inlet 3, a cotton suction machine 4 and a centrifugal fan 5 are arranged above the silk inlet, and a high-pressure fan 6, a wet air discharge valve 7, a heating 8; an air lock valve 9 is provided at the outlet of the bottom of the shaping section, a cooling chain plate 10 is provided under the bottom of the shaping section, and three cooling fans 11 are arranged on the cooling chain plate, between the first cooling section of the cooling chain plate and the lower part of the shaping section A high-pressure blower 12 and a heater 13 are arranged in turn, so that the hot air from the outlet is sent back to the shaping section to recycle heat energy. Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com