Clean water deconcentration system for mechanically mined brine

A brine and clear water technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of being unable to put into production, unable to realize continuous operation, limited operability, etc., and achieve the extension of continuous production time , Conducive to continuous production and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

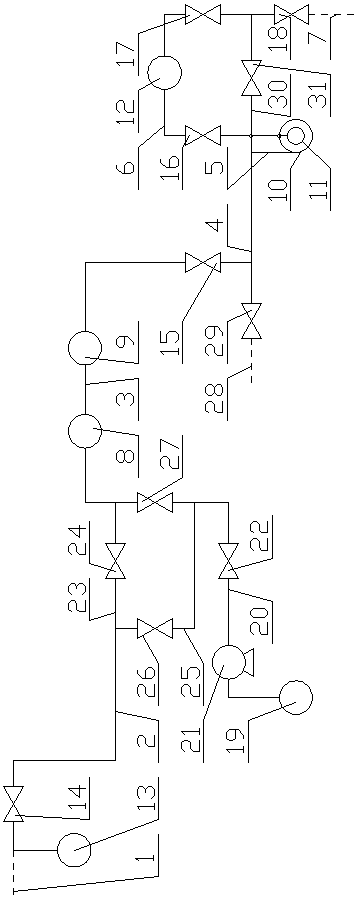

[0018] Such as figure 1 As shown, the present invention includes a salt well A13 and a salt well B10. A central pipe 11 is arranged inside the salt well B10. The bottom of the central pipe 11 communicates with the lower part of the salt well B10. The salt well B10 communicates with a central pipe B5. An electric submersible pump is arranged inside the pipe 11, and the discharge end of the electric submersible pump communicates with the brine outlet pipe 7 through the pipe D6; it also includes the water injection pipe 1 of the salt well A13, and the water injection pipe 1 communicates with the brine well A13 through the water inlet pipe A. The water injection pipe 1 communicates with the salt well B10 through the pipeline A2, the pipeline B3 and the pipeline C4 before the water inlet pipeline A of the salt well A13, and the pipeline C4 communicates with the salt well B10 through the water inlet pipeline B5; the pipeline A2 is communicated with a valve A14, and the pipeline B3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com