Large spiral oil press

An oil press and screw technology, applied in the field of large screw oil press, can solve the problems of unstable operation of the machine, inconvenient installation and maintenance, material blockage and traffic jam, etc., and achieve the effect of long production time, easy maintenance and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further clearly described:

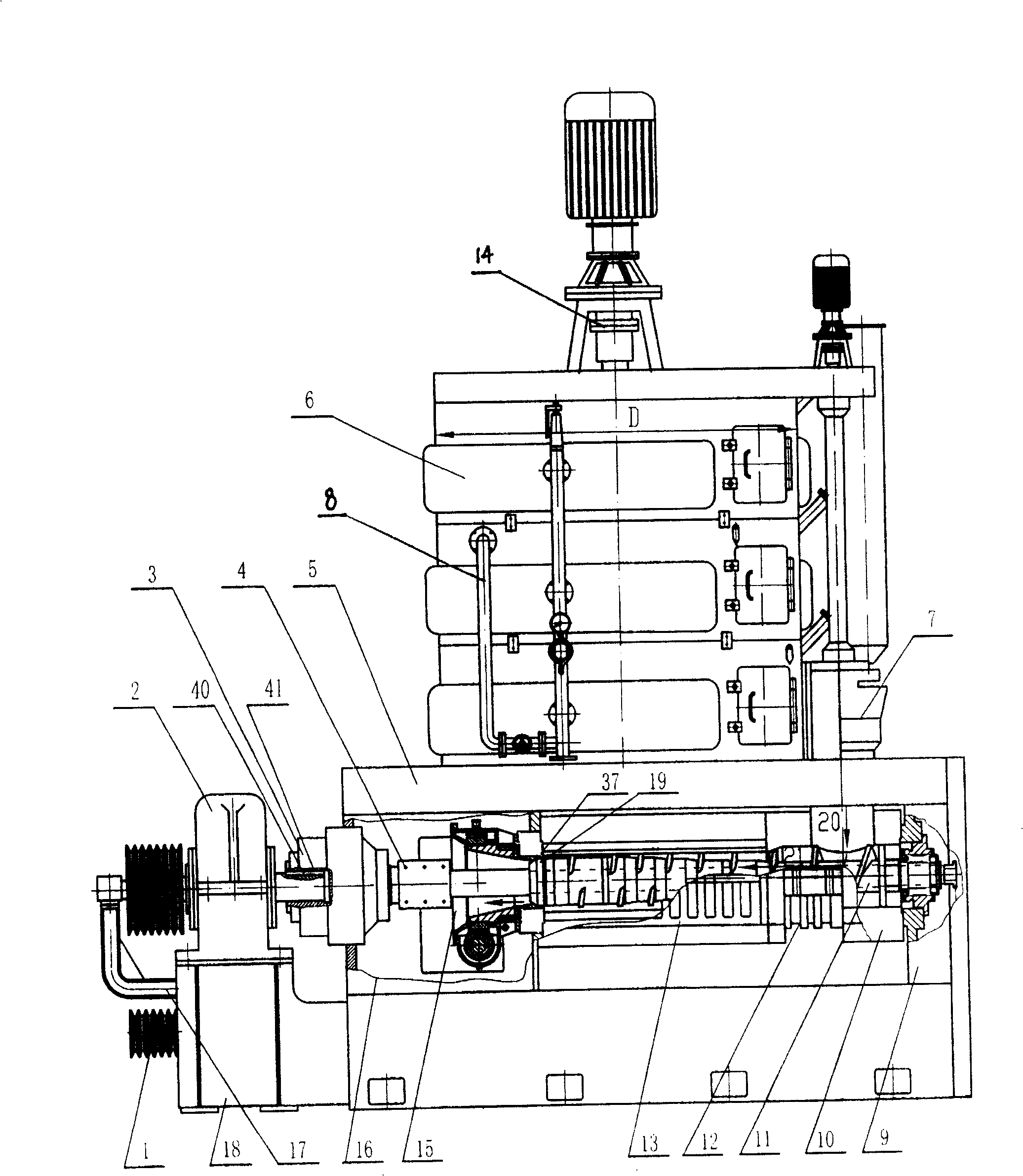

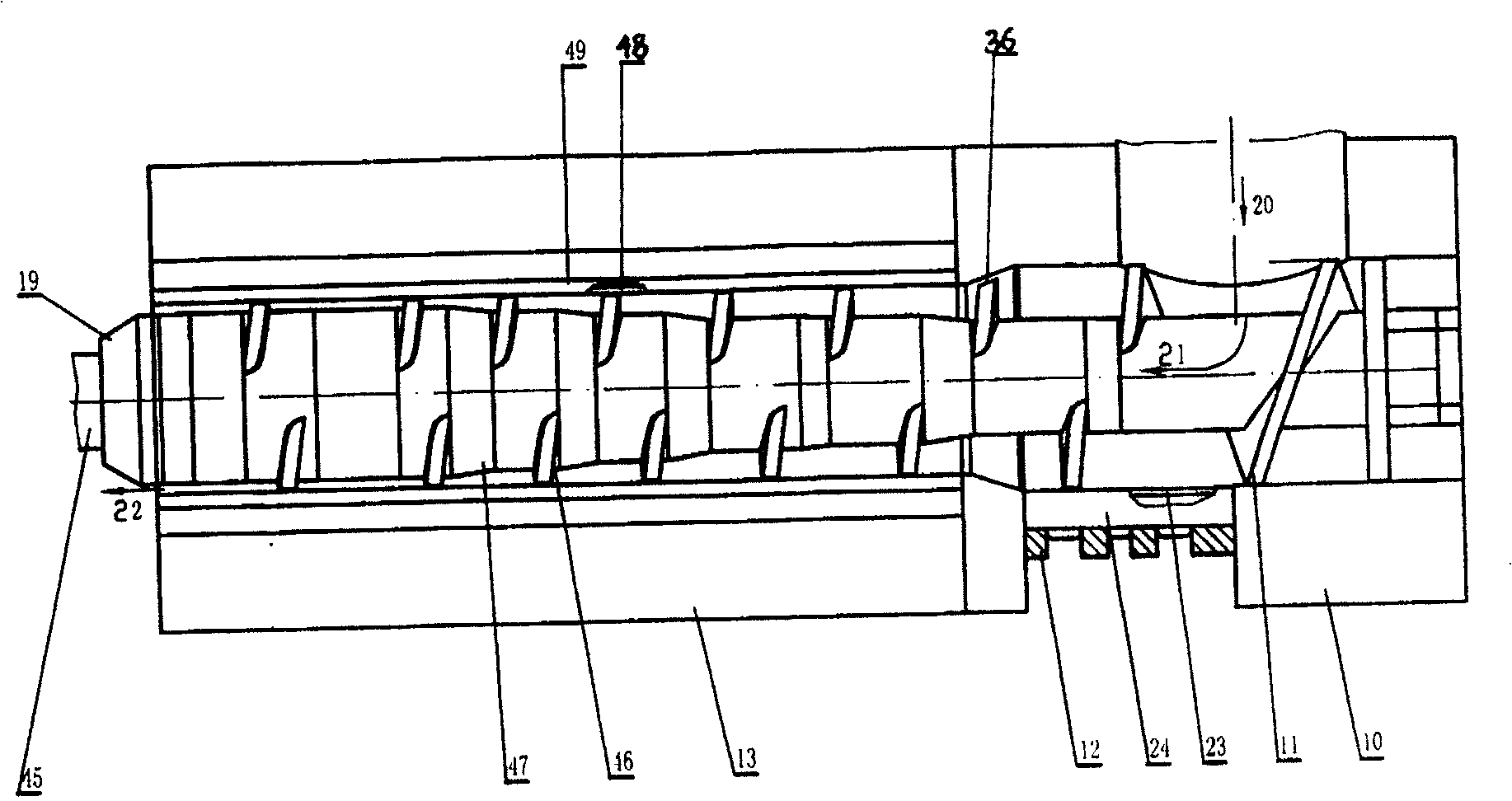

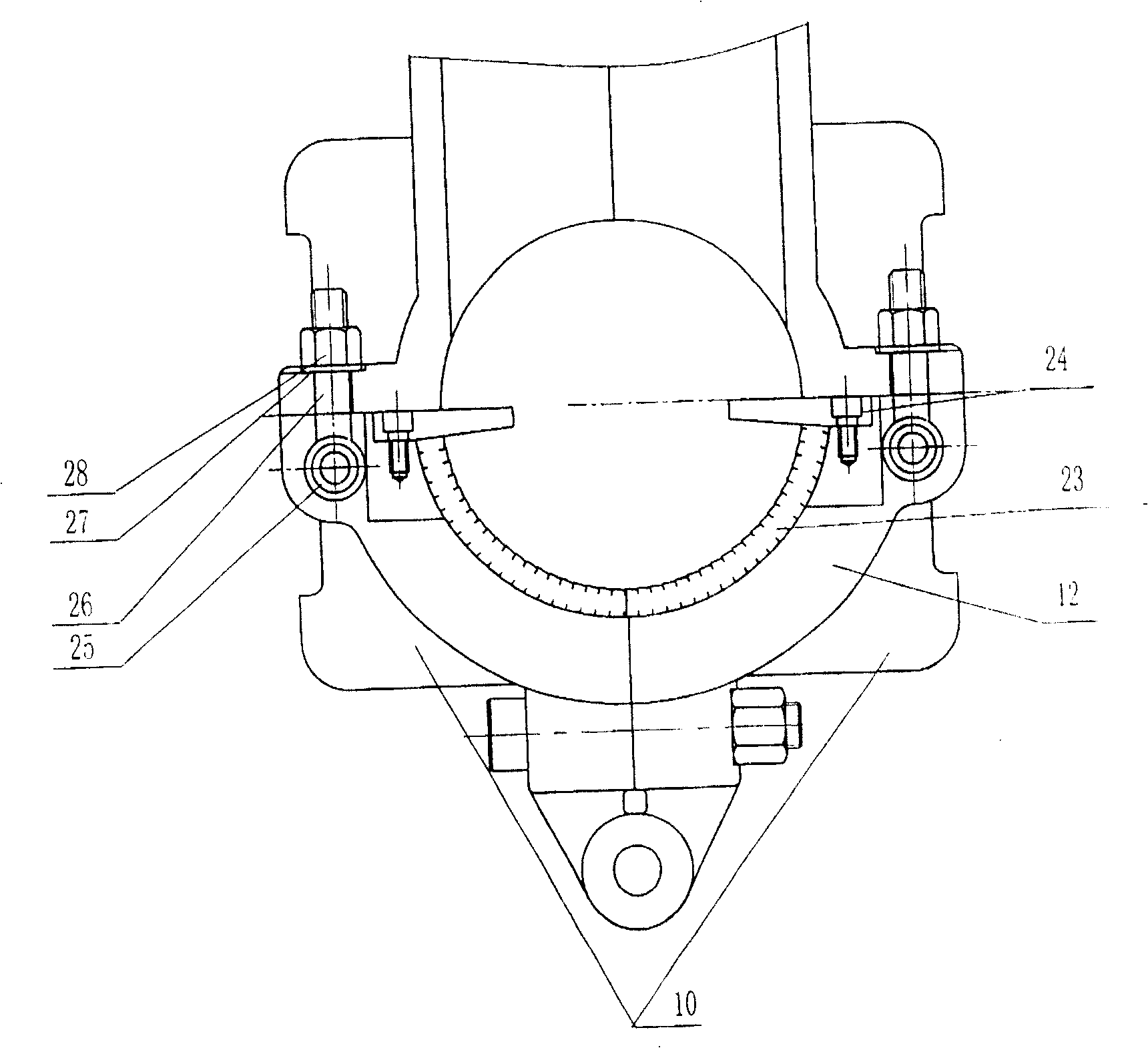

[0015] Such as figure 1 As shown, the utility model comprises a motor pulley 1, a frame 5, a reconciliation steaming wok 6 and a screw oil press mounted on the frame 5, such as figure 2 , image 3 As shown, the squeeze cage shell is connected by bolts to the left and right short squeeze cage shells 10 and the left and right long squeeze cage shells 13, and then connected into a section of the whole squeeze cage shell to be loaded into the middle of the front frame 9 and the box body 16, and the short squeeze cage shell 10 A half-press cage 12 is arranged between the long-press cage 13, and the semicircular bottom of the half-press cage 12 is equipped with a press bar 23 and a scraper 24, and the half-press cage 12 is equipped with a rotating shaft 25, a round eye bolt 26, a 27 nuts and 28 are connected to the left and right short press cage shells, and face the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com