A dpf regeneration system and control method

A regeneration system and DPF technology, which is applied in the electronic control of exhaust treatment devices, machines/engines, mechanical equipment, etc., can solve the problems of inability to regenerate DPF in real time online, low regeneration efficiency, and decreased NTP utilization rate, so as to save energy , Improve the utilization rate, improve the effect of regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

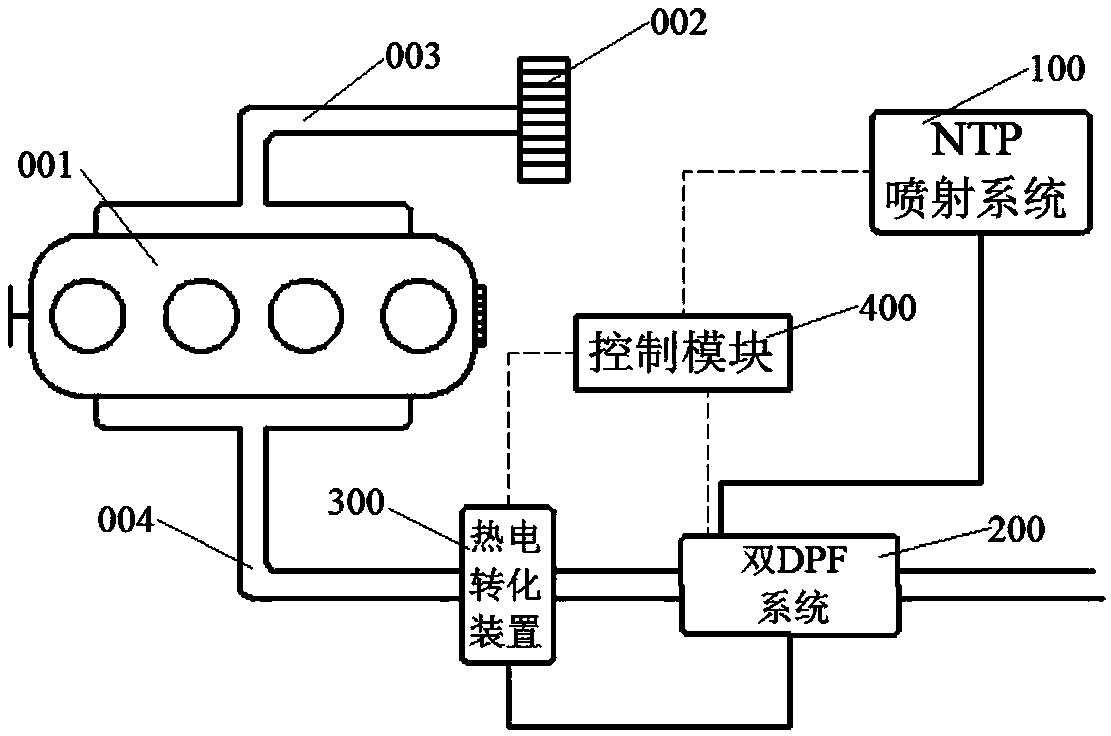

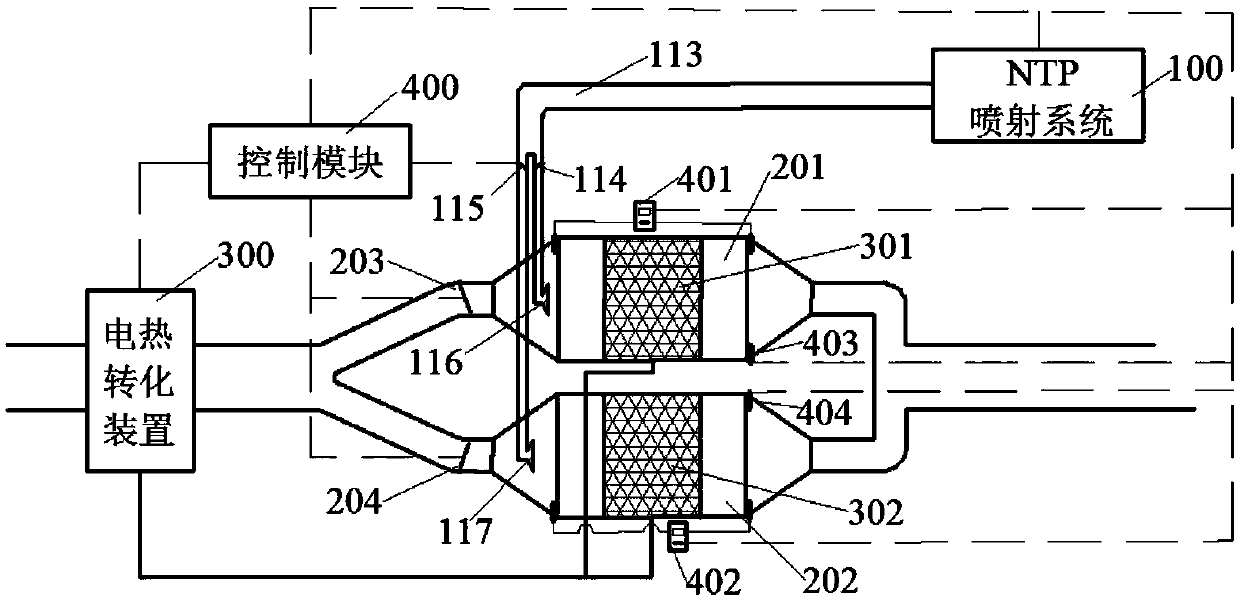

[0046] Such as figure 1 As shown, the DPF regeneration system of the present invention includes an NTP injection system 100, a double DPF system 200, a thermoelectric conversion device 300 and a control module 400, and the thermoelectric conversion device 300 is installed on the exhaust pipe at the front end of the dual DPF system 200 , the NTP injection system 100 , the dual DPF system 200 and the thermoelectric conversion device 300 are all connected to the control module 400 .

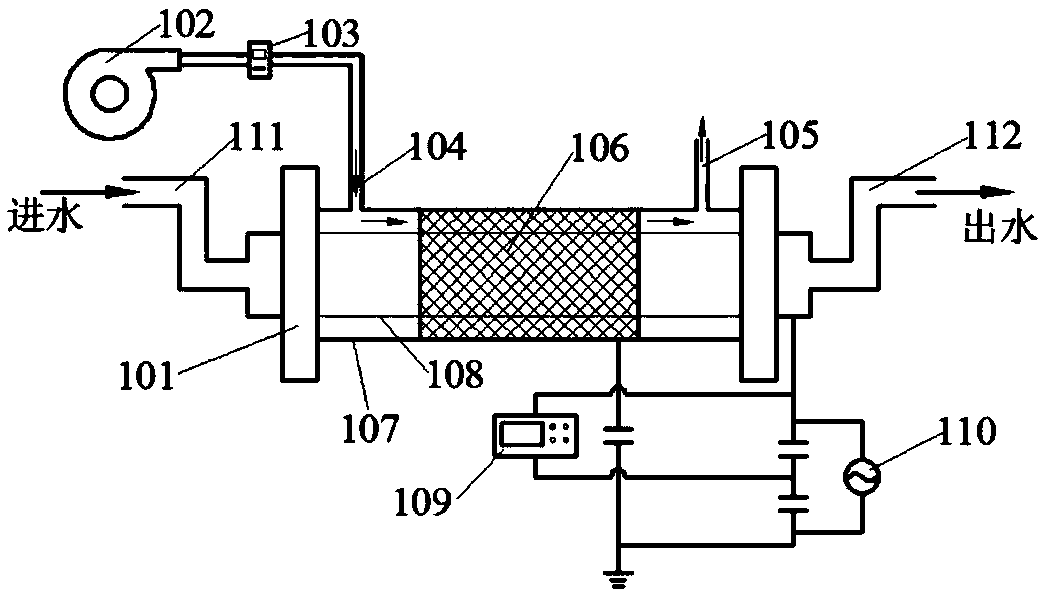

[0047] Such as figure 2 As shown, the NTP injection system 100 includes an NTP generator 101, an air supply fan 102, a mass flow controller 103, an oscilloscope 109, a power supply 110, an injection pipeline 113, and a nozzle. The NTP generator 101 is a dielectric barrier discharge type, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com