Reciprocating piston compressor for energy saving, noise reduction, noise reduction and vibration reduction and method for reducing noise and noise

A technology of reciprocating piston and compressor, used in liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc. problems, to achieve the effect of straightening the frequency response characteristic curve, increasing the cooling capacity of the compressor, and reducing the noise of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

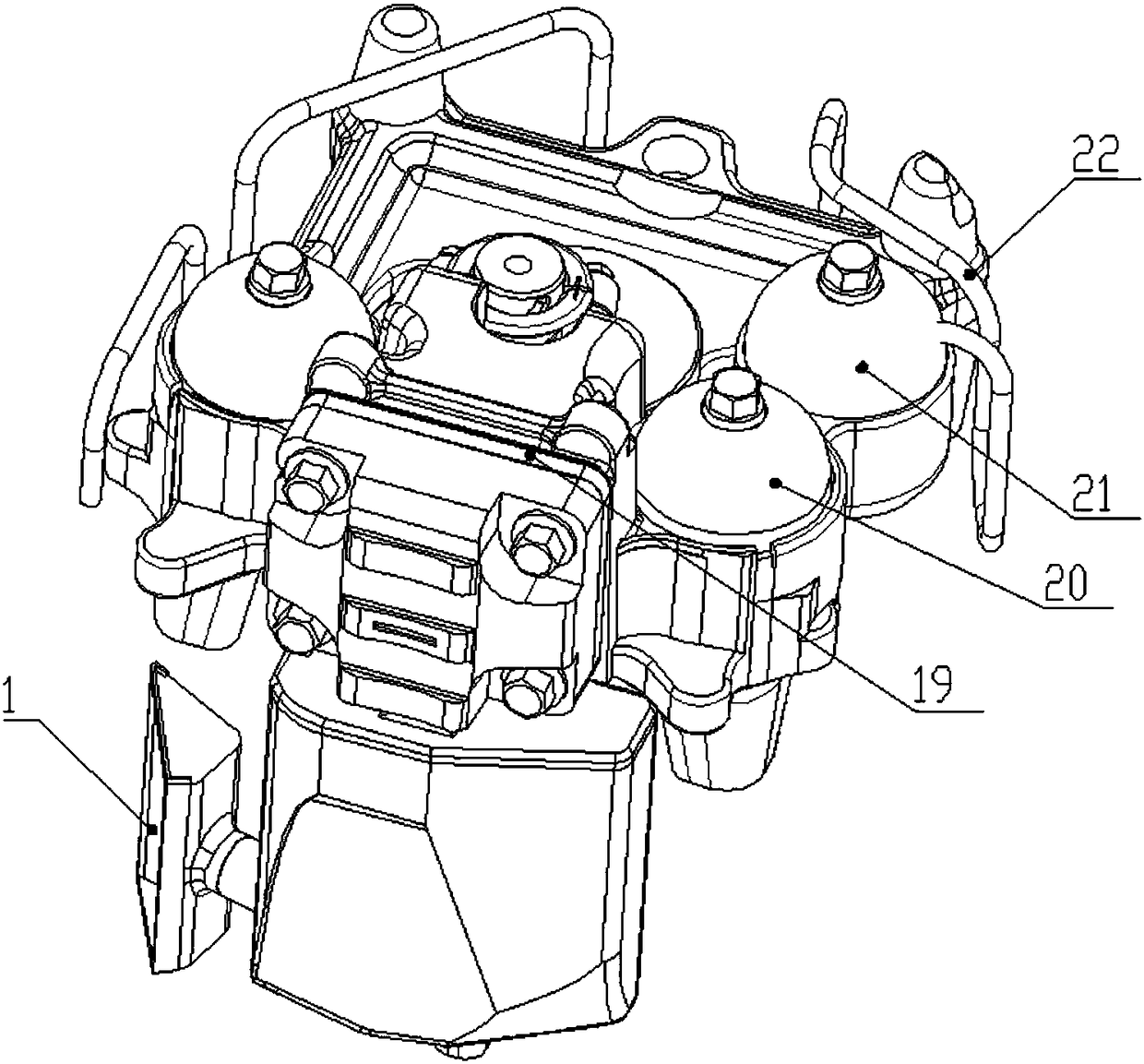

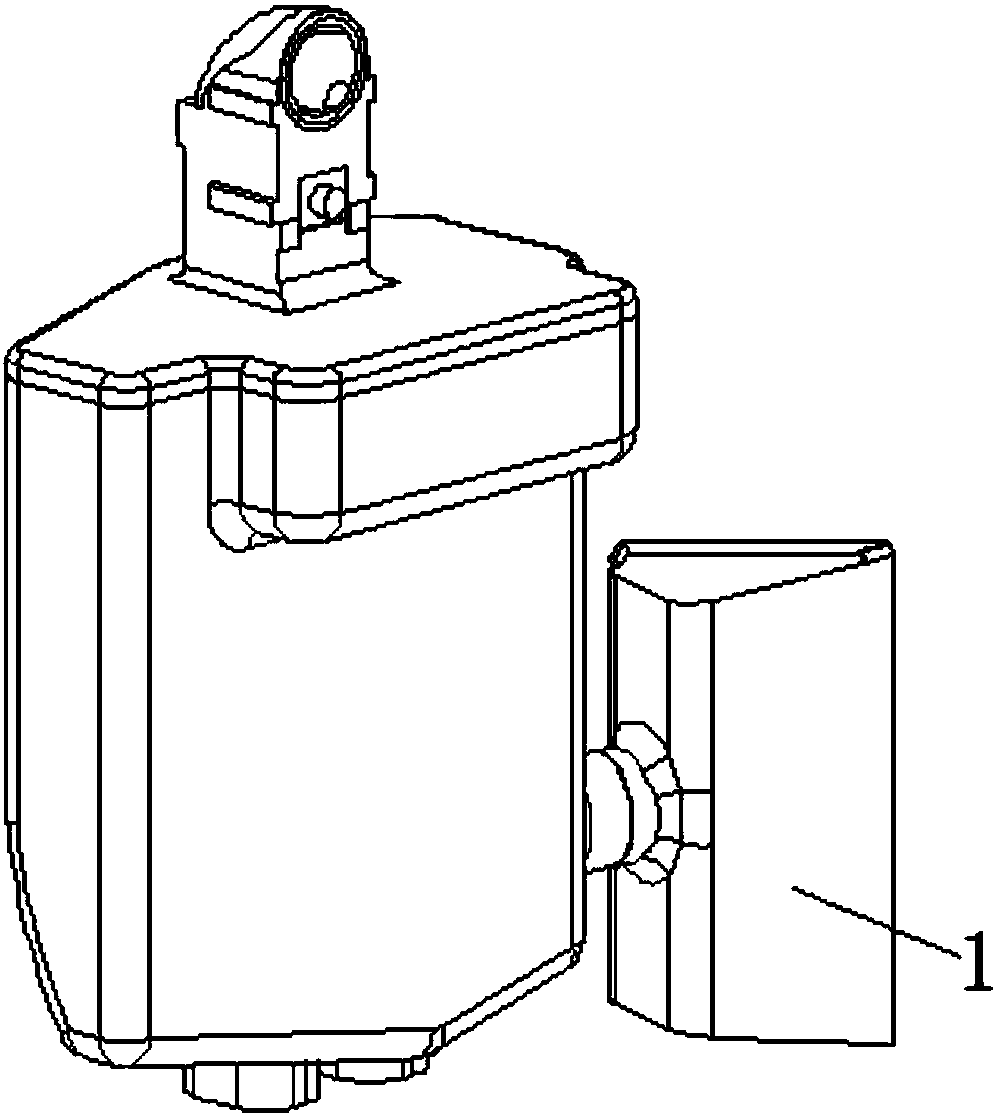

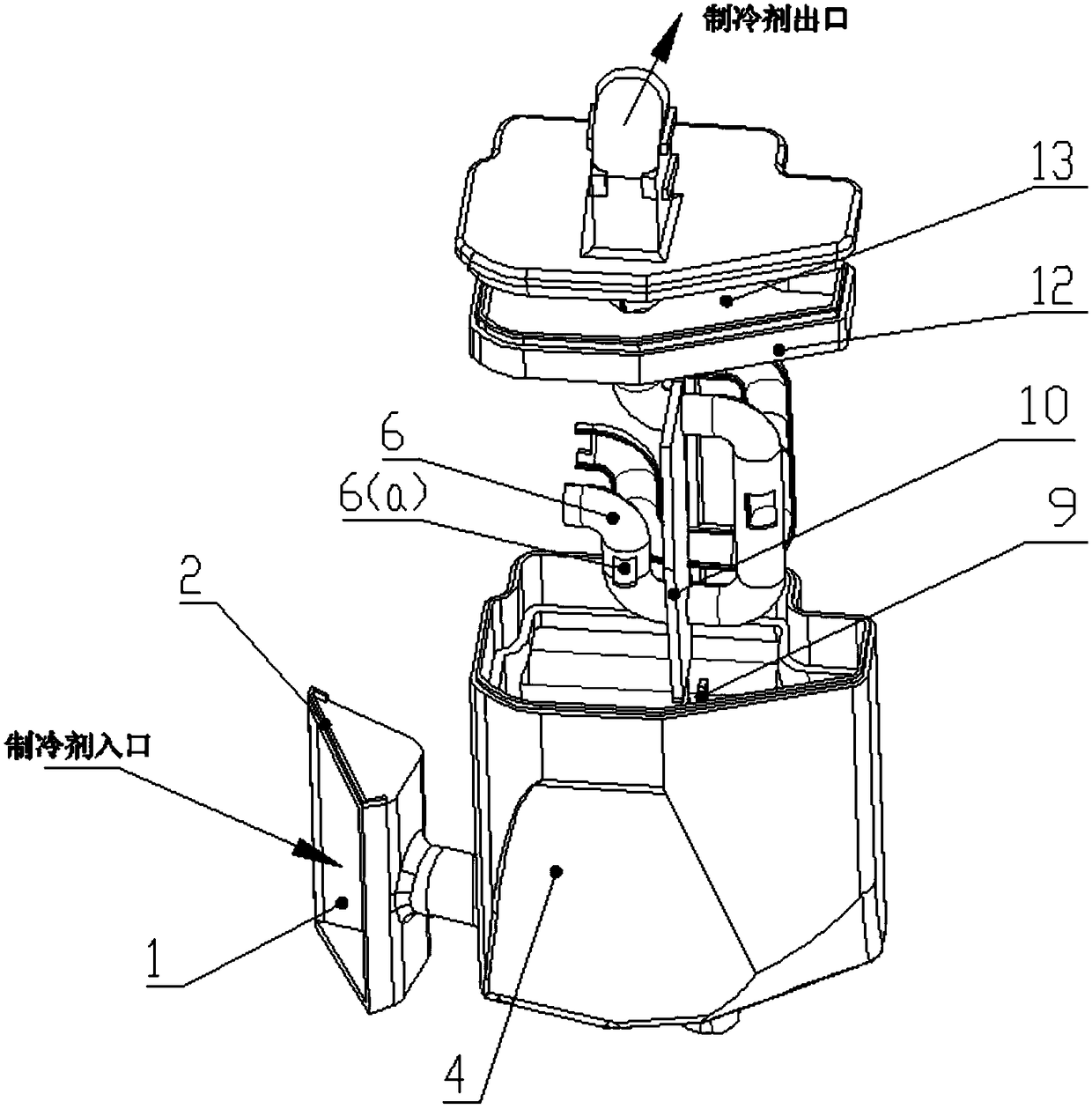

[0030] Such as Figure 1-Figure 4 As shown, this kind of reciprocating piston compressor for energy saving, noise reduction, noise reduction and vibration reduction includes a suction muffler connected to the cylinder seat, the gas outlet of the suction muffler is connected to the inlet port of the valve plate 19, and the suction muffler is connected to There is a refrigerant inlet 1; the refrigerant inlet 1 is a groove-shaped structure formed by connecting a V-shaped plate and an oil baffle plate 2 on both ends of the V-shaped plate, and the muffler is inserted into the muffler through one end 3 and the V-shaped plate Connection; there are three levels of anechoic chamber inside the muffler. Compared with the prior art, the suction muffler in the present invention has a large suction port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com