Air compressor

An air compressor and compressed air technology, which is applied in the direction of mechanical equipment, engine parameters, machines/engines, etc., can solve the problems of increasing the impedance of the motor part, poor lubrication, worn bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

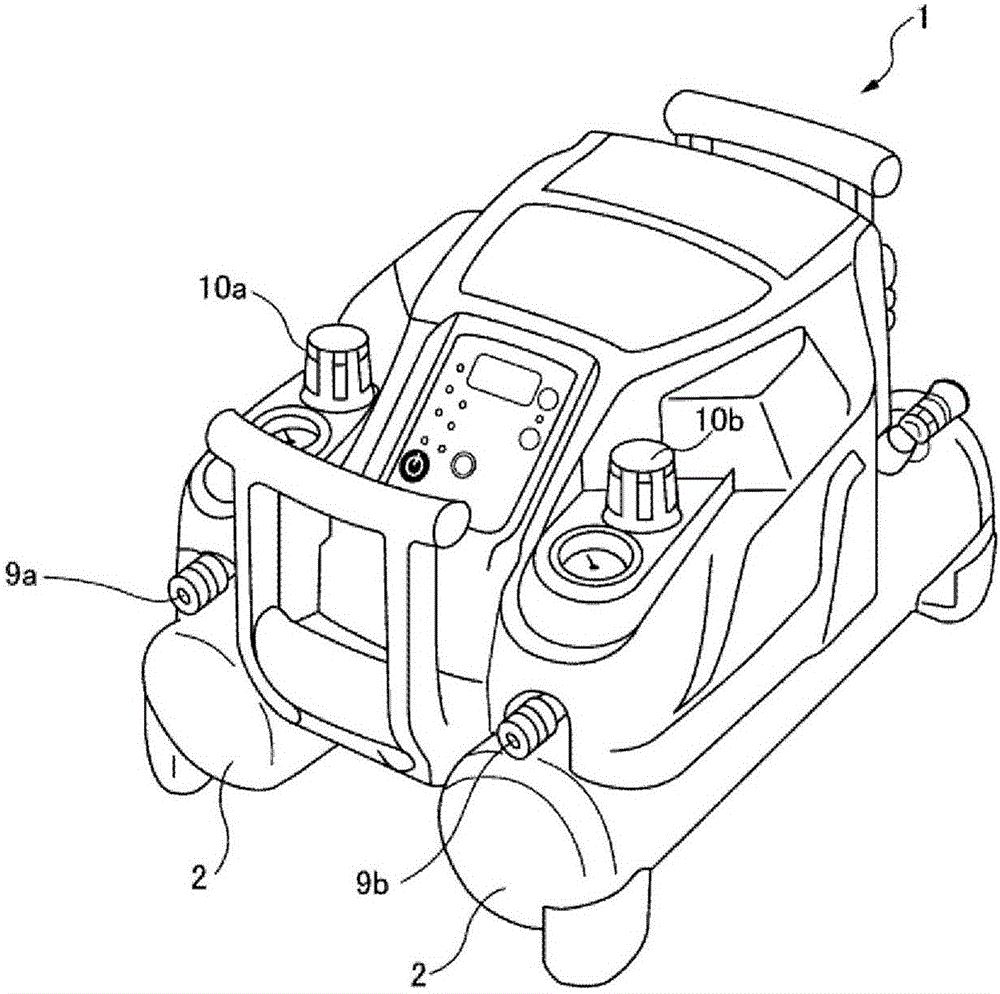

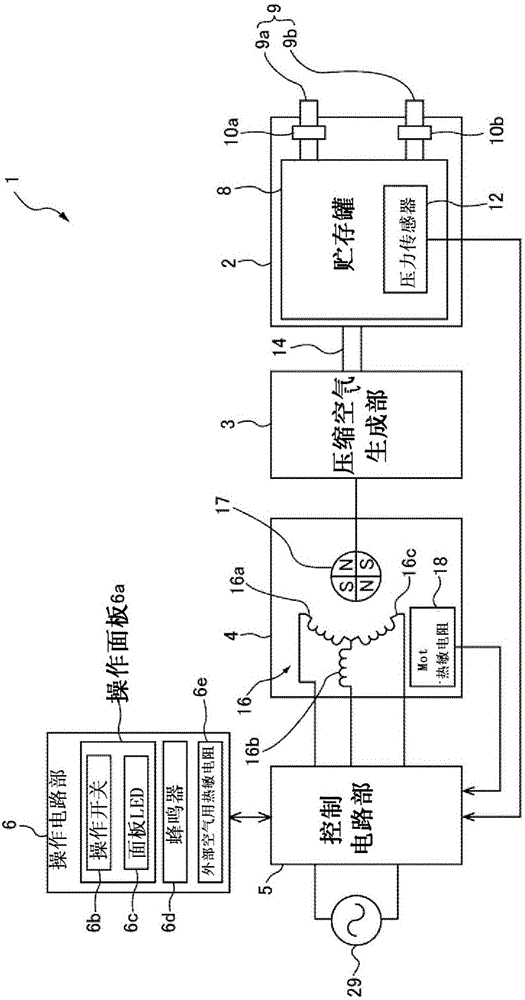

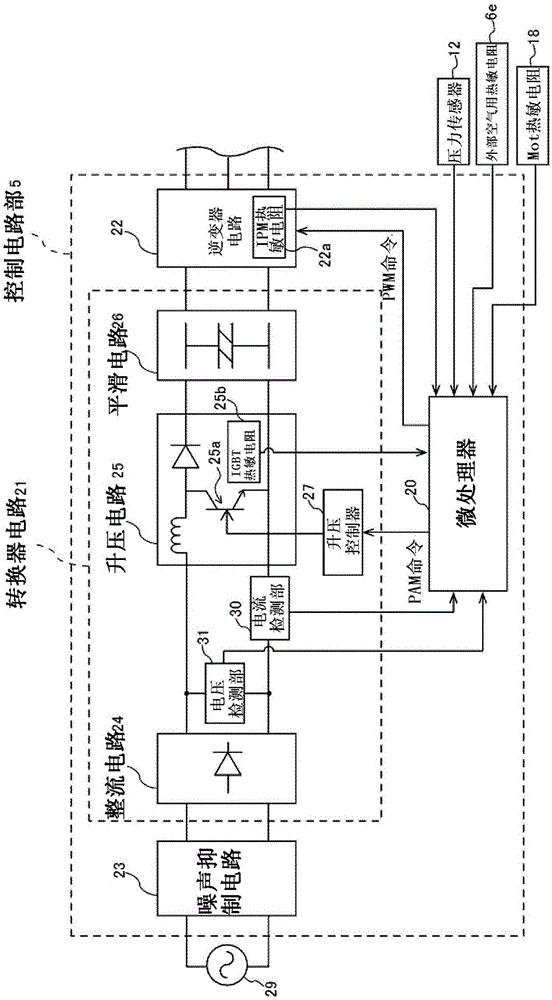

[0023] Hereinafter, an example of the compressor of the present invention will be shown and described in detail with reference to the drawings. figure 1 It is a perspective view showing the appearance of an air compressor, figure 2 It is a block diagram showing a schematic configuration of an air compressor. The air compressor 1 is schematically composed of a tank unit 2 , a compressed air generating unit 3 , a motor unit (motor unit) 4 , a control circuit unit 5 , and an operation circuit unit 6 .

[0024] The tank part 2 has a storage tank 8 for storing compressed air. Compressed air at a constant pressure generated by the compressed air generating unit 3 is stored in the storage tank 8 . The air compressor 1 according to the present embodiment is characterized in that the pressure of the storage tank 8 is changed according to the usage status of the drive tool.

[0025] A plurality of compressed air outlets 9 are provided in the storage tank 8 . In this embodiment, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com