Worm with built-in lubricating structure

A lubricating structure and built-in technology, applied to components with teeth, gear lubrication/cooling, hoisting devices, etc., can solve the problems of discounted lubricating effect, decreased lubricating oil viscosity, and affecting lubricating quality, so as to achieve sufficient lubricating, The effect of reducing the volume and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

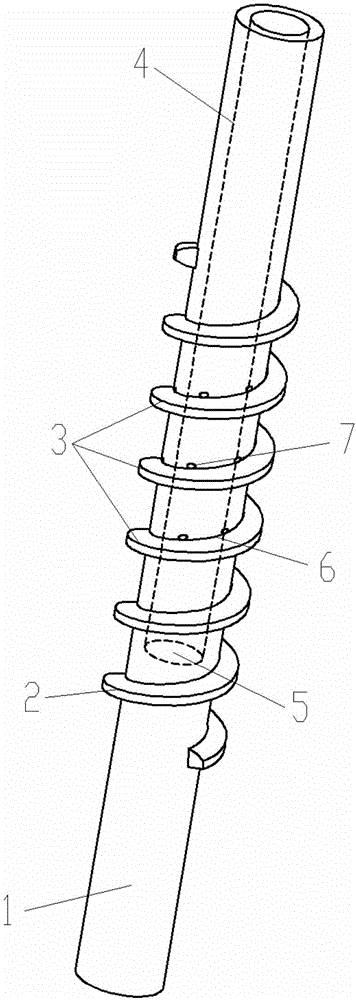

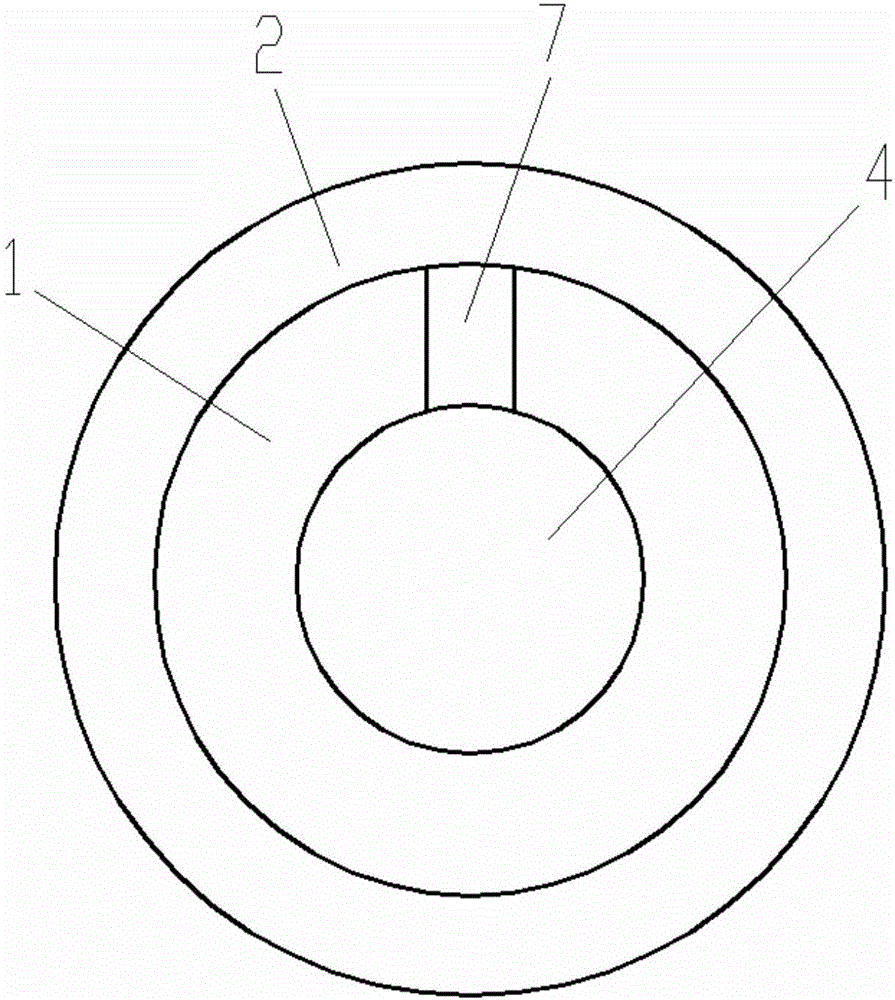

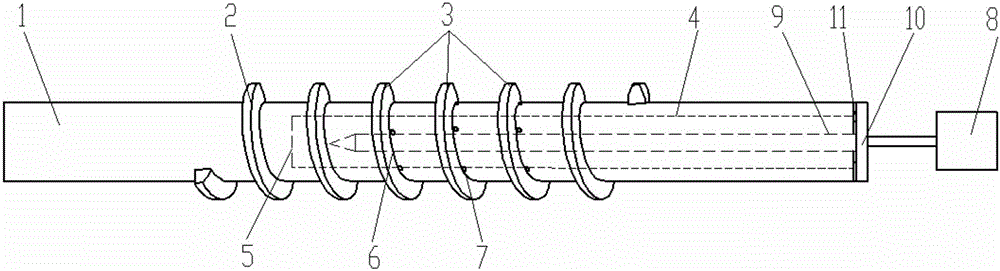

[0018] Attached below Figure 1-3 An embodiment of the present invention is described.

[0019] Worm with built-in lubrication structure, such as figure 1 As shown, the worm body 1 is included. The outer surface of the worm body 1 is provided with worm spiral teeth 2. During the working process of the worm, only a part of the worm spiral teeth 2 meshes with the worm wheel, and the worm spiral teeth 2 mesh with the worm wheel. It is set as the worm meshing tooth part 3, and the use rate of the worm meshing tooth part 3 is high, so the lubrication system is also high. In this solution, a gear pump 8 is added to the worm gear box, and the lubrication structure of the worm is changed to achieve a better lubrication effect. That is, under the premise of ensuring the transmission strength of the worm, a blind hole 4 is drilled at one end of the worm body 1 to ensure that the worm meshing teeth 3 of the worm meshing with the worm wheel are effectively lubricated, so that the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com