Improved passive automatic fire-fighting spray valve

A spray valve and improved technology, applied in valve details, valve devices, engine components, etc., can solve the problems of complex structure, complicated manufacturing and assembly, and decreased sensitivity of the spray valve, and achieve simple structure, easy processing and assembly. , the effect of sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

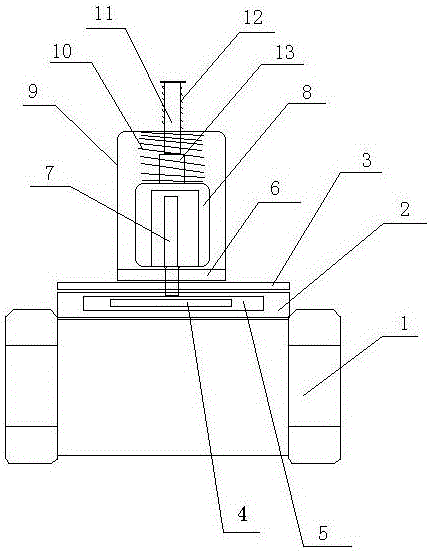

[0028] In order to describe the technical solution of the present invention in more detail, it will be described in detail in conjunction with the accompanying drawings, specifically as follows:

[0029] Such as figure 1 As shown, an improved passive automatic fire sprinkler valve includes a valve body 1, a valve core and a passive power module;

[0030] The valve body 1 has three through holes, the through holes at the left and right ends of the valve body are water inlet and water outlet respectively, and the middle through hole of the valve body is provided with a valve core;

[0031] The top of the through hole in the middle of the valve body is provided with a passive power module fixed support 2;

[0032] The lower part of the valve core is sheet-shaped and separates the water inlet and the water outlet of the valve body. The upper part of the valve core is a cylinder, and there is a hollow cylinder in the center of the cylinder. The hollow cylinder communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com