Embedded piezoelectric drive micro oil spraying lubrication device

A technology of piezoelectric drive and oil injection lubrication, which is applied in the direction of dosing device, engine lubrication, distribution device, etc., can solve the problem that micro-redundant supplementary oil supply lubrication is difficult to realize, and achieve light weight, small volume and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

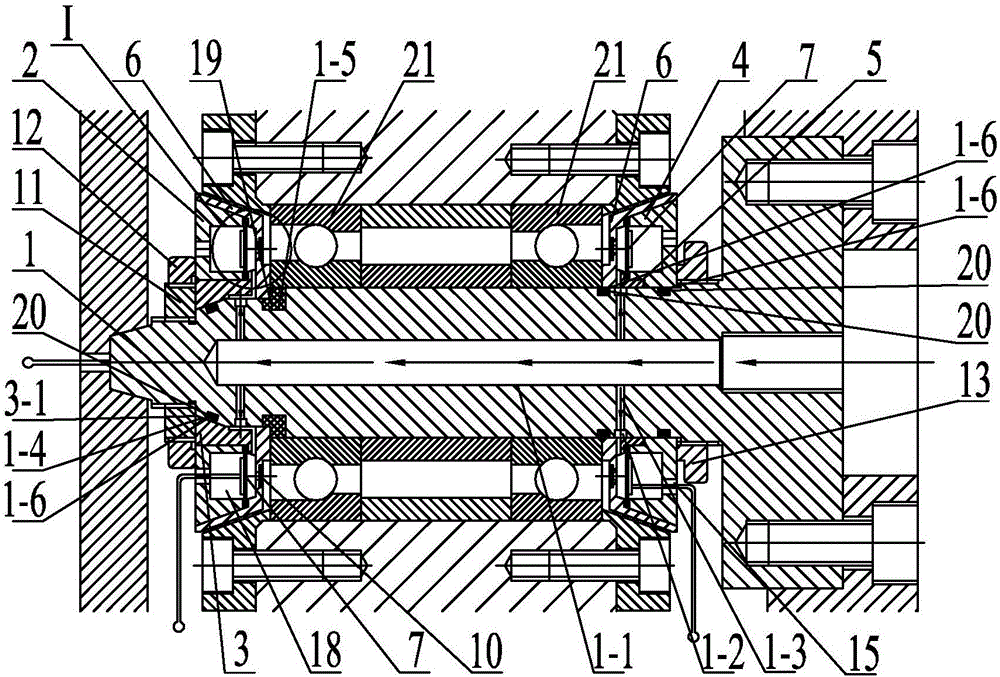

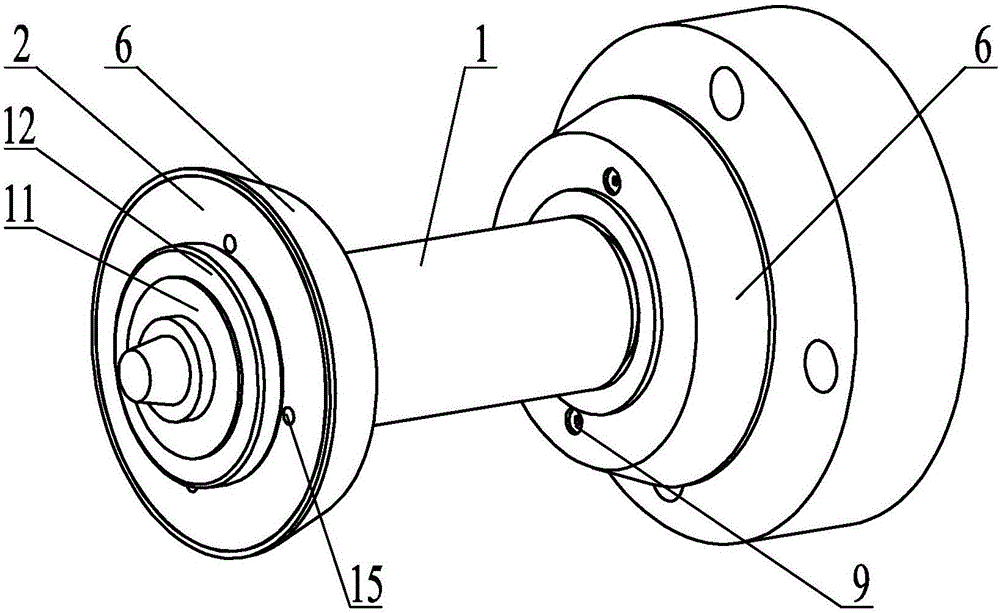

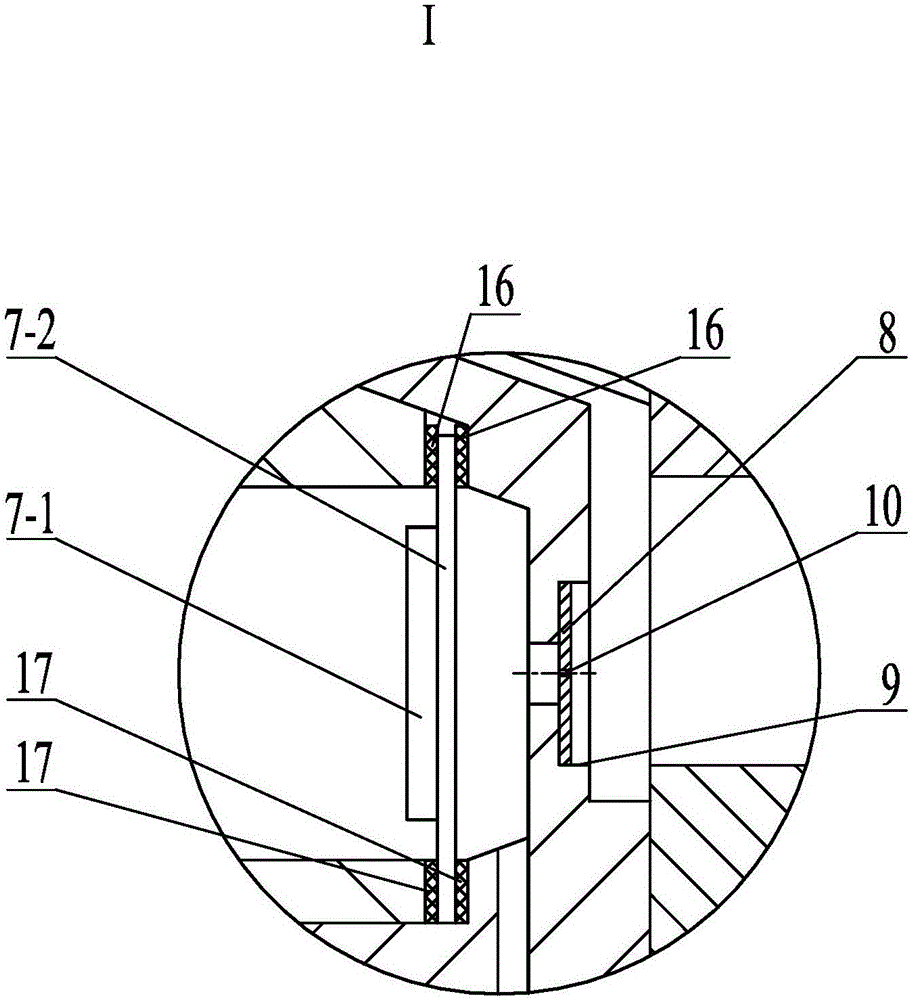

[0021] Specific implementation mode one: combine Figure 1 to Figure 7 To illustrate, an embedded piezoelectric-driven micro-spray lubrication device described in this embodiment includes a mandrel 1, a front micro-spray cover 2, a front guide ring 3, a rear micro-spray cover 4, a rear guide ring 5, two The micro-spray chamber body 6, two piezoelectric vibrators 7 and four metal discs 8, the central part of the mandrel 1 is provided with a hollow channel 1-1 along the axial direction, the shape of the micro-spray chamber body 6 is ring-shaped, and the mandrel The front and rear ends of 1 are respectively equipped with a micro-spray cavity body 6, the shape of the cross-section of the micro-spray cavity body 6 is conical, and the small end faces of the two micro-spray cavity bodies 6 are oppositely arranged, and each micro-spray cavity body 6 Two circular grooves 9 are respectively arranged symmetrically along the radial direction on the small end surface, and a metal disc 8 is...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination Figure 1 to Figure 2 Explanation, the large end faces of the front micro-spray cover 2 and the rear micro-spray cover 4 in this embodiment are respectively provided with through holes 15, and the positive lead wire of the driving power is connected to the top of the annular piezoelectric ceramic sheet 7-1 in the piezoelectric vibrator 7. surface, and drawn out from the through hole 15, the negative electrode lead is connected to the mandrel 1. Other compositions and connection methods are the same as those in Embodiment 1.

[0026] When the piezoelectric-driven micro-spray lubrication device of this embodiment is applied, the positive lead of the piezoelectric vibrator 7 is connected to the upper surface of the annular piezoelectric ceramic 7-1, drawn out from the through hole 15, and connected to the signal generating end of the driving power supply. The negative lead wire can be directly connected to the metal outer wall...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination Figure 1 to Figure 3 and Figure 6 To illustrate, the annular piezoelectric ceramic sheet 7 - 1 in the piezoelectric vibrator 7 in this embodiment is polarized in the thickness direction. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0028] In such a design, the annular piezoelectric ceramic sheet 7-1 adopts the method of polarization in the thickness direction, and a voltage pulse excitation of a certain frequency and waveform is applied to its upper and lower surfaces to increase the bending deformation of the piezoelectric vibrator 7, thereby increasing the volume of the liquid cavity. As the variation increases, the resulting acoustic pressure wave increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com