Multipurpose type drying device

A drying equipment and multi-purpose technology, which is applied in drying, dryers, lighting and heating equipment, etc., can solve the problems of low utilization rate of drying equipment, high cost, and serious pollution of the environment, so as to facilitate popularization and use, High utilization rate and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides many applicable creative concepts, which can be embodied in a large number of specific contexts. The specific examples described in the following embodiments of the present invention are merely illustrative of specific embodiments of the present invention, and do not constitute a limitation on the scope of the present invention.

[0031] The present invention will be further described below in conjunction with the drawings and specific implementations.

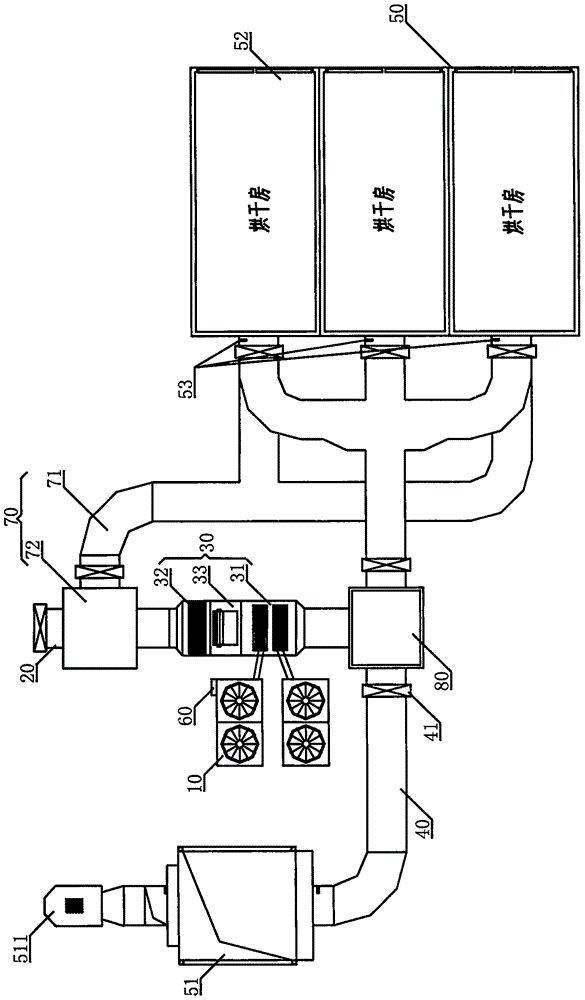

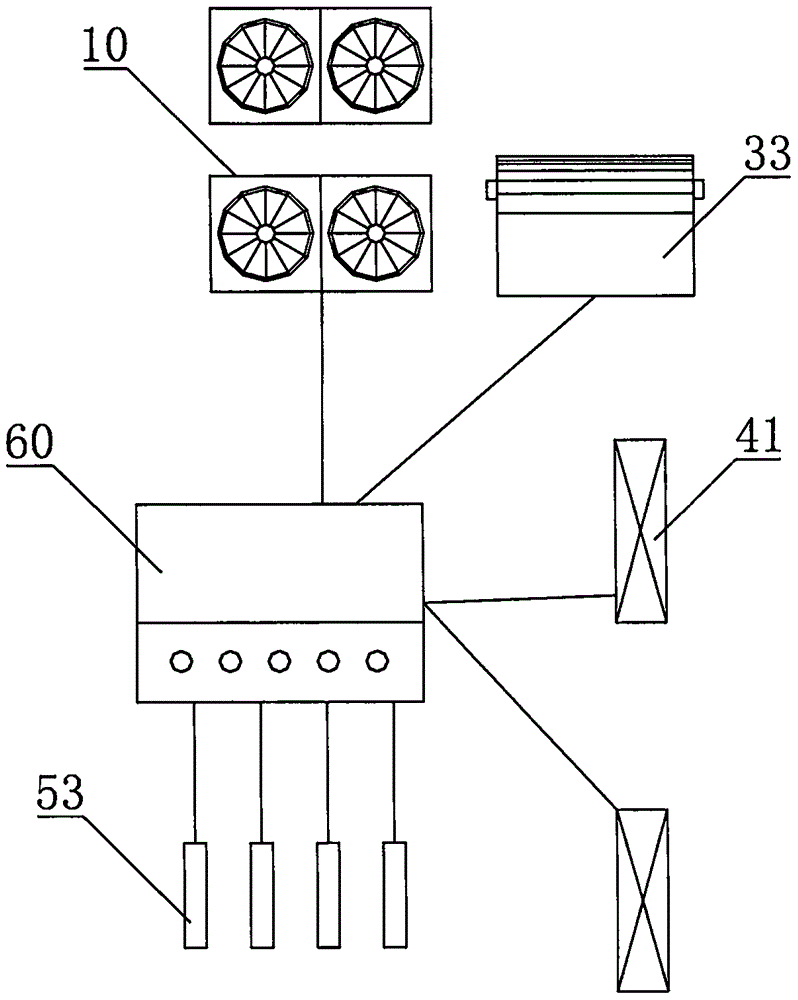

[0032] This embodiment provides a multi-purpose drying equipment, such as figure 1 As shown, it includes a heat pump 10, an air inlet passage 20, a heat exchange unit 30, a supply air passage 40 and a material drying chamber 50. The heat exchange unit 30 includes a heat exchanger 31, and the fresh air inlet of the heat exchanger 31 is connected to the inlet In the air passage 20, the heat source inlet of the heat exchanger 31 is connected to the heat pump 10, the heating outlet of the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com