A system and method for automatic calculation of product measurement points based on laser-guided measurement

An automatic calculation and guided technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of inability to consider product changes and low measurement accuracy, so as to reduce teaching time, improve accuracy, and eliminate errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

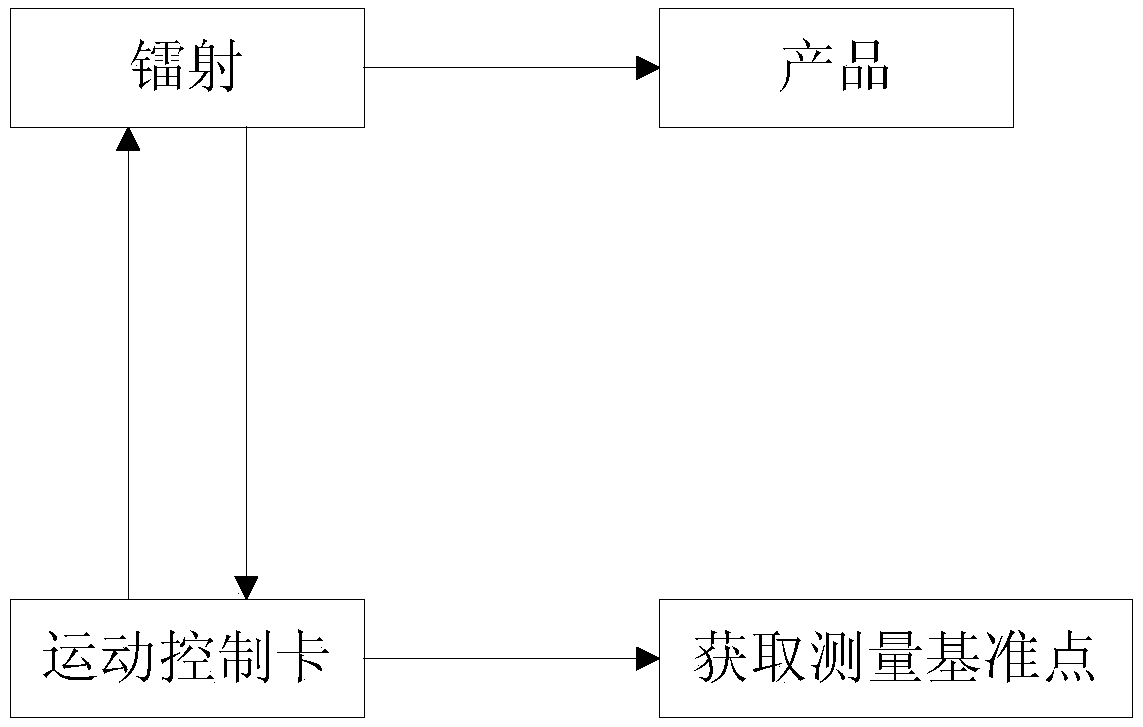

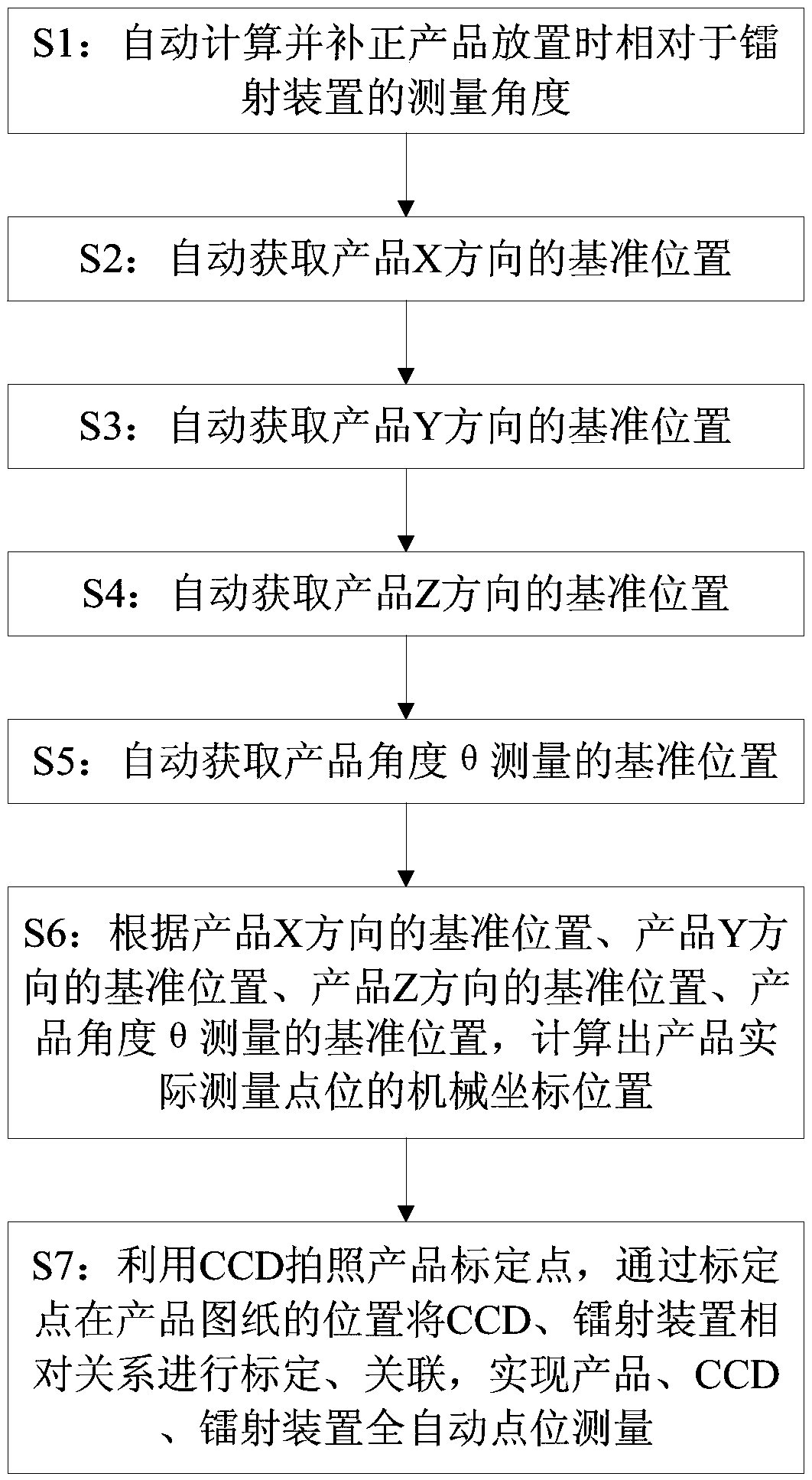

[0051] Such as figure 1 As shown, the automatic calculation system for three-dimensional measurement points of regular products based on 2D laser-guided measurement of the present invention includes:

[0052] A motion control device, the motion control device includes a motion control card and a motion mechanism, the motion control card is used to control the motion mechanism to perform linear motion in three-dimensional directions, and obtain the current position information of the motion mechanism. In this embodiment, the motion control card is an IMAX-LX series motion control card. The IMAX-LX series motion control card has a pulse signal capture channel up to 1MHZ and a high-precision PID control function.

[0053] A laser device, the laser device is arranged on the motion control device, and the laser device is used to detect the measuring point of the product and send a signal to the motion control card. In this embodiment, the laser device is selected from LJ-V series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com