Simulation apparatus and simulation method of atmosphere corrosion

A technology of atmospheric corrosion and simulation devices, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

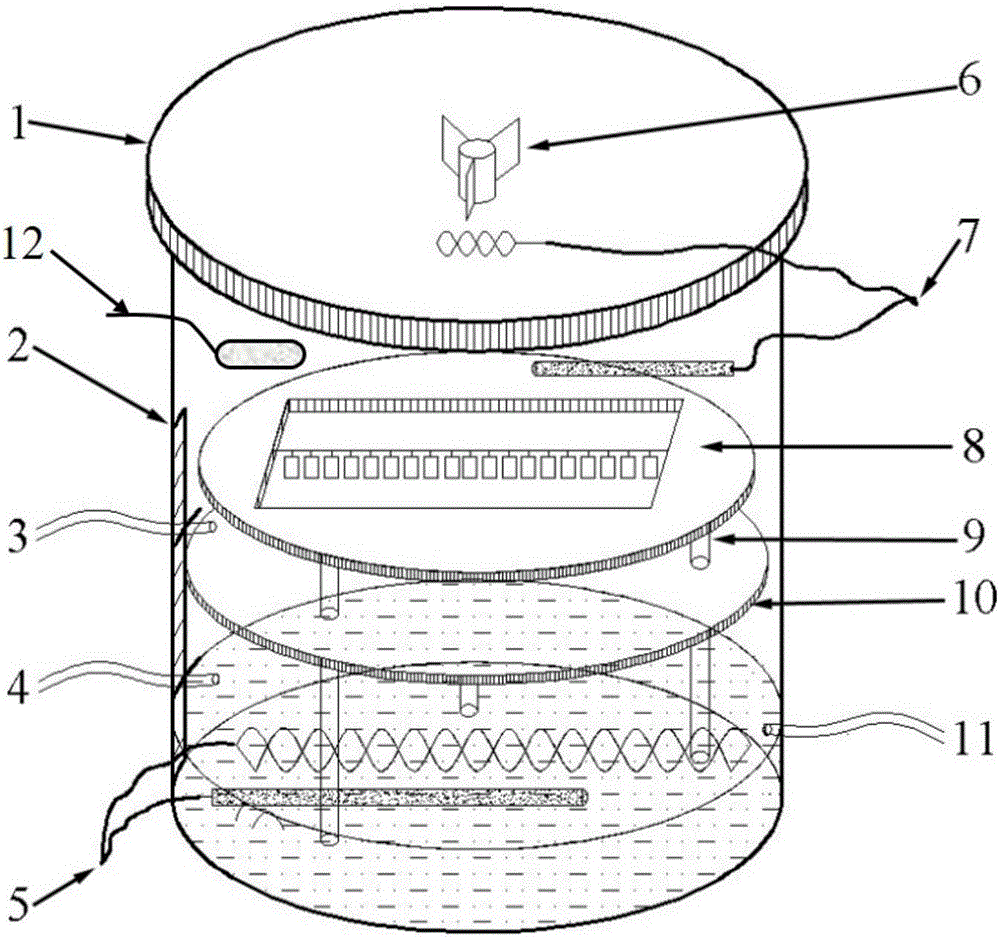

Method used

Image

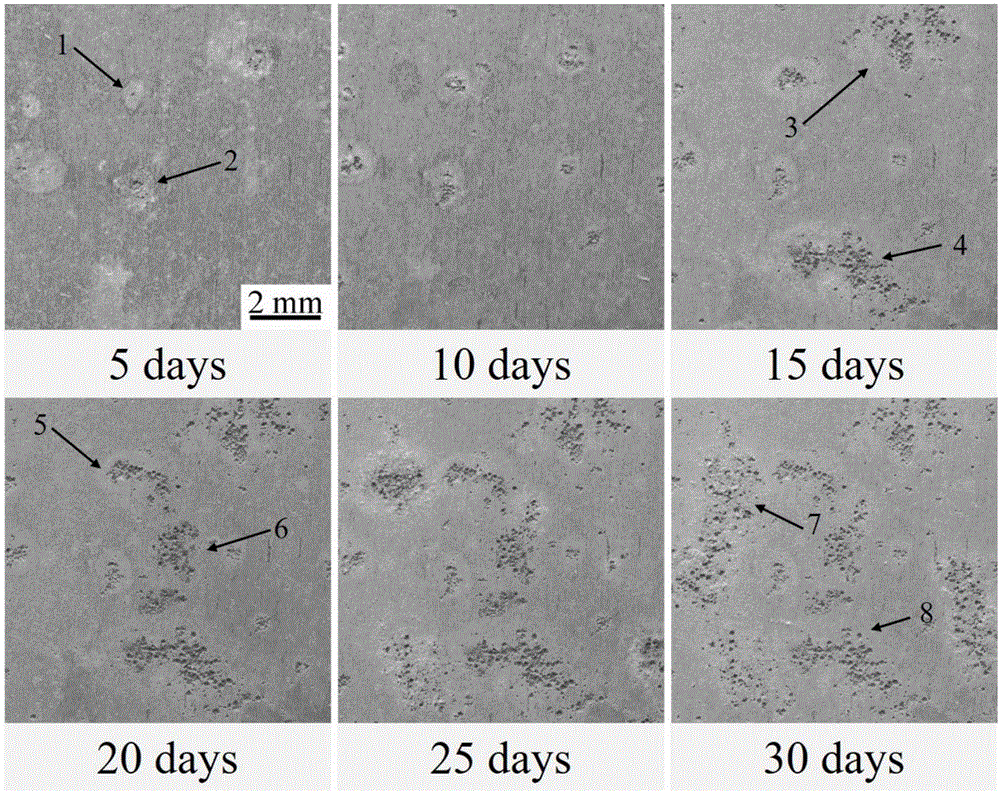

Examples

Embodiment 1

[0041]In this embodiment, the corrosive medium solution was selected from sodium chloride solution, which was passed into the above-mentioned simulation experiment device, and the temperature of the industrial pure aluminum 1035 to be tested was adjusted by controlling the water inlet one, the water outlet one and the water outlet two. state.

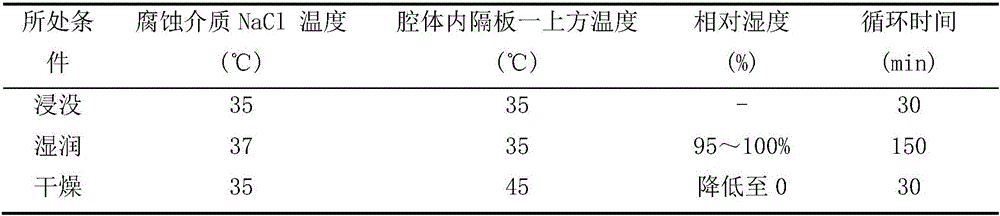

[0042] The specific method is: the medium used is 0.6M NaCl+0.15M Na 2 SO 4 The solution comes from a simulated marine-industrial atmospheric environment with high temperature and high humidity, and the solution temperature is kept at 35°C. In the submerged state, the air temperature in the upper cavity is 35°C, and each cycle is 30 minutes; in the wet state, the air temperature in the upper cavity is still 35°C, and the temperature of the lower solution is 37°C. At this time, the relative humidity of the environment where the sample is located Reach 95%-100%, 150 minutes per cycle; in the dry state, the temperature in the upper cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com