Corrosion fatigue life prediction method based on BP neural network and application

A BP neural network and corrosion fatigue technology, applied in the field of engineering mechanics, can solve the problems of predicting corrosion fatigue life, large randomness of influencing factors, low service life of high-strength sucker rods and low design life, so as to achieve engineering application and popularization Strong, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

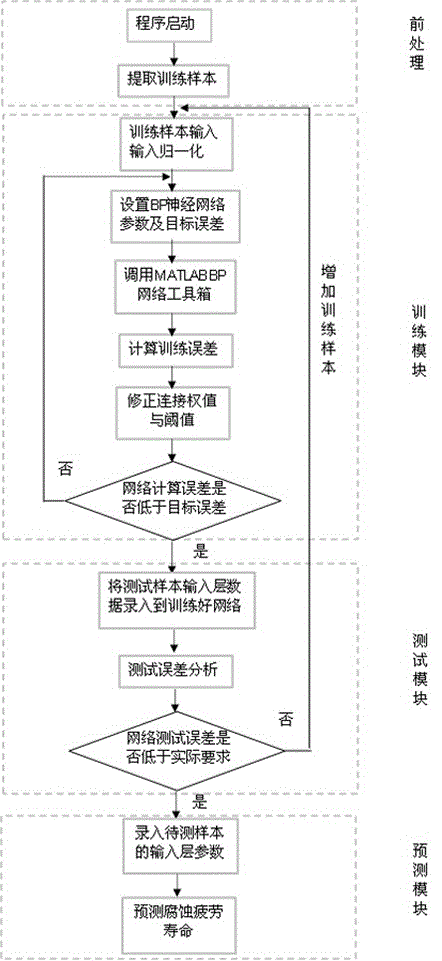

[0029] Such as figure 1 As shown, the corrosion fatigue life prediction method based on BP neural network includes the following steps:

[0030] Step 1. Collation of material corrosion fatigue cycle failure test data, the specific method is as follows:

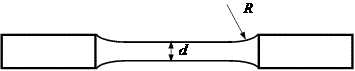

[0031] Process high-strength sucker rod materials into rod-shaped samples, such as figure 2 As shown, the two ends of the sample are cylindrical, which is convenient for clamping; the middle of the sample is the test part, which is cylindrical with variable cross-section, and is made of cross-grinding with a forming grinding wheel. The radius R of the transition arc is not less than 5 times the diameter d of the smallest section times.

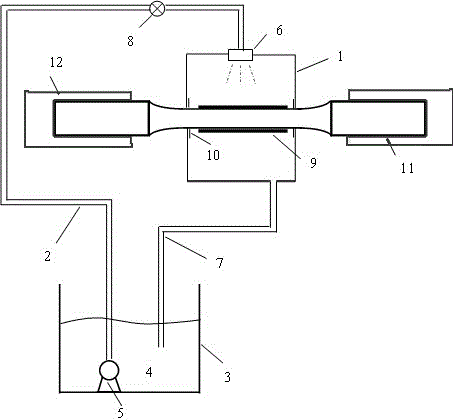

[0032] In order to ensure that the surface of the sample is affected by the corrosive solution, the corrosive solution and circulation device are designed, such as image 3 As shown, it includes: square container 1, corrosion-resistant hose 2, corrosion solution circulation box 3 and corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com