A one-pot method for the synthesis of copper nanowire gels

A technology of copper nanowires and copper nitrate, applied in gel electrodes, active material electrodes, electrical components, etc., can solve the problems of single function of negative current collectors and less research on negative current collectors, and meet the requirements of easy industrial amplification and experimental equipment. Low, simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

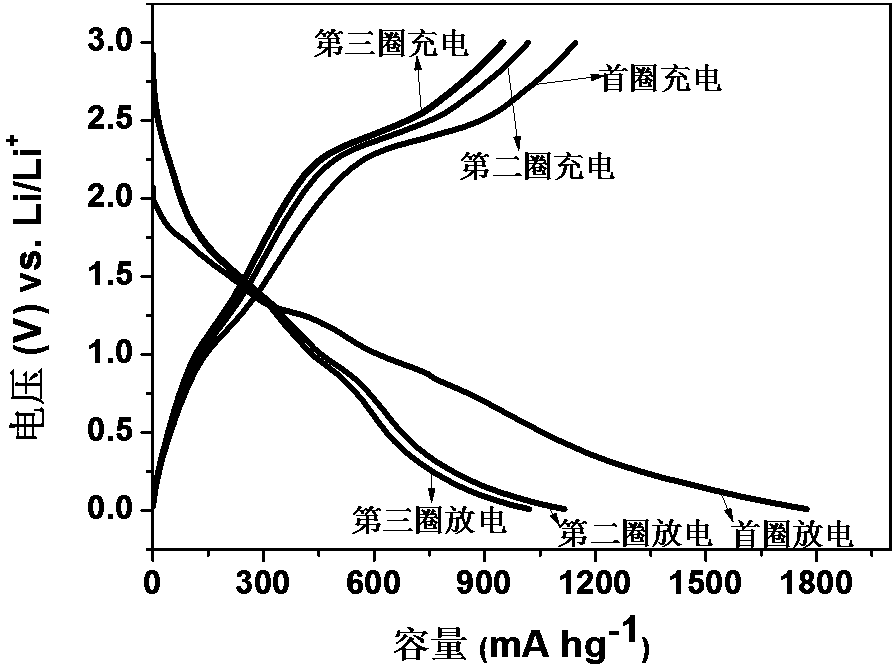

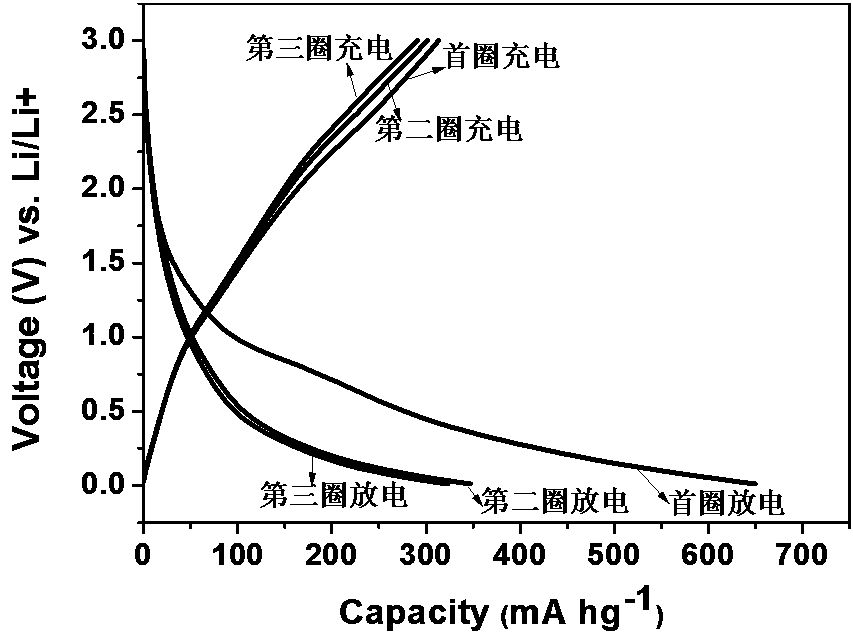

Image

Examples

Embodiment

[0017] 1. Pretreatment of raw materials;

[0018] Accurately weigh 0.488g of copper nitrate dihydrate, 120g of sodium hydroxide, and 3g of ascorbic acid, and configure them into copper nitrate of 2mmol / L, 15mol / L of sodium hydroxide, and 17mmol / L of ascorbic acid, mix and stir evenly, and measure 3 ml of ethylenediamine, which was then added to the previous mixture, still stirring and eventually a blue suspension formed.

[0019] 2. making process;

[0020] After the blue suspension was stirred and reacted at 80°C for 38-45 minutes, the heating was stopped quickly and the reactor was placed in the air to cool naturally. After about 10 minutes, the red substance was precipitated and the copper nanowire wet gel was obtained.

[0021] 3. drying process;

[0022] The nanowire wet gel was left to age for 2 days to increase its copper nanowire toughness. After the aging is completed, filter and finally dry the copper nanowire wet gel at 80° C. for 5 hours in vacuum to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com