Atmospheric corrosivity on-line monitoring system and method

An atmospheric corrosion and monitoring system technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of poor accuracy, long cycle of atmospheric environmental factors, and long cycle, so as to shorten the cycle and improve monitoring The effect of accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

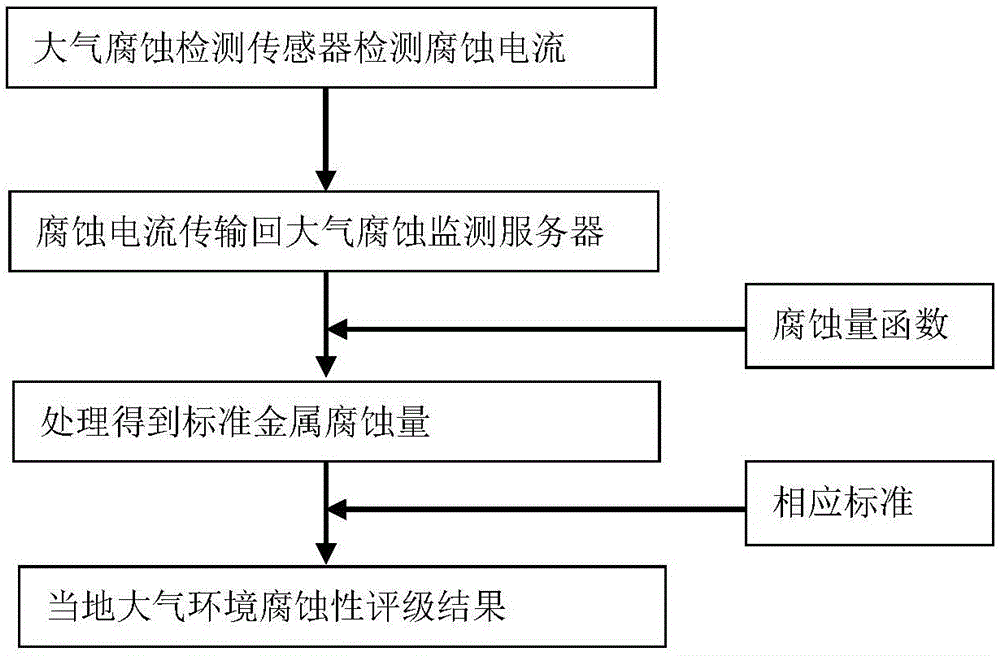

[0031] In the present invention, the standards involved in comparing the metal corrosion amount with the preset corresponding standard are: standard ISO9223 or national standard GB19292 or other standards.

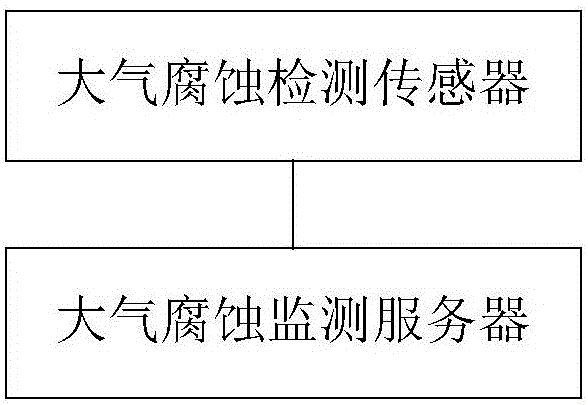

[0032] figure 1 It is a structural schematic diagram of the atmospheric corrosion online monitoring system of the present invention. The atmospheric corrosion online monitoring system as shown in the figure includes an atmospheric corrosion detection sensor arranged at a predetermined position in the area to be monitored. The atmospheric corrosion detection sensor is configured to detect Atmospheric corrosion current at a predetermined location in the monitoring area and sent to the atmospheric corrosion monitoring server;

[0033] The atmospheric corrosion monitoring server is configured to convert the received atmospheric corrosion current within a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com