Rapid preparation method of composite material ti/al3ti based on ultrasonic consolidation forming

A technology of ultrasonic consolidation and composite materials, applied in chemical instruments and methods, layered products, layered product processing, etc., to achieve the effects of simple and easy process, short preparation period and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

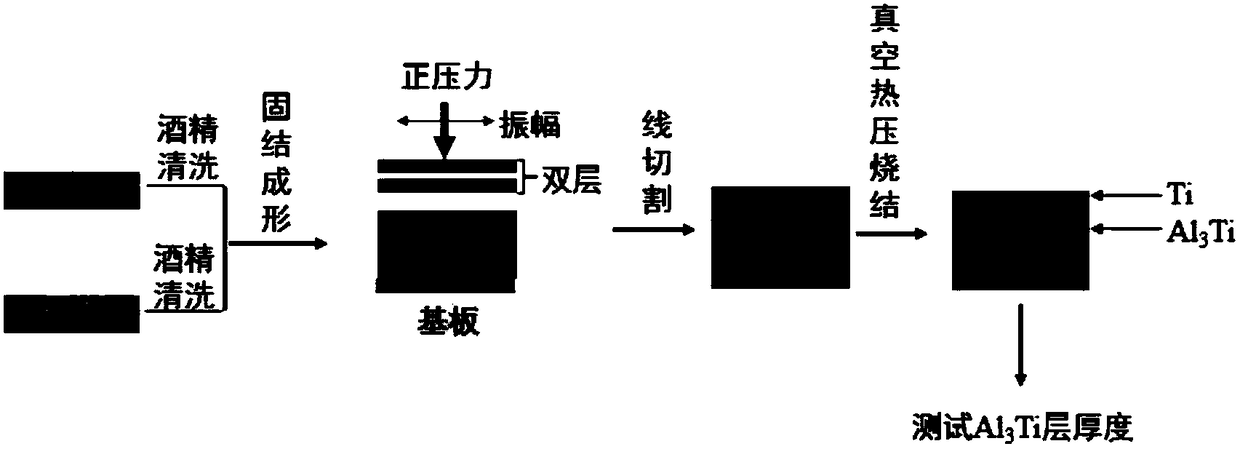

[0028] Preparation method of the present invention:

[0029] The first is the pretreatment of Al1100 and TA1 metal strips:

[0030] (1) Cut Al1100 and TA1 strips with a length and width of 800mm×24.5mm and a thickness of 200μm;

[0031] (2) Place the cut metal strip in an ultrasonic cleaner and clean it with alcohol for 15-20 minutes.

[0032] Secondly, stack them in the order of "Ti strip-Al strip", and finally prepare Ti / Al prefabricated strips by using ultrasonic consolidation rapid prototyping equipment;

[0033] Finally, the Ti / Al prefabricated strip prepared by ultrasonic consolidation rapid prototyping was peeled off from the substrate, and placed in a vacuum hot-press furnace for sintering to prepare a Ti / Al3Ti layered composite material. The test principle and flow chart are attached. figure 1 .

[0034] Main process parameters:

[0035] Ultrasonic consolidation rapid prototyping parameters: substrate preheating temperature 150℃~200℃, ultrasonic consolidation rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com