Train running speed detection method and system based on ballastless track

A ballastless track and running speed technology, applied in railway signaling and safety, etc., can solve problems such as speed calculation error, speed measurement error, wheel diameter change, etc., and achieve the effects of easy control, reliable operation and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

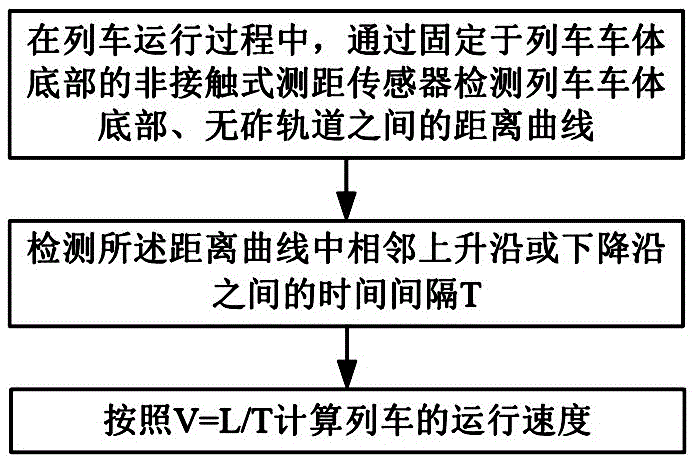

[0029] Such as figure 1 As shown, the steps of the train running speed detection method based on ballastless track in this embodiment include:

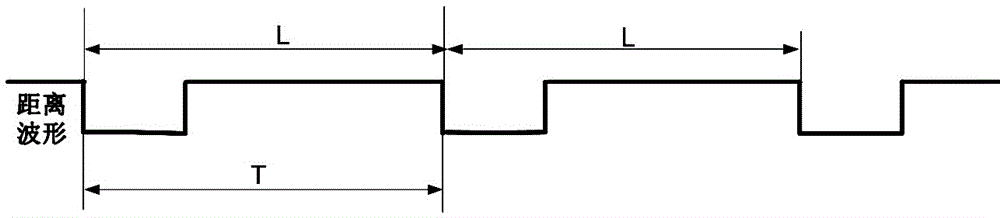

[0030] 1) During the operation of the train, the distance curve between the non-contact ranging sensor and the ballastless track is detected by the non-contact ranging sensor fixed on the bottom of the train body or the bogie. Arranged sleepers such as figure 2 As shown, the distance curve is a periodic square wave curve, and a periodic waveform in the distance curve is composed of the first distance of the sleeper area and the second distance of the non-sleeper area; see figure 2 , where L represents the distance between adjacent sleepers on the ballastless track, and T represents the time interval between adjacent rising or falling edges in the distance curve, that is, the time length of a periodic waveform (waveform period of the distance curve);

[0031] 2) The time interval T between adjacent rising or falling edges in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com