High-temperature-resistant shielding paint and preparation method thereof

A technology of shielding coatings and high-temperature-resistant fillers, applied in coatings and other directions, can solve the problems of poor coating flexibility, easy breakage of bonds, and loss of shielding effect of materials, achieving light weight and good radiation protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of high temperature resistant shielding coating, comprising the following steps:

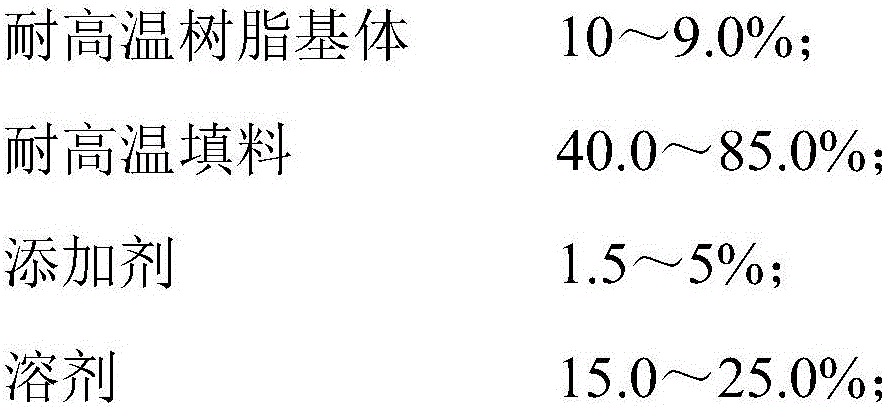

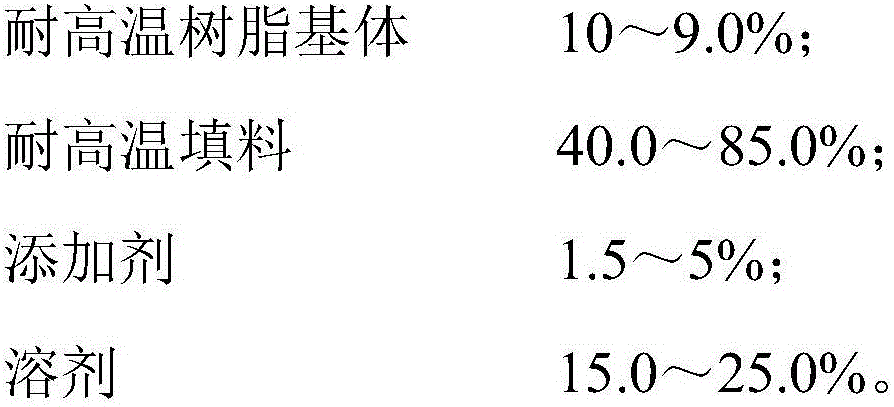

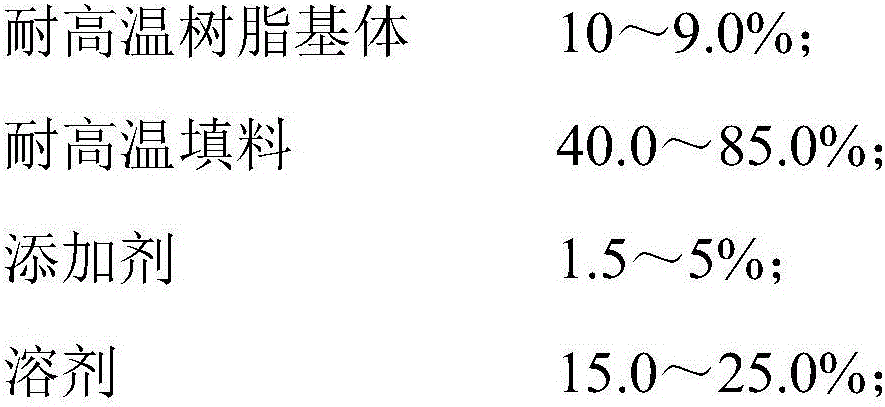

[0034] S1. Add 10-9.0% of high temperature resistant resin matrix, 1.5-5% of additives and 15.0-25.0% of solvent into the reaction kettle according to mass percentage, and stir evenly under the condition of stirring speed of 1000-1200rpm.

[0035] S2. After adding 40.0-85.0% high-temperature-resistant filler under the condition of rotating speed of 500-600 rpm, stirring for 30 minutes until uniformly mixed under the condition of rotating speed of 1000-1200 rpm.

[0036] S3. Grinding the homogeneously mixed slurry on a three-roll machine for 3 to 5 times until the fineness is below 30 μm to obtain a high temperature resistant shielding coating.

Embodiment 1

[0039] Add 20g of high-temperature-resistant resin, 16g of solvent, and 1.2g of additives (except toughening materials) into the beaker. After stirring for 30 minutes at a speed of 1200rpm with a high-speed mixer, adjust the speed to 500rpm, and slowly add 10g of high-temperature-resistant filler. After adding the high-temperature-resistant filler, adjust the rotation speed to 1000rpm; and stir for 30 minutes, then add 2g of toughening material. Grinding on a roller machine, grinding 3 times to a fineness of 20 μm, to obtain a high temperature resistant shielding coating.

[0040] Spray the prepared coating horizontally on a 120mm×25mm tin plate, the wet weight of spraying can reach 12g, and the prepared coating of 0.5mm is subjected to high temperature for 5 hours until it is completely cured. The prepared coating is heat-treated at a high temperature of 500°C for 40 hours, the flexibility of the coating is ≤15mm, and the density is 1.79g / cm 3 , and the reflection loss of th...

Embodiment 2

[0042] Add 24g of high-temperature-resistant resin, 18g of solvent, and 1g of additives (except toughening materials) into the beaker. After stirring for 30 minutes at a speed of 1200rpm with a high-speed mixer, adjust the speed to 600rpm, and slowly add 8.5g of high-temperature-resistant filler. After adding the high temperature resistant filler, adjust the rotation speed to 1200rpm; and stir for 30 minutes, then add 2.8g of toughening material. Grinding is carried out on a three-roll machine, and the grinding is performed 5 times until the fineness is 25 μm to obtain a high-temperature-resistant shielding coating.

[0043] Spray the prepared coating horizontally on a 120mm×25mm tin plate, the wet weight of spraying can reach 9.6g, and the prepared coating of 0.5mm is subjected to high temperature for 5 hours until it is completely cured. The prepared coating is heat-treated at a high temperature of 550°C for 60 hours, the flexibility of the coating is ≤15mm, and the density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com