A kind of gas hydrate promoter and preparation method thereof

A gas hydrate and accelerator technology, which is applied in gas fuels, chemical instruments and methods, and other chemical processes, etc., can solve the problems of insufficient hydrate promotion efficiency, low recycling rate, hindering hydrate, etc., so as to shorten the generation time. time, the effect of promoting good, the effect of reducing the balance point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

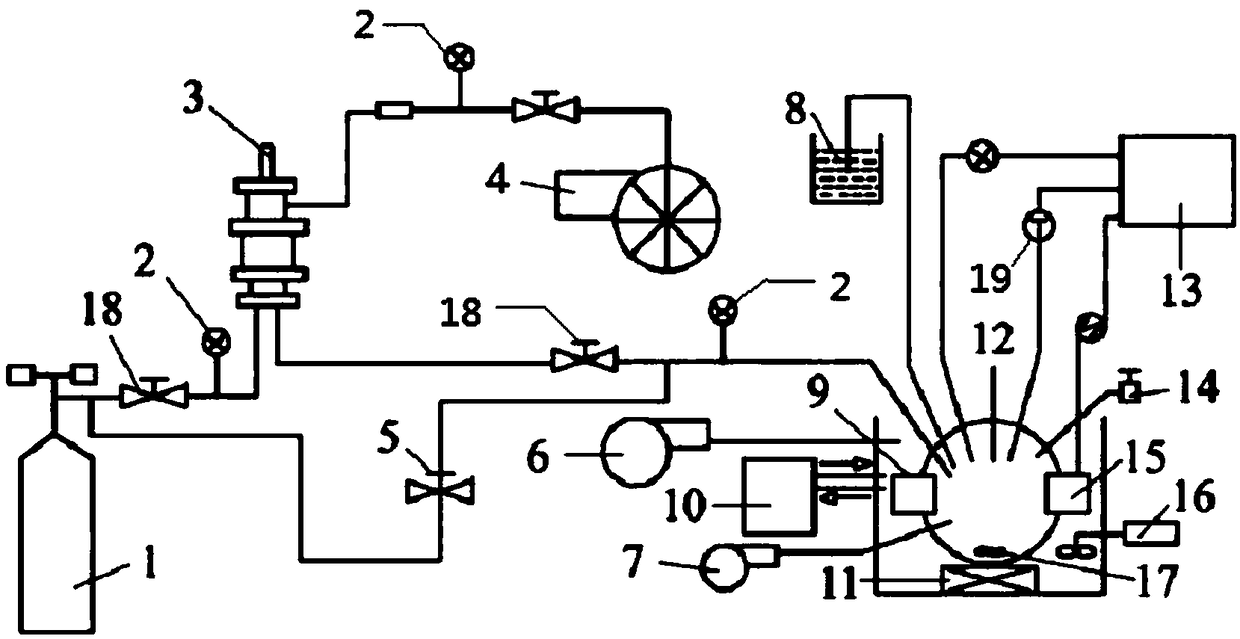

Method used

Image

Examples

Embodiment 1

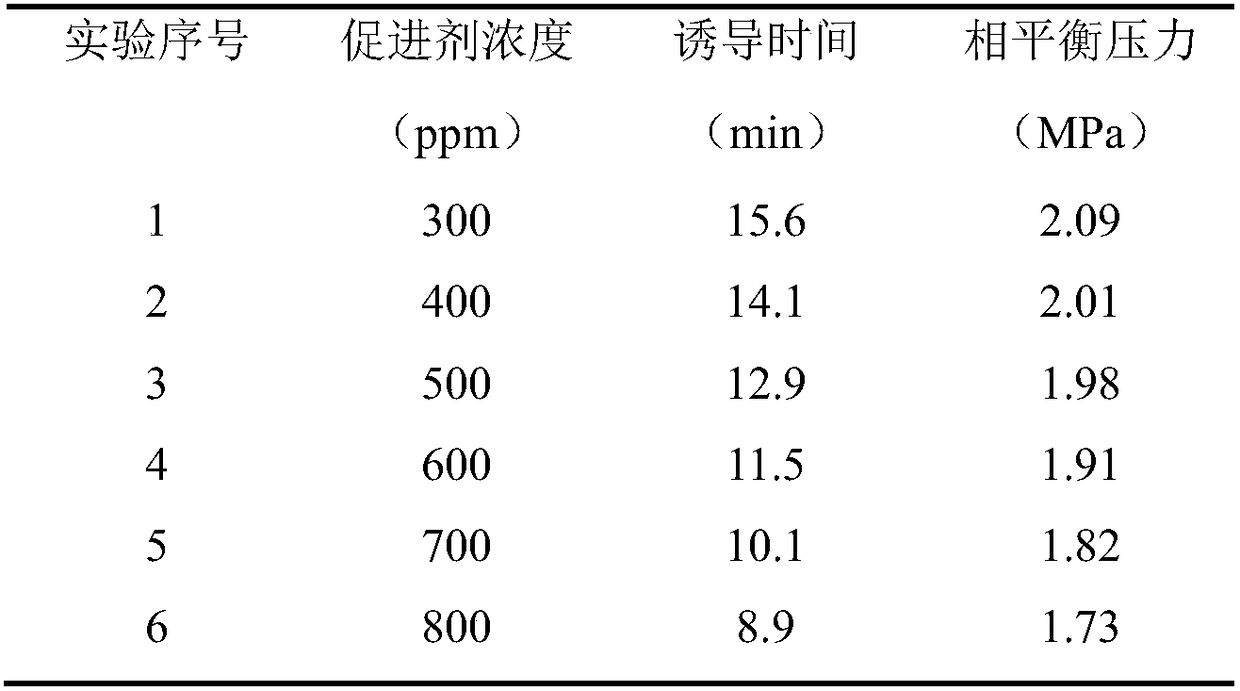

[0035] The selected surfactant ratio is 7% phosphatidylethanolamine + 12% hexan, and the experimental gas is CO 2 , the accelerator concentration in the aqueous solution is 300-800ppm, and the temperature is 280K. Experiments are carried out with the above method, and the experimental data are shown in Table 1.

[0036] Table 1 Experimental results

[0037]

Embodiment 2

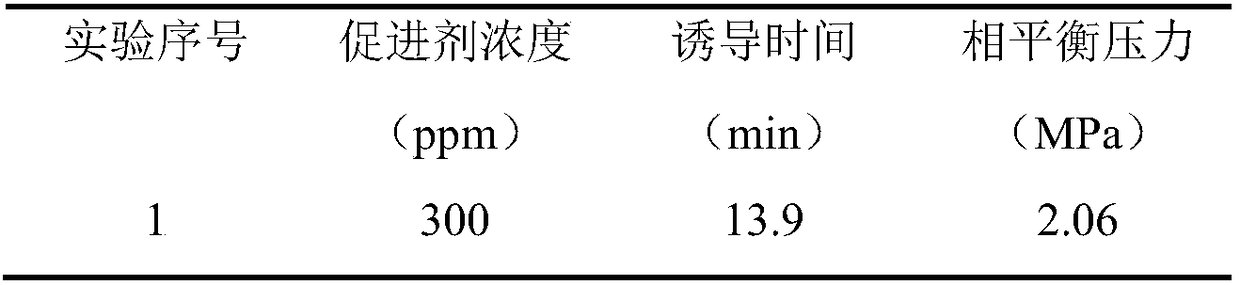

[0039] The selected surfactant ratio is 9% phosphatidylethanolamine + 13% hexan, and the experimental gas is CO 2 , the accelerator concentration in the aqueous solution is 300-800ppm, and the temperature is 280K. Experiments are carried out with the above method, and the experimental data are shown in Table 2.

[0040]Table 2 Experimental results

[0041]

[0042]

Embodiment 3

[0044] The selected surfactant ratio is 11% phosphatidylethanolamine + 15% hexan, and the experimental gas is CO 2 , the accelerator concentration in the aqueous solution is 300-800ppm, and the temperature is 280K. Experiments are carried out with the above method, and the experimental data are shown in Table 2.

[0045] Table 3 Experimental results

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com