Method for adjusting phase change temperature of solid-liquid phase change material

A technology of phase transition temperature and solid-liquid phase transition, which is applied in heat exchange materials, chemical instruments and methods, ocean energy power generation, etc. , Nanoparticle instability and other problems, to achieve the effect of shortening the complete melting time, reducing the complete melting time, and small phase change volume change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

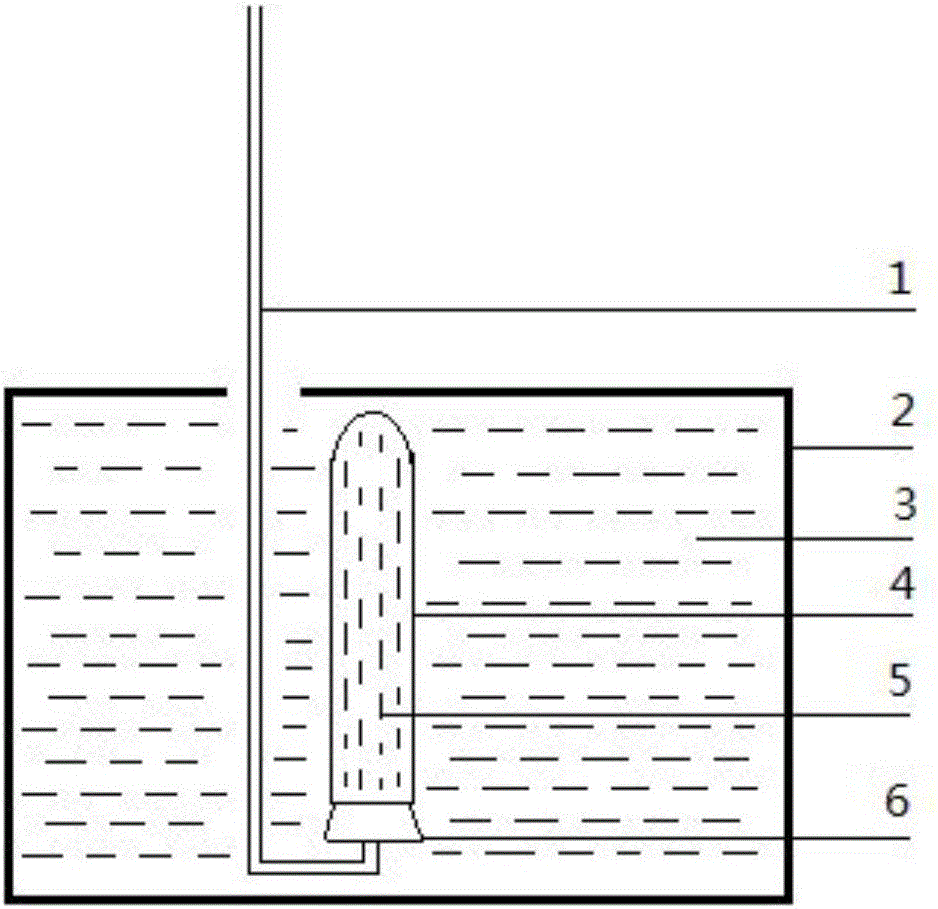

Image

Examples

Embodiment 1

[0045] Hexadecane is used as a one-component solid-liquid phase change material, the phase transition temperature is 17.4°C, the phase transition volume change rate is 10.5%, and the time for complete melting in the temperature range of 5-19°C is 149 minutes.

Embodiment 2

[0047] Hexadecane is used as a one-component solid-liquid phase change material, the phase transition temperature is 17.4°C, the phase transition volume change rate is 10.5%, and the time for complete melting in the temperature range of 5-25°C is 30 minutes.

Embodiment 3

[0049] Hexadecane is used as a one-component solid-liquid phase change material, the phase transition temperature is 17.4°C, the phase transition volume change rate is 10.5%, and the time for complete melting in the temperature range of 5-23°C is 37 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com