InP quantum dot and preparation method thereof

A technology of quantum dots and precursors, applied in the field of InP quantum dots and their preparation, can solve the problems of low luminous efficiency, low color purity, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] As described in the background technology, InP quantum dots in the prior art have low luminous efficiency, poor stability and low color purity. In order to solve this problem, a typical implementation of the present application provides a method for preparing InP quantum dots. The preparation method includes: step S1, using the first InP core and InP nano clusters to prepare a second InP core; step S2, using the second InP core as the core, making Zn precursor, Se precursor and optional S precursor Formed on the surface of the second InP core by epitaxial growth method containing ZnSe x S 1-x Or ZnSe / ZnS shell, get InP / ZnSe x S 1-x Quantum dots or InP / ZnSe / ZnS quantum dots, where 0<x≤1.

[0031] When using the first InP core and InP nanoclusters to prepare the second InP core, the small particle clusters of InP nanoclusters decompose rapidly and diffuse and grow on the large particle first InP core. amount, the amount of cluster solution added, reaction temperature ...

Embodiment 1

[0045] Synthesis of InP nanoclusters:

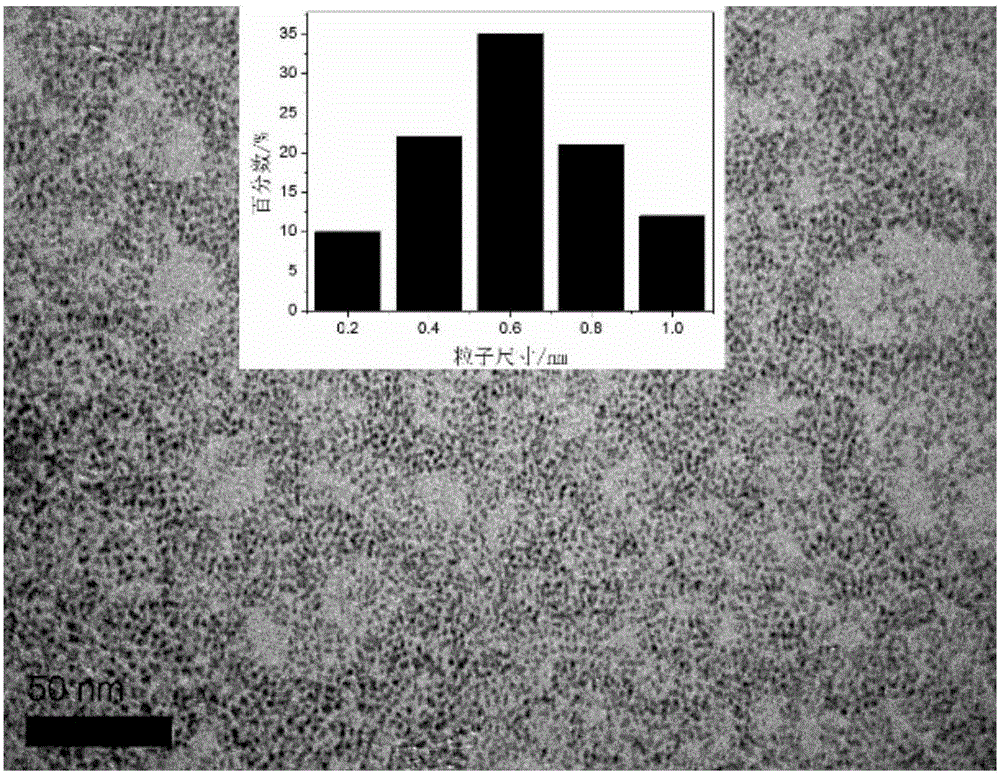

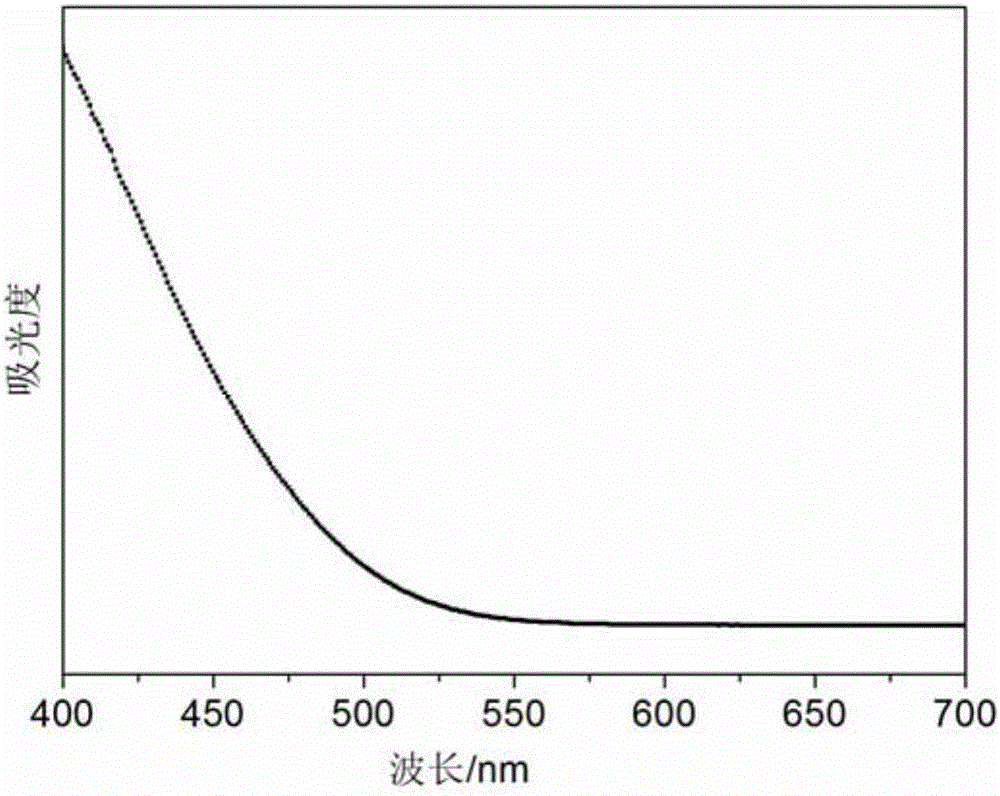

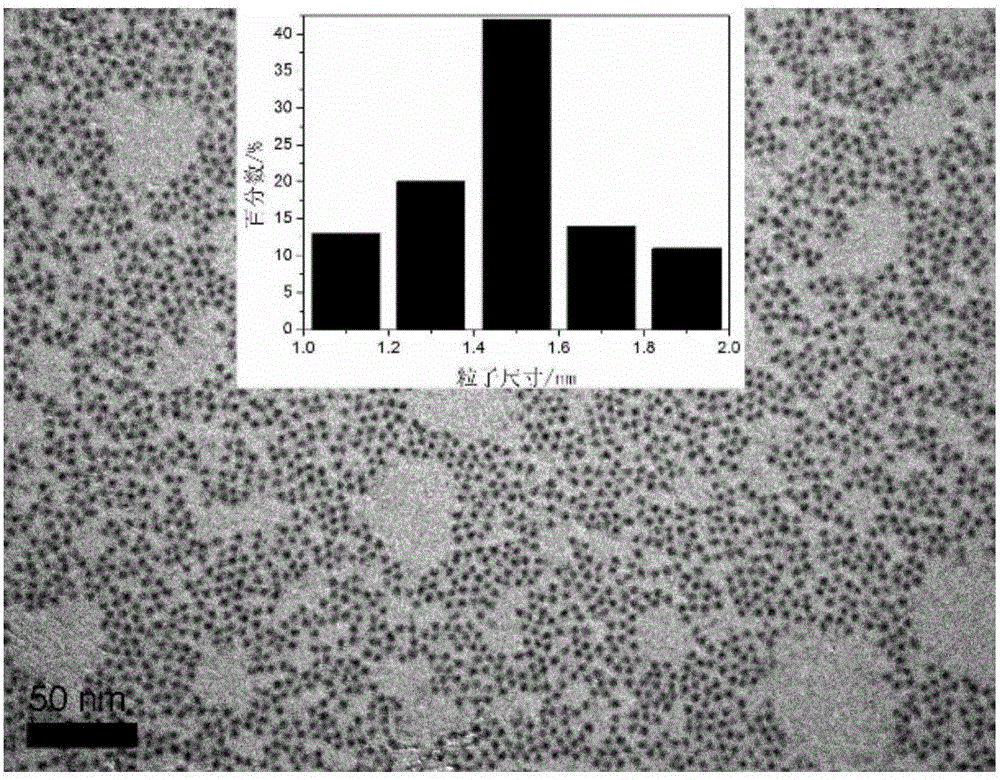

[0046] Add 0.13mmol In(MA) 3 (indium myristate), 0.1mmol dodecanoic acid and 2.0g isotriaxane join in the 50mL three-necked flask, and this three-necked flask is placed under N 2 Heating to 140° C. under exhaust state to form the third mixed liquid. After stabilizing at 140°C for 10min, the temperature of the third mixed solution was lowered to 90°C, and then the second P precursor reactant composed of 0.045mmol TMS-P (tri(trimethylsilyl)phosphine) and 0.045mmol tributylphosphine The second reaction system was formed by rapidly injecting into the third mixed solution at 90° C., and the second reaction system was reacted at 90° C. for 5 minutes to obtain a fourth mixed solution containing InP nanoclusters. Carry out TEM detection and UV test to the InP nanocluster in the 4th mixed solution, wherein TEM image and particle size distribution histogram and UV image are as follows respectively figure 1 and figure 2 shown.

[0047] Synthe...

Embodiment 2

[0052] Synthesis of InP nanoclusters:

[0053] 0.1mmol In(Ac) 3 (indium acetate), 0.3mmol tetradecanoic acid and 1.5g n-eicosane join in the 50mL three-necked flask, and this three-necked flask is placed under N 2 Heating to 100°C in the exhaust state to form the third mixed liquid. After stabilizing at 100°C for 10min, the temperature of the third mixed solution was lowered to 25°C, and then the second P precursor reactant composed of 0.033mmol TMS-P (tris(trimethylsilyl)phosphine) and 0.033mmol trioctylphosphine Quickly injected into the third mixed solution at 25° C. to form a second reaction system, and reacted the second reaction system at 25° C. for 5 minutes to obtain a fourth mixed solution containing InP nanoclusters.

[0054] Synthesis of the second InP core

[0055] Add 0.045mmol In(MA) 3 (indium myristate), 0.05mmol dodecanoic acid and 6.0g octadecene join in the 100mL three-necked flask, and this three-necked flask is placed under N 2 Heating to 150° C. under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com