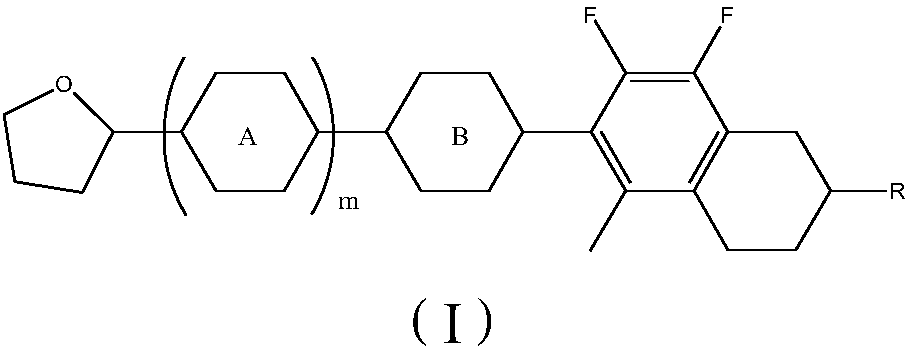

A 7,8-difluoro-5-methyl-1,2,3,4-tetrahydronaphthalene liquid crystal compound and its preparation method and application

A liquid crystal compound, tetralin technology, applied in chemical instruments and methods, liquid crystal materials, organic chemistry, etc., can solve the problems of small wavelength dependence of incident light in the liquid crystal layer, narrow viewing angle, low contrast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The structural formula of the liquid crystal compound provided in this embodiment is:

[0067]

[0068] As another technical solution, when ring B is 1,4-cyclohexylene, that is, when the structure of the liquid crystal compound is as shown in general formula III,

[0069] The synthetic route is as follows:

[0070]

[0071] It includes the following steps:

[0072] (1) Metallization reaction with organolithium reagent, and then with Response, get

[0073] (2) By reacting with boron trifluoride ether and triethylsilane to obtain

[0074] Among them, the R, m, and ring A in the compound involved in each step correspond to the groups represented by R, m and the ring A in the resulting liquid crystal compound product (ie, general formula I).

[0075] In step 1) of the above method, Organolithium reagent and The molar ratio of feeding materials is 1.0~3.0:1.0~3.0:1, and the reaction temperature is -60~-100℃;

[0076] Wherein, the organolithium reagent is selected from one or more...

specific Embodiment approach

[0094] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0095] The raw materials can be obtained from open commercial channels unless otherwise specified.

[0096] According to conventional detection methods in the field, various performance parameters of the liquid crystal compound are obtained by linear fitting, wherein the specific meaning of each performance parameter is as follows:

[0097] △n represents optical anisotropy (25°C); △ε represents dielectric anisotropy (25°C, 1000Hz); γ1 represents rotational viscosity (mPa.s, 25°C).

[0098] Example 1

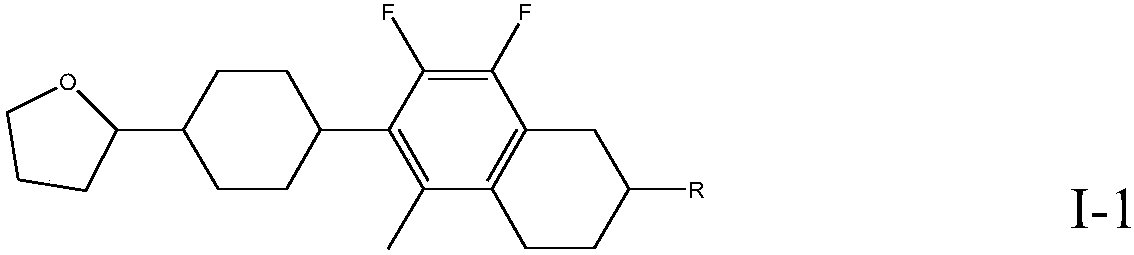

[0099] The structural formula of the liquid crystal compound provided in this embodiment is:

[0100]

[0101] The synthetic route to prepare compound LC-01 is as follows:

[0102]

[0103] Specific steps are as follows:

[0104] (1) Synthesis of compound LC-01-1:

[0105] Under the protection of nitrogen, add 23.8g of 2-butyl 7,8-difluoro-5-methyl-1,2,3,4-tetrahyd...

Embodiment 2

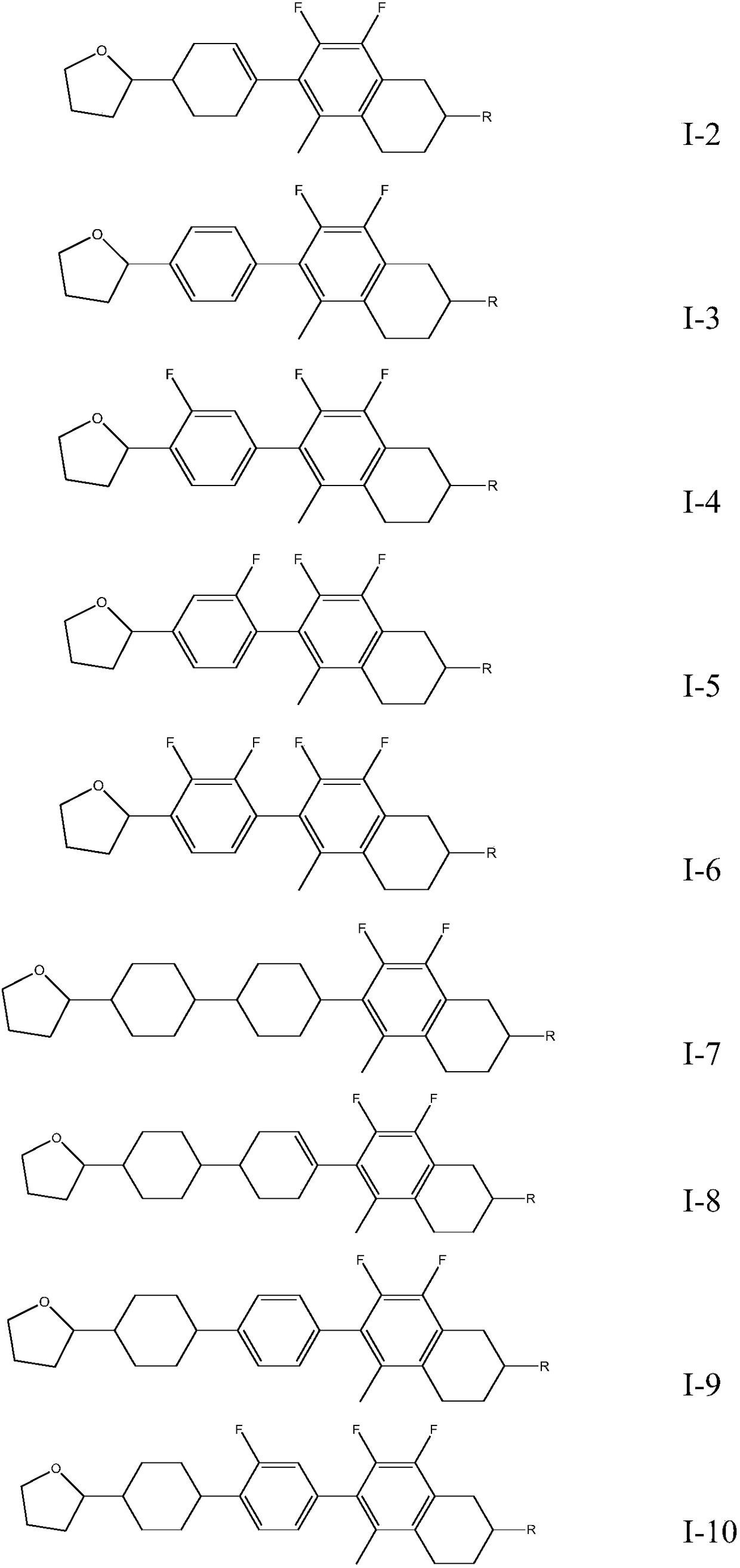

[0111] According to the technical solution of Example 1, the following liquid crystal compounds can be synthesized by simply replacing the corresponding raw materials without changing any substantial operations.

[0112]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com