Preparation method of novel corrosion-resisting zinc cathode plate

A cathode plate, corrosion-resistant technology, applied in the field of preparation of new corrosion-resistant zinc cathode plate, can solve the problems of complex operation process, easy to be corroded, not clear enough, etc., achieve simple preparation process, reduce adhesion, increase anti-F performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

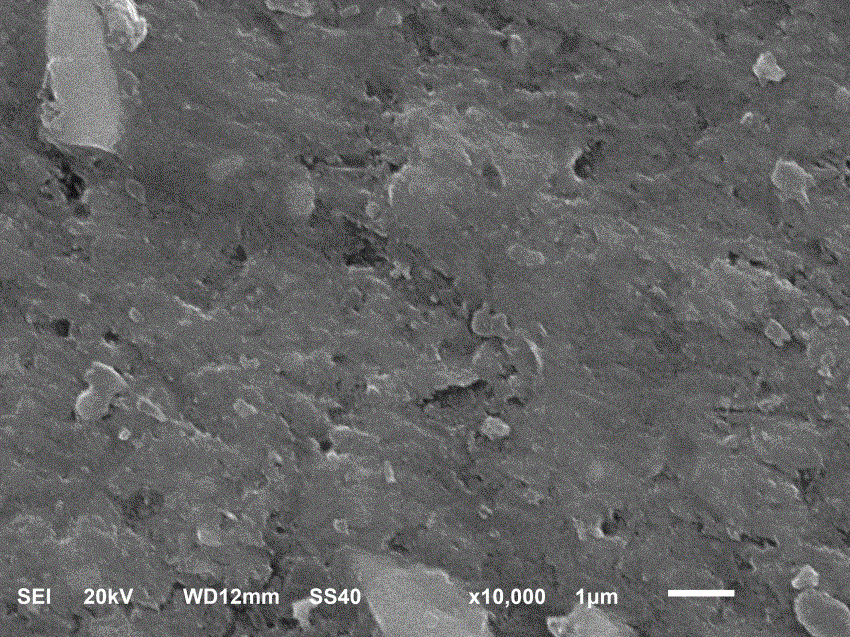

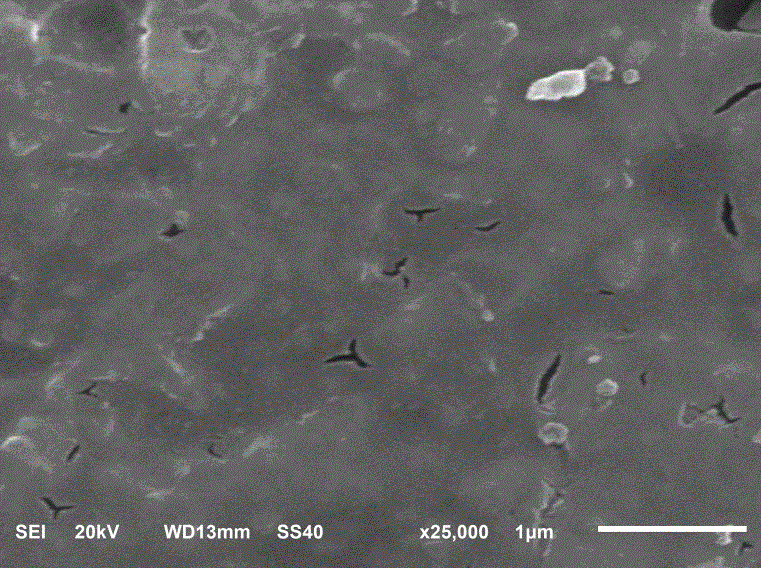

Image

Examples

Embodiment 1

[0043] Step A, pretreatment process: After polishing the common cathode plate, put it into a sulfuric acid solution with a volume percentage concentration of 50g / L and soak it at a temperature of 75°C for 1 hour, then perform alkali washing, water washing, polishing and ultrasonic washing to obtain Pretreat cathode plates.

[0044] Step B, oxidation process: oxidize the pretreated cathode plate obtained in step A in an acidic oxidation tank with hydrogen peroxide, a sulfuric acid solution with a volume percentage concentration of 120g / L, an oxidation temperature of 95°C, an oxidation time of 3 hours, and wash with water Afterwards, an oxidized cathode plate is obtained.

[0045] Step C, sealing process: put the oxidized cathode plate obtained in step B into a sulfuric acid solution with a volume percentage concentration of 50 g / L, a mass percentage concentration of potassium permanganate of 20%, a sealing temperature of 70°C, and a sealing time of 5 hours , to obtain a closed...

Embodiment 2

[0049] Step A, pretreatment process: After polishing the common cathode plate, put it into a sulfuric acid solution with a volume percentage concentration of 100g / L and soak it at a temperature of 50°C for 3 hours, then perform alkali washing, water washing, polishing and ultrasonic washing to obtain Pretreat cathode plates.

[0050] Step B, oxidation process: oxidize the pretreated cathode plate obtained in step A in an acidic oxidation tank with hydrogen peroxide, a sulfuric acid solution with a volume percentage concentration of 180g / L, an oxidation temperature of 80°C, an oxidation time of 6 hours, and wash with water Afterwards, an oxidized cathode plate is obtained.

[0051] Step C, sealing process: put the oxidized cathode plate obtained in step B into a sulfuric acid solution with a volume percentage concentration of 120 g / L, a mass percentage concentration of potassium permanganate of 15%, a sealing temperature of 90°C, and a sealing time of 3 hours , to obtain a clo...

Embodiment 3

[0055] Step A, pretreatment process: After polishing the common cathode plate, put it into a sulfuric acid solution with a volume percentage concentration of 80g / L and soak it at a temperature of 65°C for 2 hours, then perform alkali washing, water washing, polishing and ultrasonic washing to obtain Pretreat cathode plates.

[0056] Step B, oxidation process: oxidize the pretreated cathode plate obtained in step A in an acidic oxidation tank with hydrogen peroxide, a sulfuric acid solution with a concentration of 150 g / L by volume, an oxidation temperature of 85° C., and an oxidation time of 4 hours. Wash with water Afterwards, an oxidized cathode plate is obtained.

[0057] Step C, sealing process: put the oxidized cathode plate obtained in step B into a sulfuric acid solution with a volume percentage concentration of 80g / L, the mass percentage concentration of potassium permanganate is 17%, the sealing temperature is 80°C, and the sealing time is 4 hours , to obtain a close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com