Composite type room temperature magnetic refrigeration system and direction control valve thereof

A directional control valve, compound technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of switching noise, cumbersome overall structure, loud noise, etc., to reduce additional power consumption, compact overall structure, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The invention provides a directional control valve with simple and compact structure, low energy consumption and low noise to replace multiple solenoid valves used in the current composite room temperature magnetic refrigeration system. On this basis, the present invention also provides a composite room temperature magnetic refrigeration system including the directional control valve.

[0049] In order to facilitate a better understanding of the technical solution of the present invention, the specific structure of the composite room temperature magnetic refrigeration system and its directional control valve will now be described in detail with reference to the accompanying drawings.

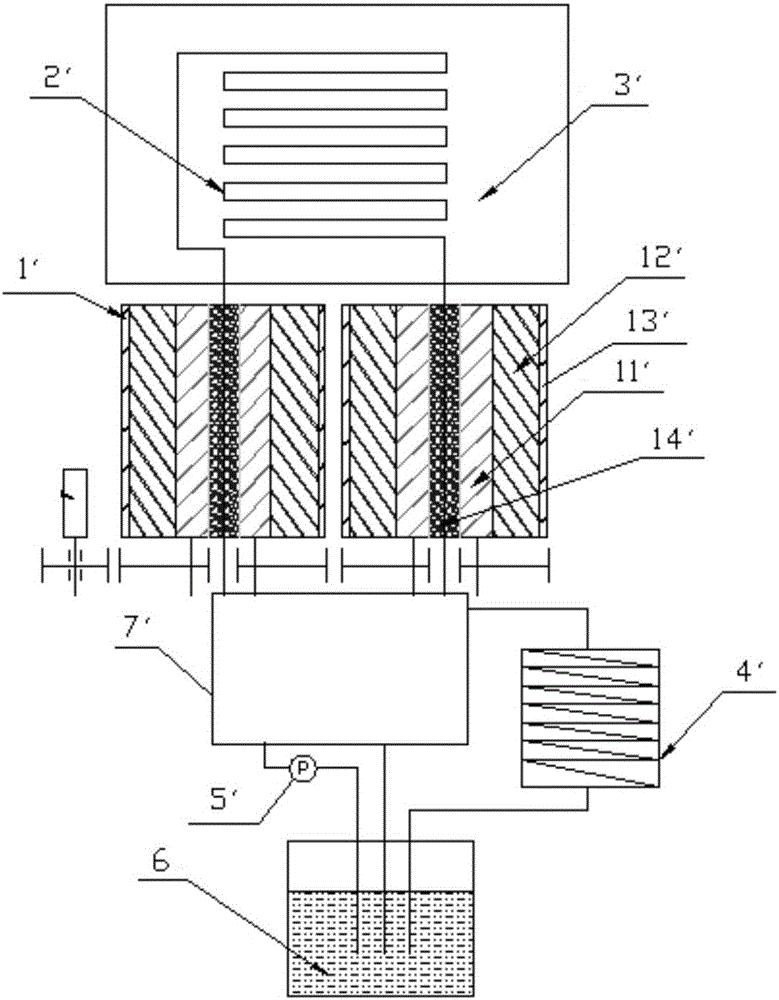

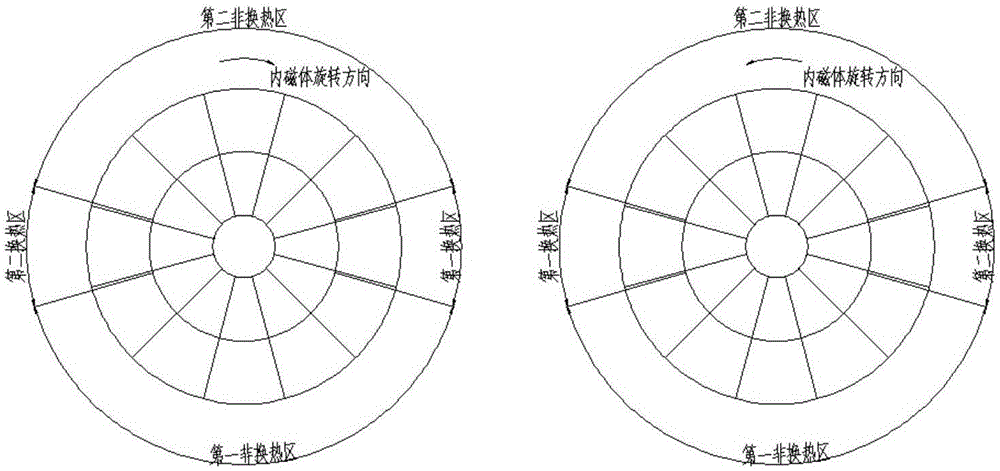

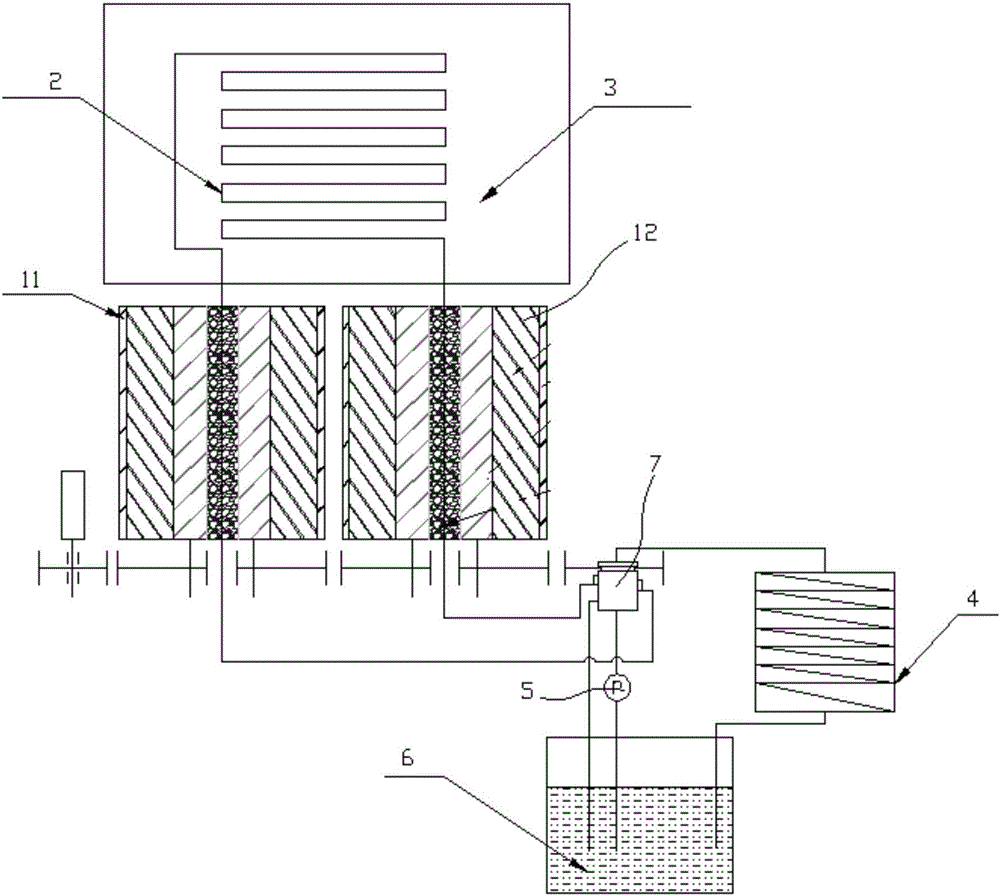

[0050] See image 3 and Figure 4 ,in, image 3 A schematic structural view of the compound room temperature magnetic refrigeration system provided by the present invention is shown, Figure 4 A schematic structural view of a specific embodiment of the directional control valve provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com