High-temperature solid micro-powder residual heat boiler

A high-temperature solid waste heat boiler technology, applied in the field of solid waste heat boilers, can solve the problems of high dust content in heat loss gas, environmental pollution, etc., and achieve uniform heat transfer, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

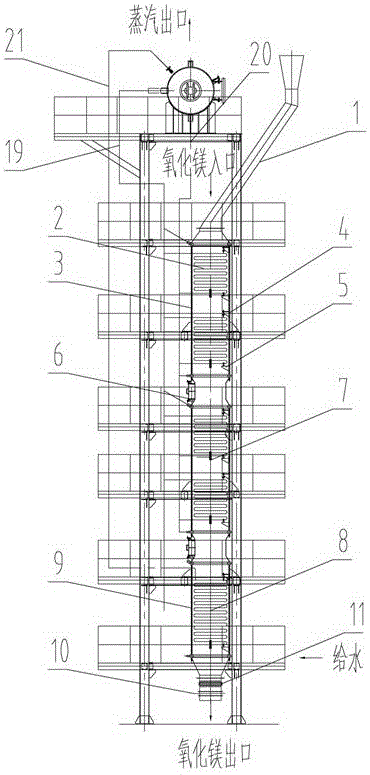

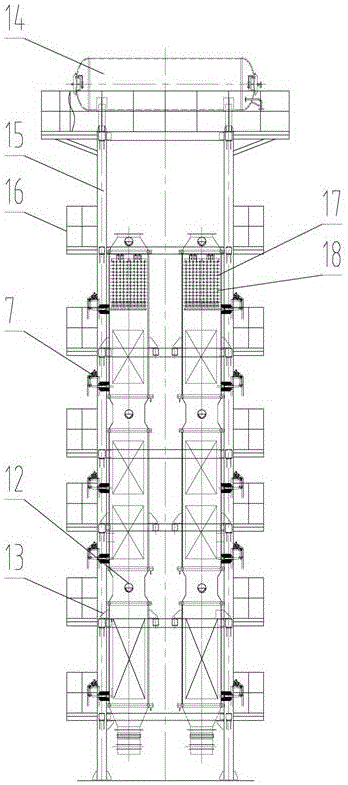

[0010] Specific description will be given below in conjunction with the accompanying drawings.

[0011] Such as figure 1 , 2 As shown, the high-temperature solid micro-powder waste heat boiler consists of material inlet 1, evaporator 2, water wall 3, serpentine tube heating surface hanging device 4, serpentine tube heating surface support device 5, expansion device 6, mechanical vibrator 7 , economizer 8, wall water heater 9, feeding control valve 10, material outlet 11, material level monitoring device 12, ear support 13, steam-water separator 14, supporting steel frame 15, platform 16, serpentine tube heating surface 17 and membrane sheet 18, the angle between the material inlet 1 pipe and the horizontal direction is not less than 45 degrees, the water wall 3 and the wall water heater 10 are in turn below the material inlet 1, and the water wall 3 is equipped with an evaporator 2 inside. An economizer 8 is arranged inside the water heater 9, and the water wall 3 and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com