Digital measuring device and method for shaft section area

A digital measurement and shaft technology, which is applied to measurement devices, section drawing, surveying and mapping, and navigation, etc., can solve the problems of easy data loss, difficulty in re-measurement, and high frequency, so as to achieve short process time occupation, simple re-measurement and verification, and easy re-measurement. The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

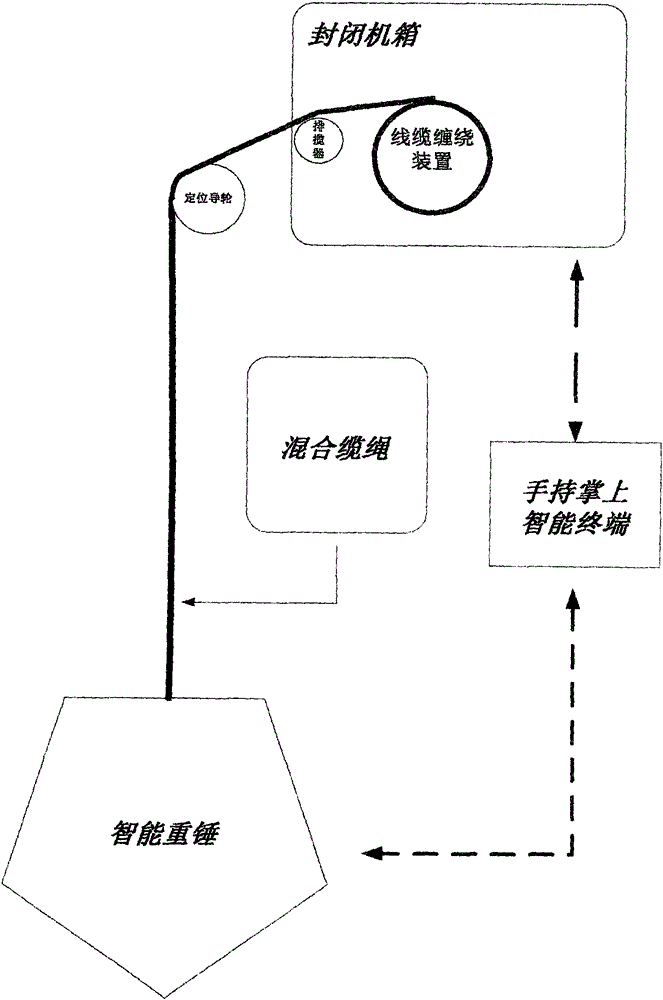

[0036] A digital measuring device for shaft section, comprising

[0037] A box-type electric winch,

[0038] An intelligent weight, which is connected with the box-type electric winch through a hybrid cable, is used to measure the radius of any depth in the shaft;

[0039] A hand-held intelligent terminal is connected to the box-type electric winch and the intelligent hammer through wireless means to control the start, operation, positioning, data measurement, recording, display, judgment and alarm of the intelligent hammer.

[0040] Further, the box-type electric winch includes a box body and a hybrid cable, and the box body is provided with a puller, a cable winding device, a depth counter, a variable speed motor, a controller, a data recorder and a data display screen,

[0041] One end of the hybrid cable is connected to the cable winding device through the puller, the cable winding device is connected to the deceleration motor drive, the deceleration motor drive is connec...

specific Embodiment 2

[0059] Roughly the same as the specific embodiment 1, the only difference is

[0060] The handheld intelligent terminal is an iPad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com