Preparation method of ultra-thin BiOCl nano-sheet photocatalyst

A photocatalyst, nanosheet technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

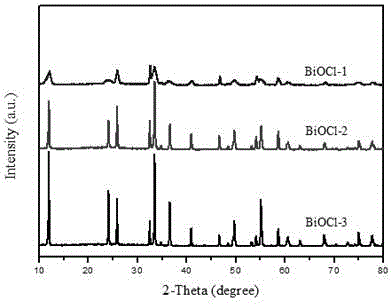

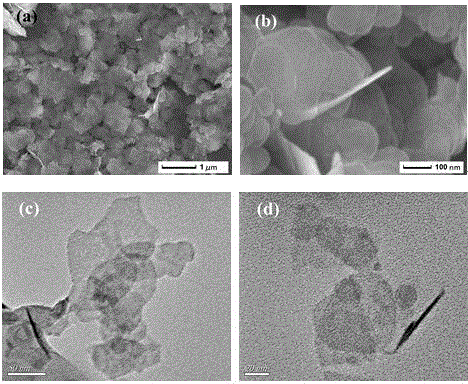

Embodiment 1

[0025] Take 1-hexadecyl-3-methylimidazole chloride as the step of preparing photocatalyst BiOCl nanosheets as chlorine source:

[0026] Take 1 mmol of bismuth nitrate pentahydrate, add 1 mL of glacial acetic acid and 9 mL of deionized water to make solution A, take 1 mmol of 1-hexadecyl-3-methylimidazole chloride and add 10 mL of absolute ethanol to make solution B. Add solution B dropwise to solution A, and stir rapidly. After the dropwise addition, continue to stir for 15-45 minutes, pour the above solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, at 140-160°C React for 12-24 hours. The obtained product is centrifuged, washed three times with deionized water and absolute ethanol, and finally dried at 30-60°C.

Embodiment 2

[0028] Take 1-hexadecyl-3-methylimidazole chloride as the step of preparing photocatalyst BiOCl nanosheets as chlorine source:

[0029] Take 1 mmol of bismuth nitrate pentahydrate, add 1 mL of glacial acetic acid and 9 mL of deionized water to make solution A, take 1 mmol of 1-hexadecyl-3-methylimidazole chloride and add 10 mL of absolute ethanol to make solution B. Add solution B dropwise to solution A, and stir rapidly. After the dropwise addition, continue stirring for 15 minutes, pour the above solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, and react at 140°C for 12 hours. The obtained product was centrifuged, washed three times with deionized water and absolute ethanol, and finally dried at 50°C.

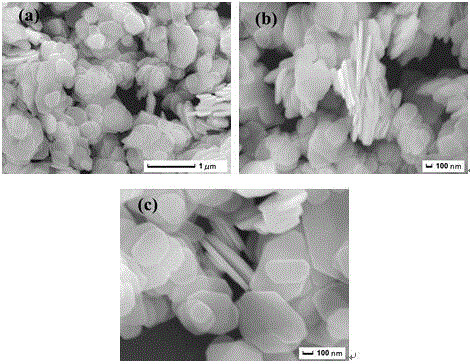

Embodiment 3

[0031] Take 1-hexadecyl-3-methylimidazole chloride as the step of preparing photocatalyst BiOCl nanosheets as chlorine source:

[0032] Take 1 mmol of bismuth nitrate pentahydrate, add 1 mL of glacial acetic acid and 9 mL of deionized water to make solution A, take 1 mmol of 1-hexadecyl-3-methylimidazole chloride and add 10 mL of absolute ethanol to make solution B. Add solution B dropwise to solution A, and stir rapidly. After the dropwise addition, continue stirring for 30 minutes, pour the above solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner, and react at 140°C for 18 hours. The obtained product was centrifuged, washed three times with deionized water and absolute ethanol, and finally dried at 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com