Double-phase rotating stream separation system

A flow separation and phase swirl technology, which is applied to swirl devices and devices whose axial directions can be reversed. , the effect of eliminating short-circuit flow and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

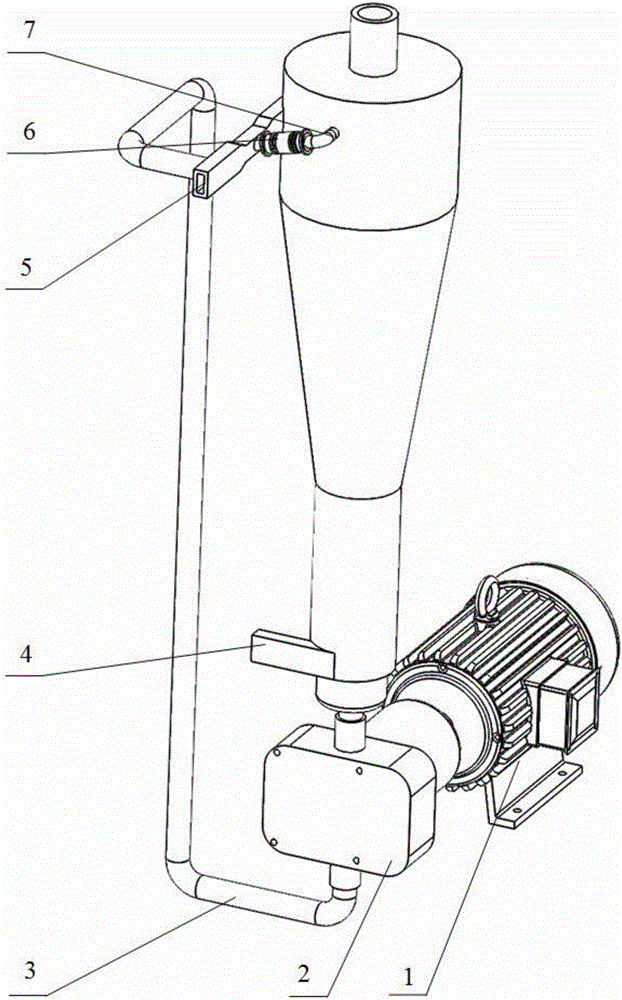

[0028] Depend on figure 1 , 2 and Figure 4 As shown, this kind of two-phase cyclone separation system is composed of a motor, a booster pump, a long circulation pipeline, a short circulation pipeline, a swirl fluid and a one-way valve after connection;

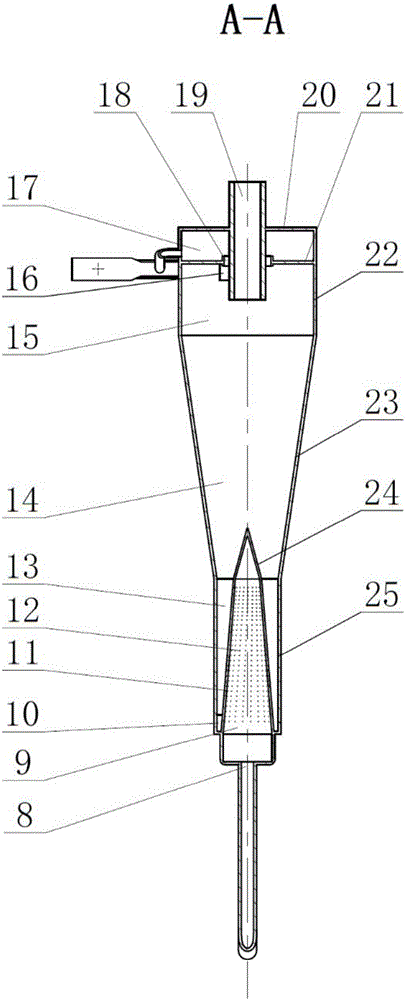

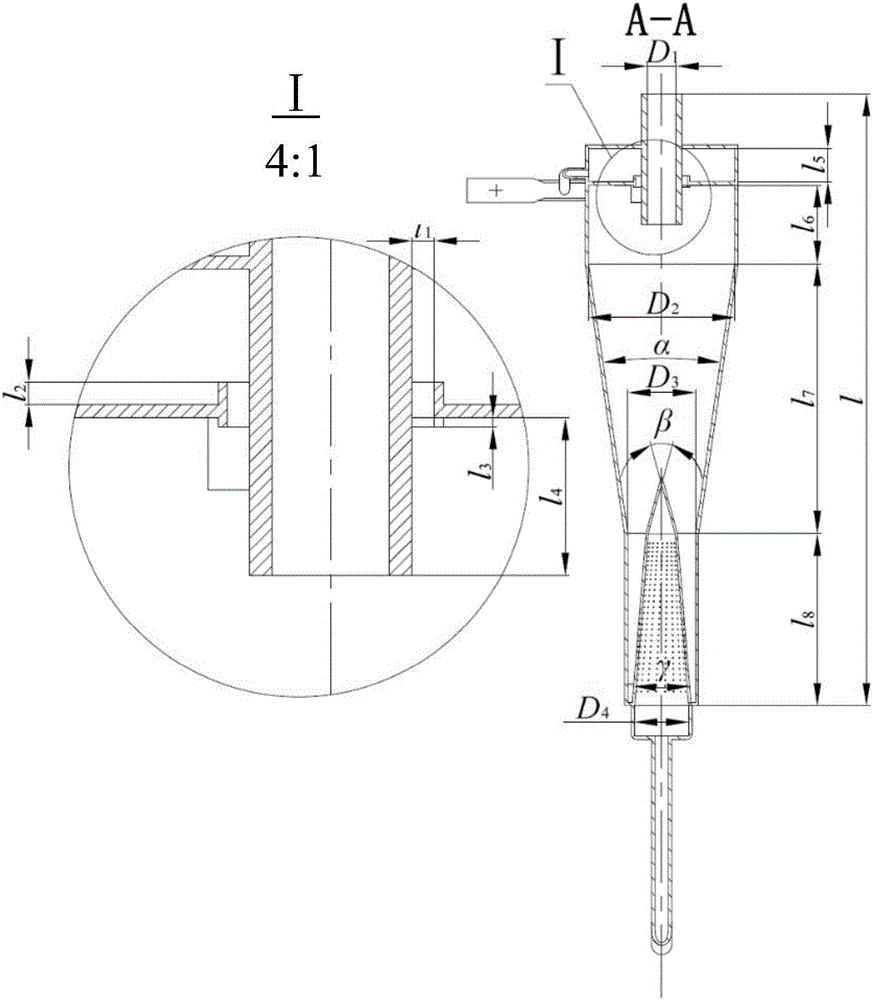

[0029] Wherein, the swirl body is composed of a swirl chamber cylinder, a separation cone cone, an external underflow section cylinder, and an underflow pipe with a diameter-reducing step connected in sequence;

[0030]The top end of the swirl chamber is closed by a first end cap, a second end cap is fixed below the first end cap, and an inner overflow is fixed through the center of the first end cap and the second end cap. pipe, the central hole wall of the second end cover does not touch the outer pipe wall of the inner overflow pipe, and an annular space is formed between the two, and the annular space forms an annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com