Reflective insulation nano-modified quartz sand and preparation method thereof

A nano-modification, quartz sand technology, applied in chemical instruments and methods, reflective/signal coatings, inorganic pigment treatment, etc. The effect of easy promotion and saving transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

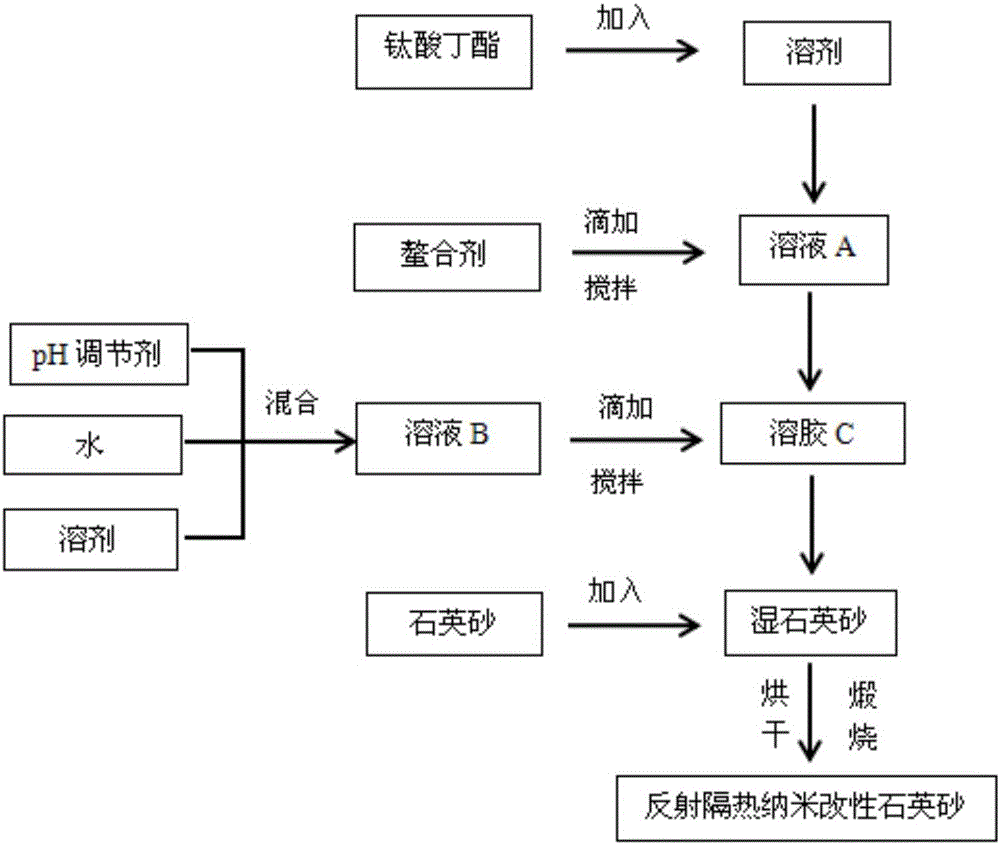

[0029] A method for preparing reflective heat-insulating nano-modified quartz sand: comprising the following steps:

[0030] Step 1. Add butyl titanate into the solvent, stir to make it fully dissolved, then add the chelating agent dropwise while stirring, and stir for 40-180min to prepare solution A;

[0031] Step 2, adding the pH adjuster and water into the solvent, stirring and mixing evenly to obtain solution B;

[0032] Step 3. Add solution B dropwise to solution A while stirring, continue stirring for 30-90 minutes after the addition, and leave to age for 10-48 hours after stirring to obtain sol C;

[0033] Step 4: Add quartz sand to sol C, stir to make it fully wet, let stand for 5-24 hours, filter and dry the quartz sand at 60-90°C for 30-90min, then calcinate at 450-750°C for 2- 8h, after annealing and cooling, the product is reflective heat insulation nano-modified quartz sand.

Embodiment 1

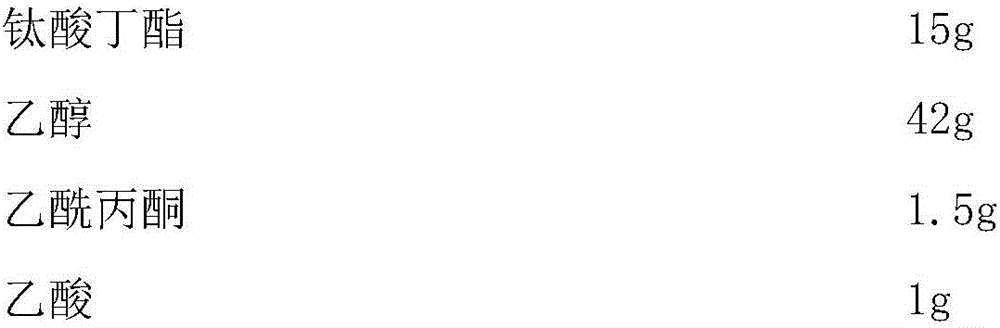

[0036] A reflective heat-insulating nano-modified quartz sand, which consists of the following raw materials:

[0037]

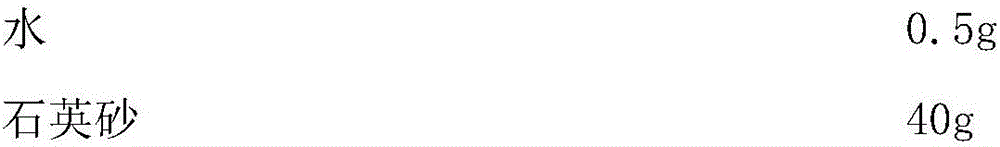

[0038]

[0039] The above raw materials are 100g in total.

[0040] Prepared according to the following steps:

[0041] Step 1. Add 15g of butyl titanate into 30g of ethanol, stir to make it fully dissolved, then add 1.5g of acetylacetone dropwise while stirring, and stir for 90min to obtain solution A;

[0042] Step 2: Add 1g of acetic acid and 0.5g of water into 12g of ethanol, stir and mix evenly to prepare solution B;

[0043] Step 3. Add solution B dropwise to solution A while stirring, continue to stir for 60 minutes after the addition, and leave to age for 24 hours after stirring to obtain Sol C;

[0044] Step 4: Add 40g of quartz sand to sol C, stir to make it fully wet, let it stand for 12 hours, filter and dry the quartz sand at 80°C for 45 minutes, and then calcinate at 650°C for 5 hours, after annealing and cooling, the product is reflectiv...

Embodiment 2

[0047] A reflective heat-insulating nano-modified quartz sand, which consists of the following raw materials:

[0048]

[0049] The above raw materials are 100g in total.

[0050] Prepared according to the following steps:

[0051] Step 1. Add 10 g of butyl titanate into 30 g of isopropanol, stir to make it fully dissolve, then add 2 g of diethanolamine dropwise while stirring, and stir for 45 minutes to obtain solution A;

[0052] Step 2: Add 0.5g of hydrochloric acid and 0.5g of water into 15g of isopropanol, stir and mix evenly to prepare solution B;

[0053] Step 3. Add solution B dropwise to solution A while stirring, continue to stir for 90 minutes after the addition, and leave to age for 30 hours after stirring to obtain Sol C;

[0054] Step 4: Add 42g of quartz sand to sol C, stir to make it fully wet, let it stand for 15 hours, filter and dry the quartz sand at 70°C for 60 minutes, and then calcinate at 700°C for 3 hours, after annealing and cooling, the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com