A kind of purification device and purification method of raw material for crystal growth by gas phase method

A technology of crystal growth and gas phase method, applied in the directions of crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of residual impurities and incomplete purification, and achieve effective separation, rapid and effective purification, and enhanced controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Gas phase method CdS raw material purification method, the implementation steps are as follows:

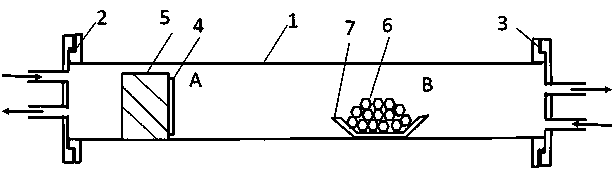

[0022] 1. Use such as figure 1 In the shown double-flange raw material purification device, the cylindrical support structure 5 and the substrate 4 are placed at the A end of the quartz tube 1, and the CdS raw material 6 is placed in the small boat 7 at the B end of the quartz tube 1, and the distance between the small boat 7 and the substrate 4 is 25cm; Use the left flange 2 and the right flange 3 to seal the openings at both ends of the quartz tube 1, and then place the purification device as a whole horizontally in a dual-temperature zone resistance furnace (the model of the dual-temperature zone resistance furnace is PVT-TC -01).

[0023] 2. After the device is sealed, the system is vacuumed, and the air inlets of the A and B flanges at both ends of the quartz tube are kept closed, and the air outlet is opened to vacuum for 20 minutes to remove the air in the quartz tu...

Embodiment 2

[0030] Gas phase ZnSe raw material purification method, the implementation steps are as follows:

[0031] 1. Use such as figure 1 In the shown double-flange raw material purification device, the cylindrical support structure 5 and the substrate 4 are placed at the A end of the quartz tube 1, and the ZnSe raw material 6 is placed in the small boat 7 at the B end of the quartz tube 1, and the distance between the small boat 7 and the substrate 4 is About 25cm; Use the left flange 2 and the right flange 3 to seal the openings at both ends of the quartz tube 1, and then place the purification device as a whole horizontally in a dual-temperature zone resistance furnace (the model of the dual-temperature zone resistance furnace is PVT- TC-01).

[0032] 2. After the device is sealed, the system is vacuumed, and the air inlets of the A and B flanges at both ends of the quartz tube are kept closed, and the air outlet is opened to vacuumize for 20 minutes to remove the air in the chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com