Dyeing auxiliary and preparation method thereof

A technology of dyeing auxiliaries and color-fixing agents, applied in the field of textile dyeing, which can solve the problems of dye waste, affecting the quality of blended textiles, and reducing the brightness of color, etc., to solve uneven dyeing, improve coloring effect, and improve color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

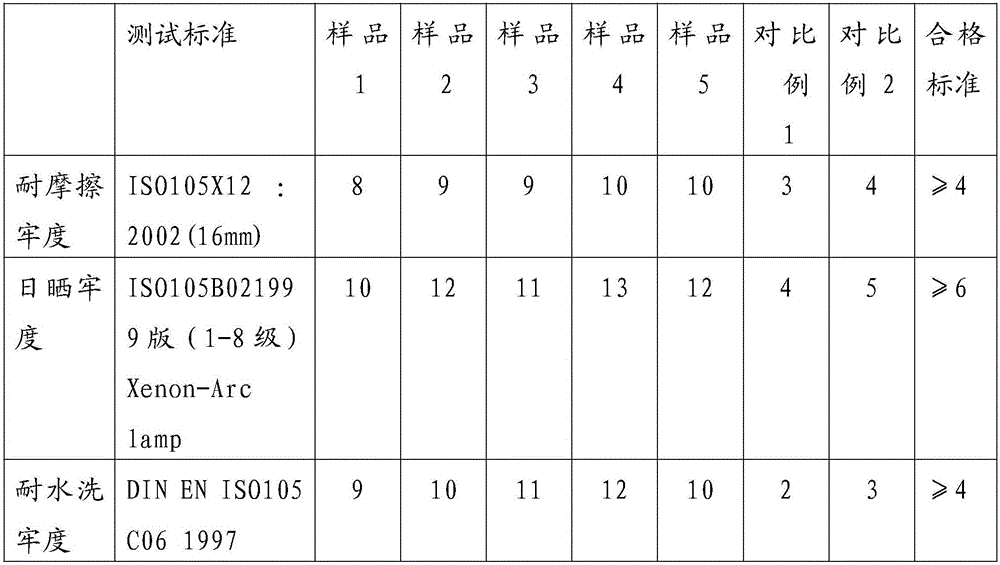

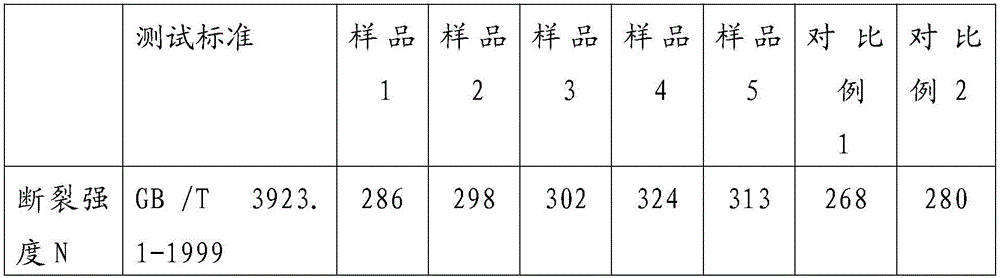

Examples

Embodiment 1

[0021] Preparation of Small Molecule Water

[0022] Take natural fresh water, sterilize and filter, distill and purify, then heat and boil in 80-450Hz, 200-850V pulsed oscillating electric field, and then cool and fill under the condition of 0.2-0.7 atmospheric pressure, that is, the water after filling and sealing The temperature is 18-20°C.

[0023] The cohesion of the above-mentioned small molecular water increases, the surface tension increases, the pH thereof is between 7.3 and 8.2, and the half-width of the water molecular cluster is between 35 and 42 Hz.

Embodiment 2

[0025] A kind of dyeing auxiliary agent, comprises following component according to parts by weight (g):

[0026] 2 parts of chitosan, 1.5 parts of sodium polyacrylate, 4 parts of color fixing agent NFC, 6 parts of leveling agent SE, 3 parts of alkylphenol polyoxyethylene ether, 3 parts of sodium alkyl sulfosuccinate, polyether modified silicone oil 8 parts, 3 parts of polyvinyl alcohol, 1.5 parts of cross-linking agent MH and appropriate amount of small molecule water.

Embodiment 3

[0028] A kind of dyeing auxiliary agent, according to parts by weight (g) comprises following component:

[0029] 3 parts of chitosan, 5 parts of chlorogenic acid, 2.5 parts of sodium polyacrylate, 3.5 parts of color fixing agent NFC, 10 parts of leveling agent SE, 2.5 parts of alkylphenol polyoxyethylene ether, sodium alkyl sulfosuccinate 5 parts, 13 parts of polyether modified silicone oil, 1.8 parts of polyvinyl alcohol, 2.5 parts of crosslinking agent MH and appropriate amount of small molecule water.

[0030] Its preparation method comprises the following steps:

[0031] (1) Weigh chitosan, chlorogenic acid, and polyether modified silicone oil sequentially according to parts by weight, then mix the above three raw materials and add an appropriate amount of small molecule water, stir ultrasonically for 45 minutes, and then mix them under the condition of 1500 rpm Stir for 8h to obtain a suspension;

[0032] (2) Add sodium polyacrylate, color fixing agent NFC, and levelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com