Touch display panel, manufacturing method thereof, and touch display device

A technology for a touch display panel and a manufacturing method, which are applied in the fields of instruments, computing, electrical digital data processing, etc., can solve the problems of the polarizer being easily affected by a humid environment, the problem that the polarizer is not easily affected by moisture, and the process and manufacturing costs are increased. , to avoid being susceptible to moisture, improve the aspect ratio, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

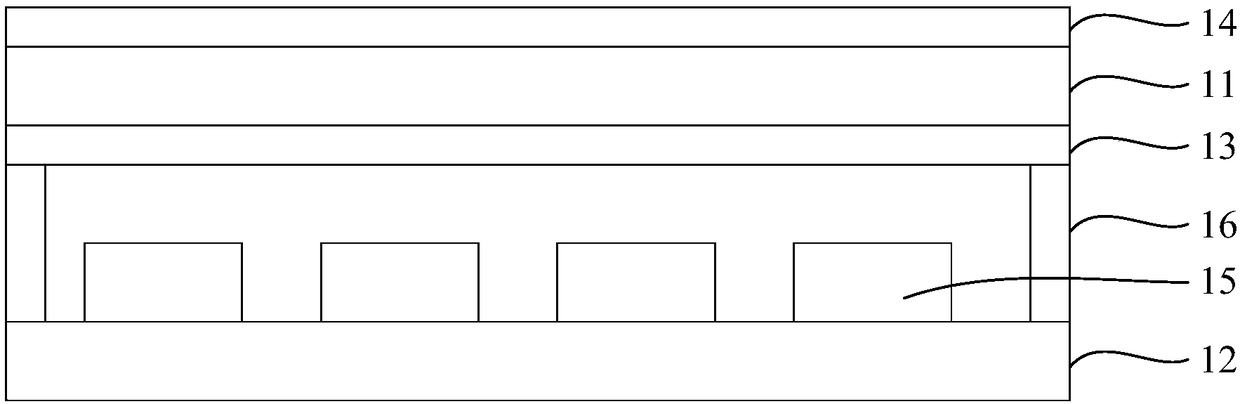

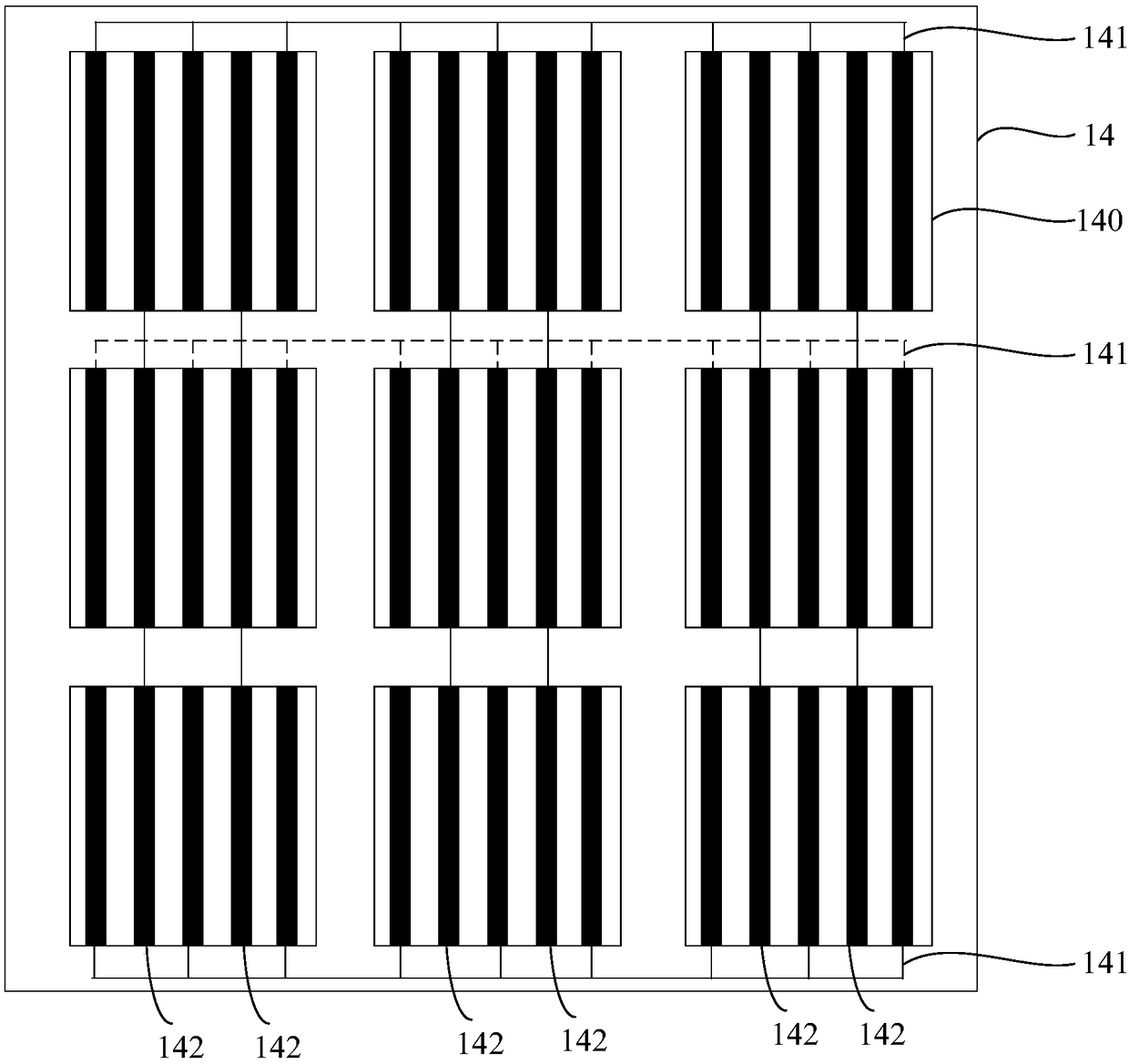

[0038] Please refer to figure 1 and figure 2 , which is a schematic structural diagram of the touch display panel provided in Embodiment 1 of the present invention. Such as figure 1 and figure 2 As shown, the touch display panel includes: a first substrate 11 and a second substrate 12 oppositely arranged, a nano-metal grating 14 located on the first substrate 11 away from the second substrate 12, located on the The organic light-emitting layer 15 on the second substrate 12 close to the first substrate 11 side, and the retardation film 13 between the nano-metal grating 14 and the organic light-emitting layer 15; the retardation film 13 and the organic light-emitting layer 15 The nano-metal grating 14 constitutes a circular polarizer, and the nano-metal grating 14 is divided into at least one mutually conductive grating unit, and the at least one mutually conductive grating unit constitutes a touch sensor.

[0039] In this embodiment, the nano-metal grating 14 is located o...

Embodiment 2

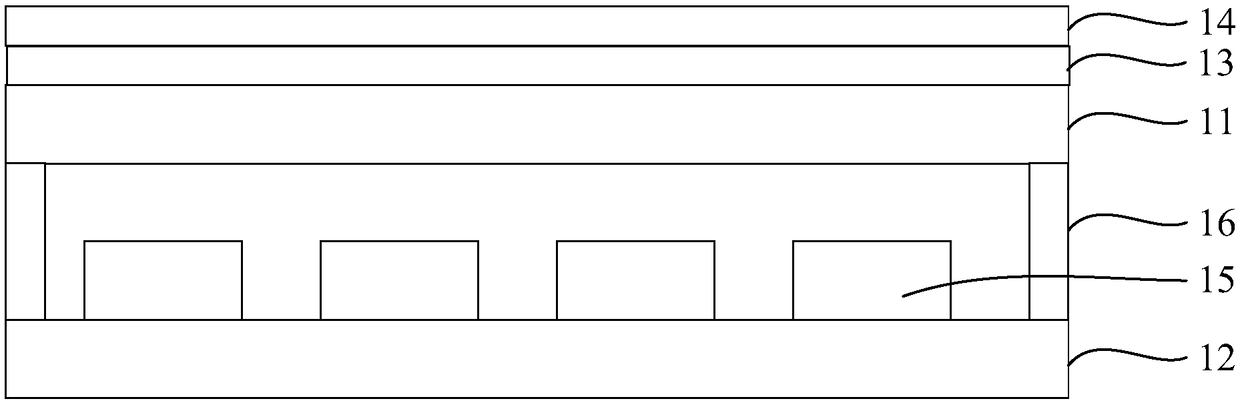

[0048] On the basis of Embodiment 1, the metal nano grating is located on the side of the first substrate close to the second substrate, and the phase difference film is located between the metal nano grating and the organic light-emitting layer .

[0049] Please refer to Figure 4 , which is a schematic structural diagram of the touch display panel provided in Embodiment 2 of the present invention. Such as Figure 4 As shown, the touch display panel includes: a first substrate 21 and a second substrate 22 oppositely arranged, a nano-metal grating 24 located on the first substrate 21 close to the side of the second substrate 22, located on the The organic light-emitting layer 25 on the second substrate 22 close to the first substrate 21 side, the retardation film 23 between the nano-metal grating 24 and the organic light-emitting layer 25; the retardation film 23 and the organic light-emitting layer 23 The nano-metal grating 24 constitutes a circular polarizer, and the nano...

Embodiment 3

[0058] Please refer to Figure 6 , which is a flow chart of the manufacturing method of the touch display panel provided by the third embodiment of the present invention. Such as Figure 6 As shown, the manufacturing method of the touch display panel includes the following steps:

[0059] Step S01: providing a first substrate, forming a nano-metal grating on the first substrate, and the nano-metal grating is composed of at least one mutually conductive grating unit;

[0060] Step S02: providing a second substrate, and forming an organic light-emitting layer on the second substrate;

[0061] Step S03: attaching the side of the second substrate on which the organic light-emitting layer is formed and the side of the first substrate away from the metal nano grating.

[0062] The touch display panel formed according to the manufacturing method of the touch display panel provided in this embodiment is as described in the first embodiment. Please refer to Figure 6 shown, combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com