Modularization photovoltaic device

A photovoltaic device and modular technology, which is applied in the field of modular photovoltaic devices, can solve the problems of inability to realize the instant use of photovoltaic modules, low modularity of photovoltaic systems, and difficulty in moving and transporting at will, so as to save manpower and improve construction efficiency. High, easy to fold and transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

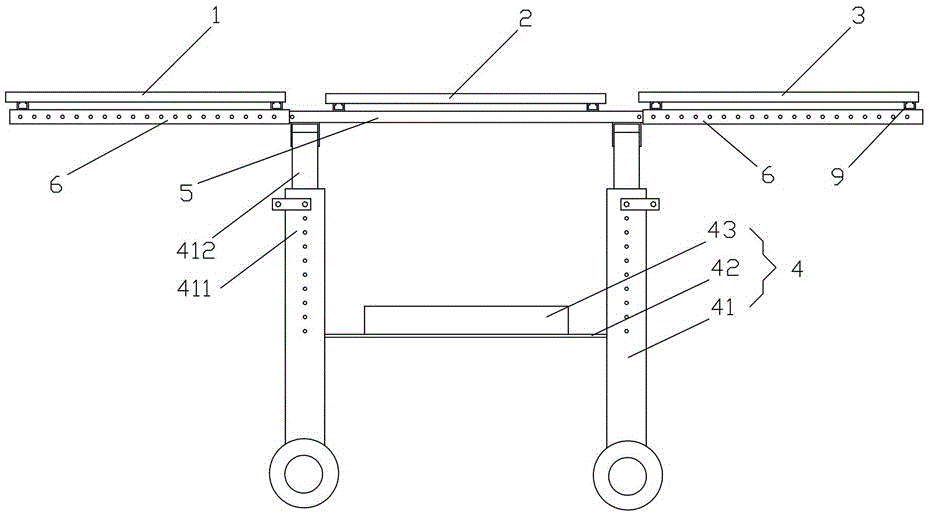

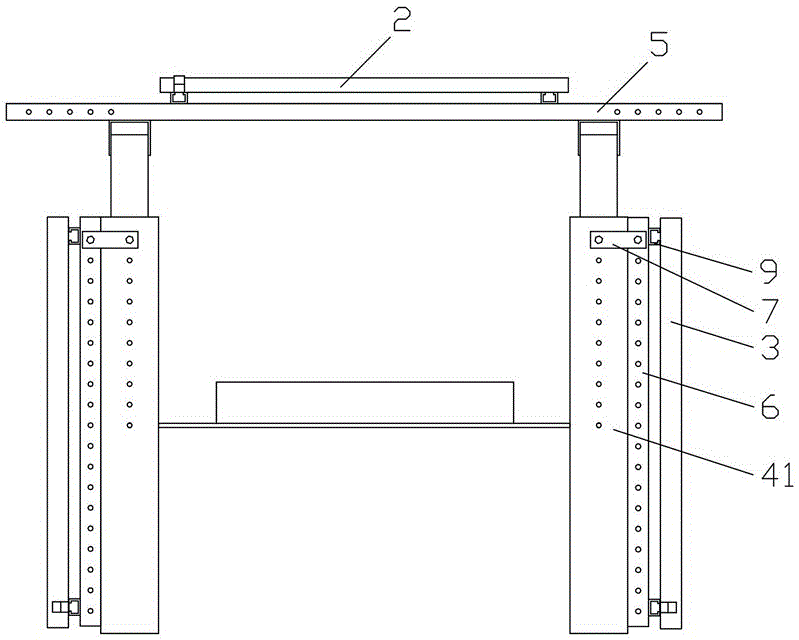

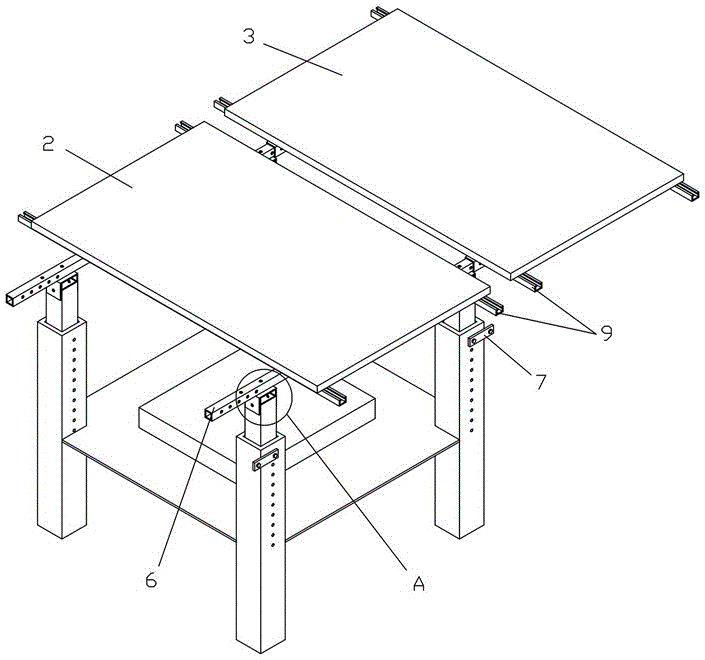

[0036] like Figure 1 to Figure 7As shown, the present invention provides a modular photovoltaic device, including a base 4 and a first photovoltaic assembly 1, a second photovoltaic assembly 2, and a third photovoltaic assembly 3 laid on the base 4 in sequence, and the base 4 includes four Two outrigger assemblies 41, each two outrigger assemblies 41 are respectively provided with a main beam 5, and the two main beams 5 are arranged parallel to each other, and the second photovoltaic module 2 is installed directly above the base 4 through the two main beams 5, The bottom ends of the first photovoltaic module 1 and the third photovoltaic module 3 are provided with two parallel sub-beams 6 . A photovoltaic module 1 and a third photovoltaic module 3 are installed on the left and right sides of the second photovoltaic module 2 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com