High-efficiency soybean meal protein extraction device and method

A protein extraction and high-efficiency technology, applied in the protein composition of vegetable seeds, protein food processing, vegetable protein processing, etc., can solve the problems of increasing the area of equipment used, increasing the cost of equipment purchase, and increasing the occupancy rate of equipment, etc. Achieve the effect of reducing floor space and purchase cost, improving protein extraction rate, and ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

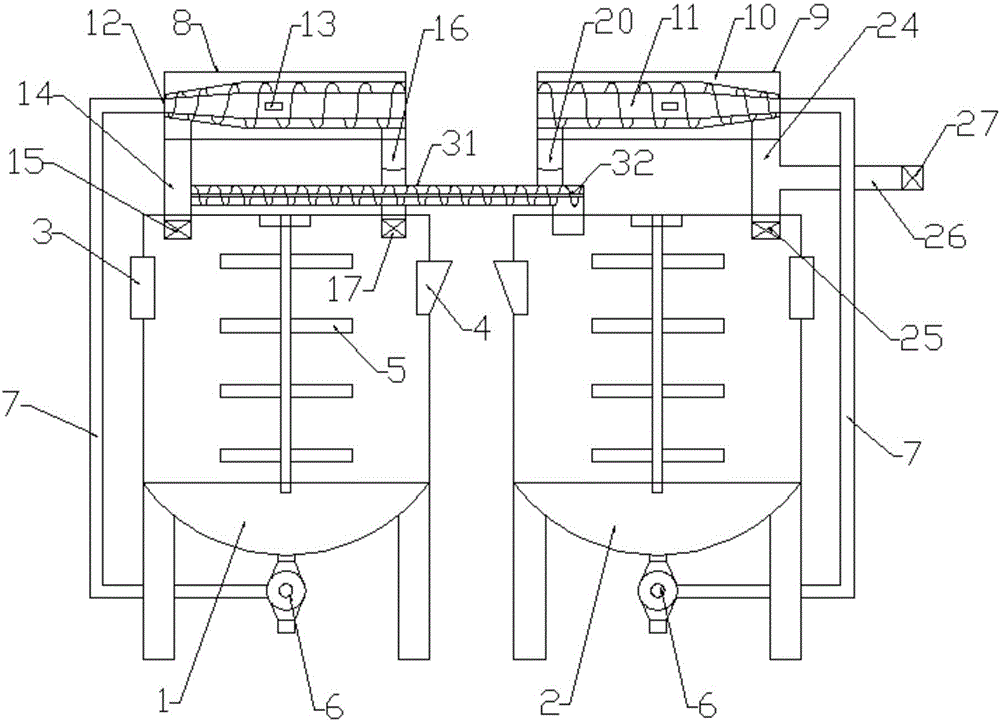

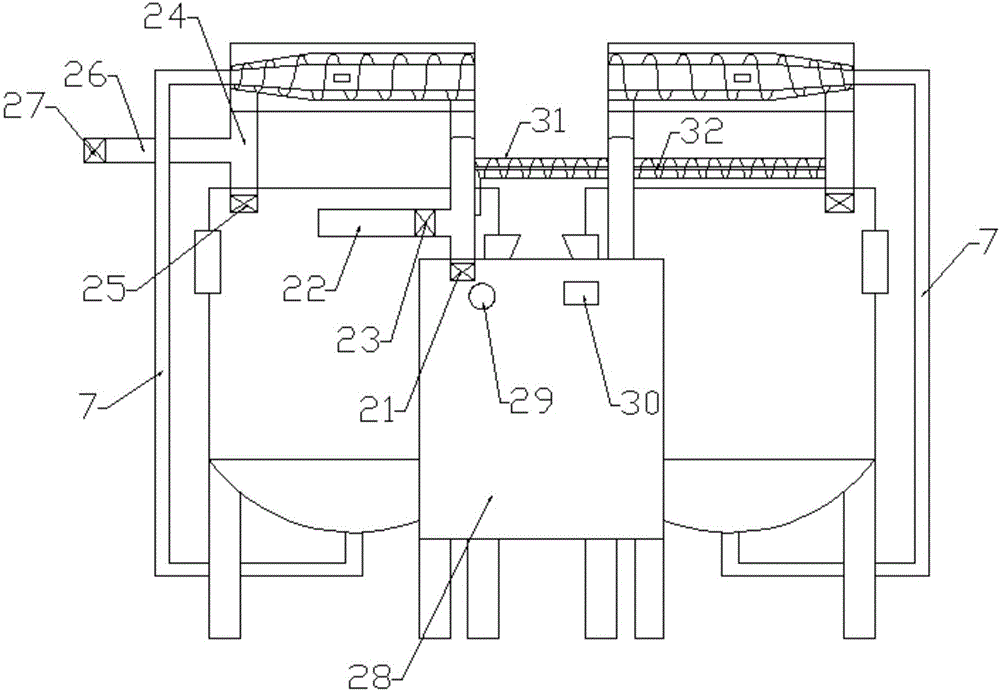

[0037] Such as Figure 4 As shown, the present invention also discloses a high-efficiency soybean meal protein extraction method, which is specifically as follows:

[0038] (1) Primary leaching: add water and soybean meal to the tank A1 in a ratio of 8-9:1 for mixing, and add NaOH solution to it to adjust the pH to 8-8.3, and then stir under the stirring rod 5 Soak for 5-20 minutes, at this time the temperature is controlled at 25-30°C;

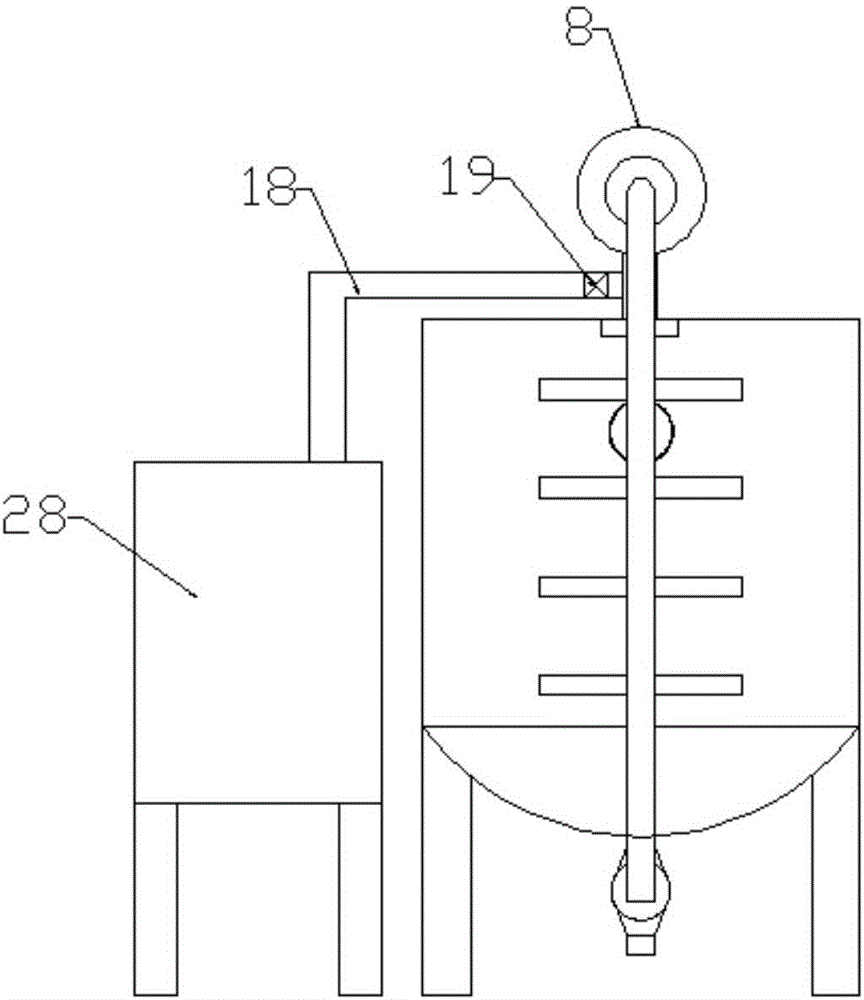

[0039] (2) Separation: The liquid that has been leached once is transported to the separator A8 through the catheter tube 7 for separation. At this time, the valve A15 and the valve C19 are opened, so that the separated liquid can be separated from the clear liquid discharge pipe A16 and the infusion pipe. 18 flows in the aftertreatment tank 28, the solid phase thing that makes separation continue to flow in the tank body A1 from the solid phase thing discharge pipe A14;

[0040] (3) Secondary leaching: mix water and solid phase at a ratio ...

Embodiment 2

[0052] (1) Primary leaching: add water and soybean meal to the tank A1 at a ratio of 9 to 11:1 for mixing, and add NaOH solution to it to adjust the pH to 8.3 to 8.7, and then soak under the stirring of the stirring rod 5-20min, at this time the temperature is controlled at 30-35°C;

[0053] (2) Separation: The liquid that has been leached once is transported to the separator A8 through the catheter tube 7 for separation. At this time, the valve A15 and the valve C19 are opened, so that the separated liquid can be separated from the clear liquid discharge pipe A16 and the infusion pipe. 18 flows in the aftertreatment tank 28, the solid phase thing that makes separation continue to flow in the tank body A1 from the solid phase thing discharge pipe A14;

[0054] (3) Secondary leaching: mix water and solid phase at a ratio of 4.8 to 5.4:1, and continue to add NaOH solution to tank A1 to adjust the pH to 8.3 to 8.7, and then stir it under the stirring rod 5 Soak for 5-20 minutes,...

Embodiment 3

[0065] (1) Primary leaching: Add water and soybean meal to the tank A1 in a ratio of 11-12:1 for mixing, and add NaOH solution to it to adjust the pH to 8.7-9, and then soak under the stirring of the stirring rod 5-20min, at this time the temperature is controlled at 35-40°C;

[0066] (2) Separation: The liquid that has been leached once is transported to the separator A8 through the catheter tube 7 for separation. At this time, the valve A15 and the valve C19 are opened, so that the separated liquid can be separated from the clear liquid discharge pipe A16 and the infusion pipe. 18 flows in the aftertreatment tank 28, the solid phase thing that makes separation continue to flow in the tank body A1 from the solid phase thing discharge pipe A14;

[0067] (3) Secondary leaching: mix water and solid phase at a ratio of 5.4 to 6:1, and continue to add NaOH solution to tank A1 to adjust the pH to 8.7 to 9, and then stir under the stirring rod 5 Soak for 5-20 minutes, at this time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com