Net-free juicer cable of easy cleaning

A juicer and Netease technology, applied in the field of non-Netease cleaning juicers, can solve the problems of very high requirements on the strength of the filter cavity wall, difficult to clean, and reduce the service life of the juicer, and achieve easy cleaning, convenient installation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

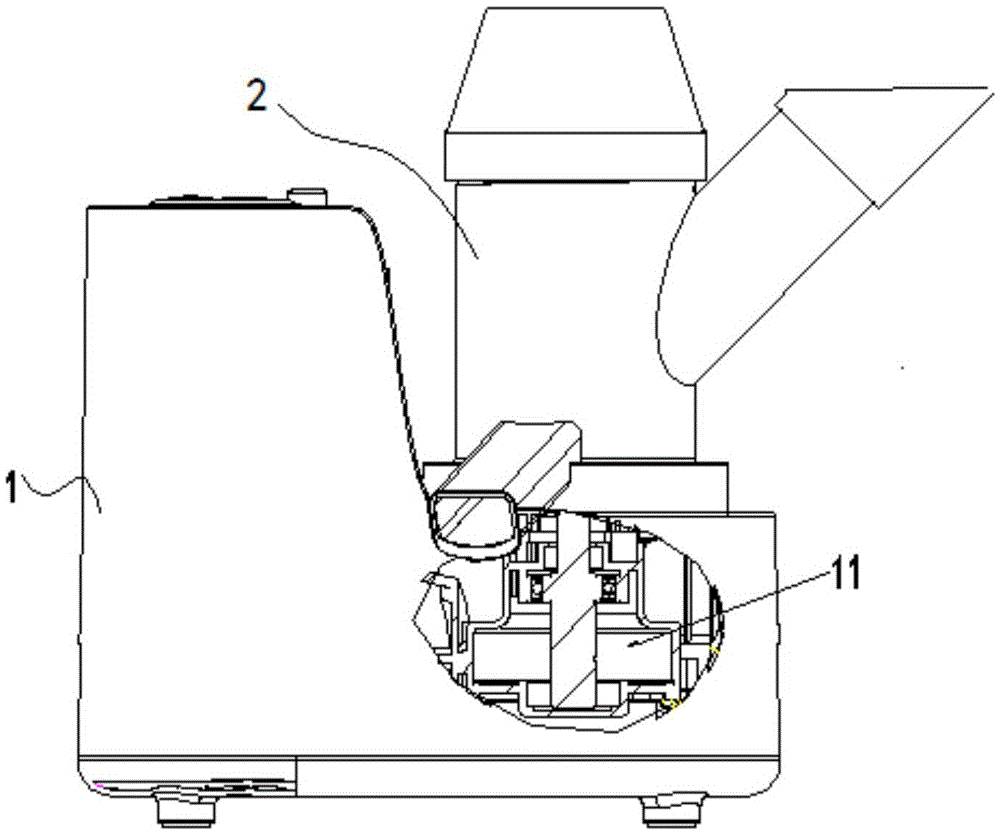

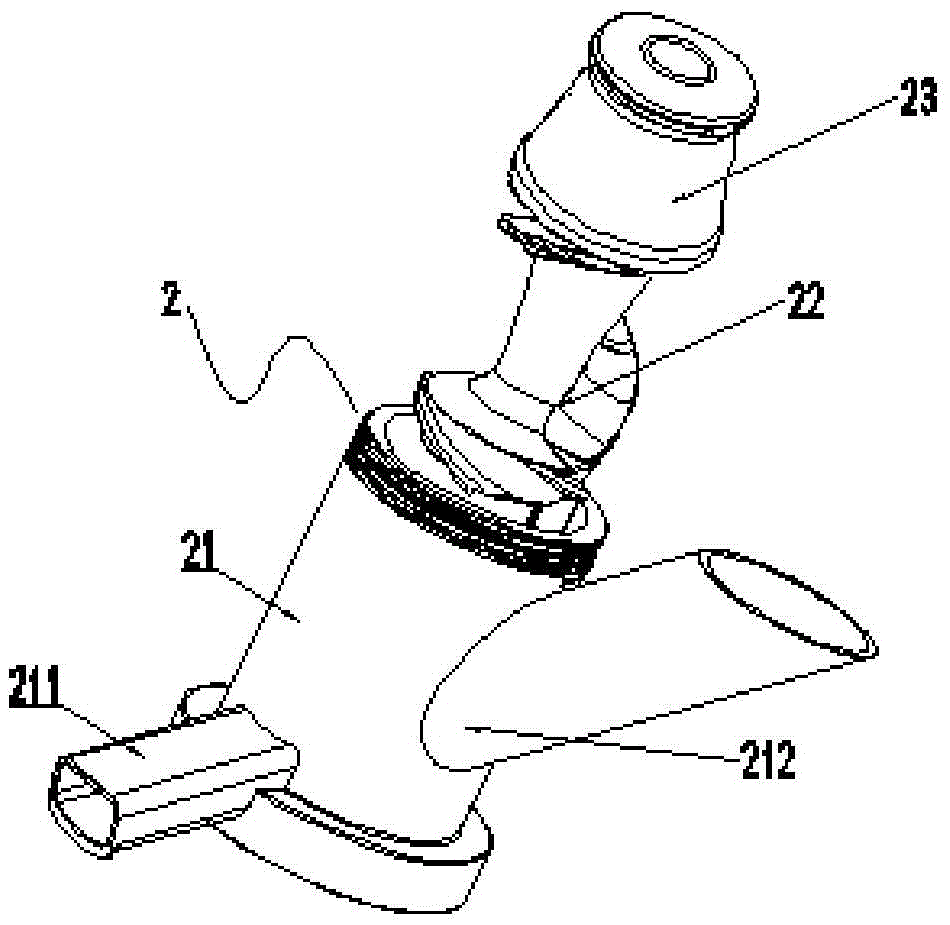

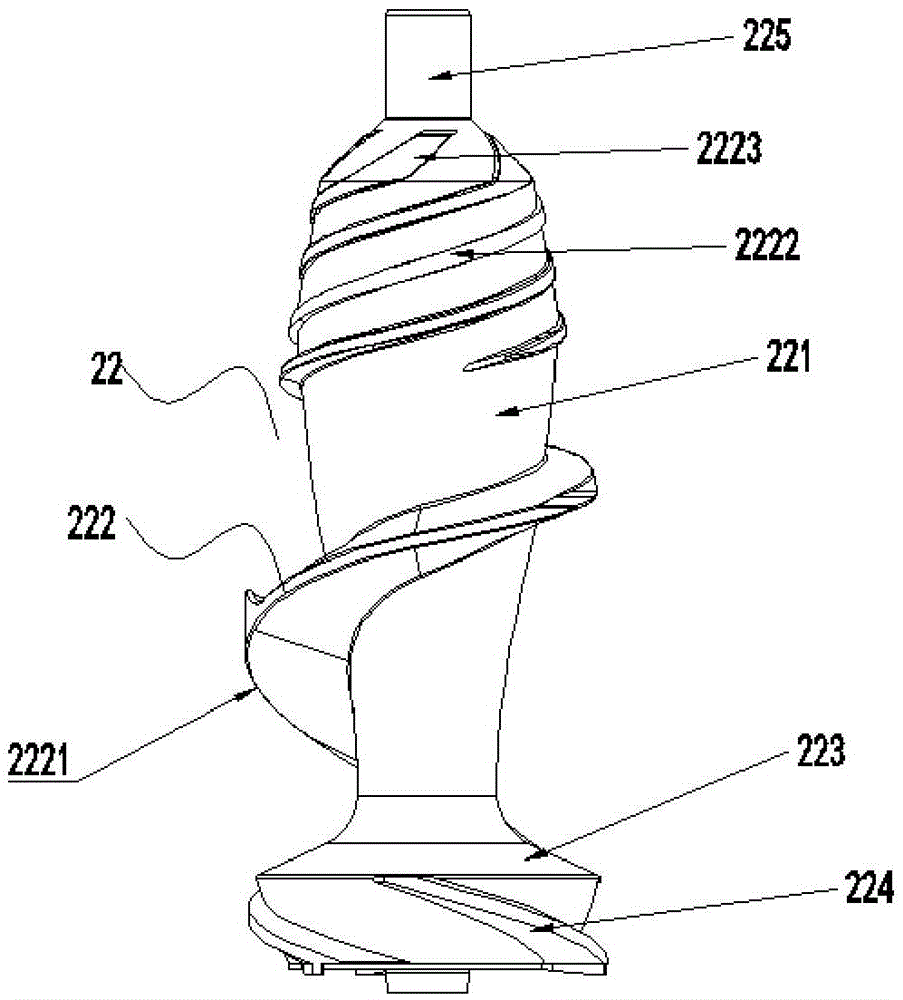

[0048] As the first embodiment of a kind of NetEase cleaning juice extractor described in the present invention, such as Figure 1 to Figure 6 As shown, it includes a matched machine base 1 and a juice extracting assembly 2, wherein the juice extracting assembly 2 includes an extraction cylinder 21 and a screw 22 vertically arranged in the extraction cylinder 21, and a motor 11 is arranged inside the base 1, so that The motor 11 is provided with an output shaft (not shown) that matches the screw 22, and the output torque of the output shaft driven by the motor 11 is preferably 40 N·m, so that the output torque of the output shaft is suitable for the needs of low loads. suitable for soft fruits (eg tomatoes), but also for fruits requiring high loads (eg sugar cane). The lower end of the screw 22 is provided with a connection hole (not shown in the figure) that is compatible with the output shaft, and the output shaft passes through the center of the bottom of the extraction cyl...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is that, as Figure 7 to Figure 9 As shown, the slag discharge hole 233 in this embodiment is located at the center of the top surface of the extrusion cylinder 23 . The center of the slag discharge hole 233 coincides with the axis of the screw 22, so that under the action of the top of the screw, the pomace can be pushed to the slag discharge hole at the center of the top surface in an orderly and smooth manner. The hole wall of the slag discharge hole 233 extends upwards to form a slag discharge channel 236, and the slag discharge column 225 passes through the slag discharge channel 236 to form the slag discharge port 25, thereby raising the slag discharge port 25, thereby facilitating installation and higher The pomace processing device that is compatible with the pomace outlet 25 raises the pomace outlet 25 and increases the pomace discharge distance, so that the pomace has a buffering process in the discharge ...

Embodiment 3

[0097] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 2 is that the inner wall of the slag discharge channel 236 in this embodiment is symmetrically provided with at least two limit blocks 235 that match the slag discharge column 225, and the limit blocks 235 is an arc-shaped structure, and the thickness of the limiting block 235 is the same as the slagging clearance of the slag outlet 25, so that the slagging column 225 is limited by the limiting block 235 to ensure that the slagging column 225 is in the The fruit pomace will not move laterally under the extrusion, thereby ensuring the extrusion and juicing effect of the juicing assembly 2, so that the juice yield of the material is reduced.

[0098] In this embodiment, the filtering gap is 0.5 mm, and the filtering efficiency is high. However, the filtering effect of the filter gap is slightly poor, but because a large amount of pomace produced by squeezing the juice is discharged from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com